Device for Avoiding Shattering of Biomass Pellet Fuel

A technology of biomass pellets and fuel, which is applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of increasing the workload of workers, rebounding or shaking, falling of biomass pellet fuel, etc., to facilitate heat dissipation, improve integrity, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

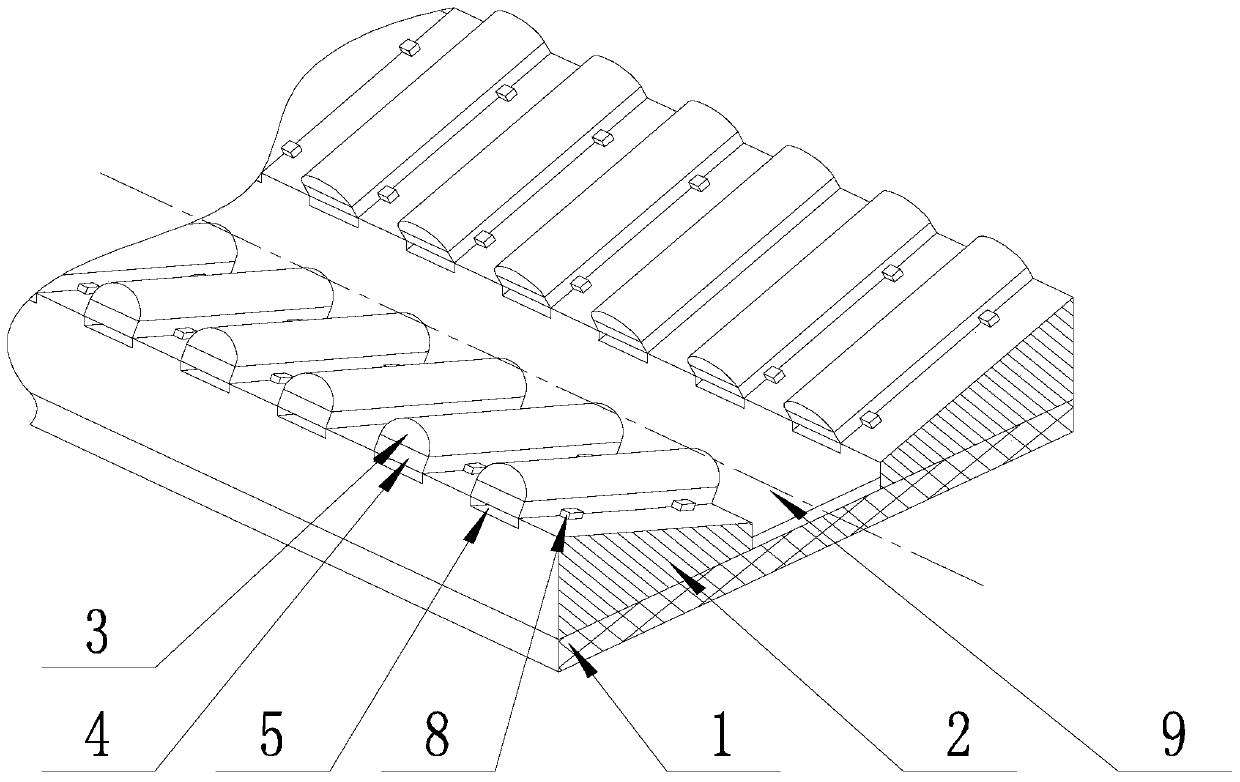

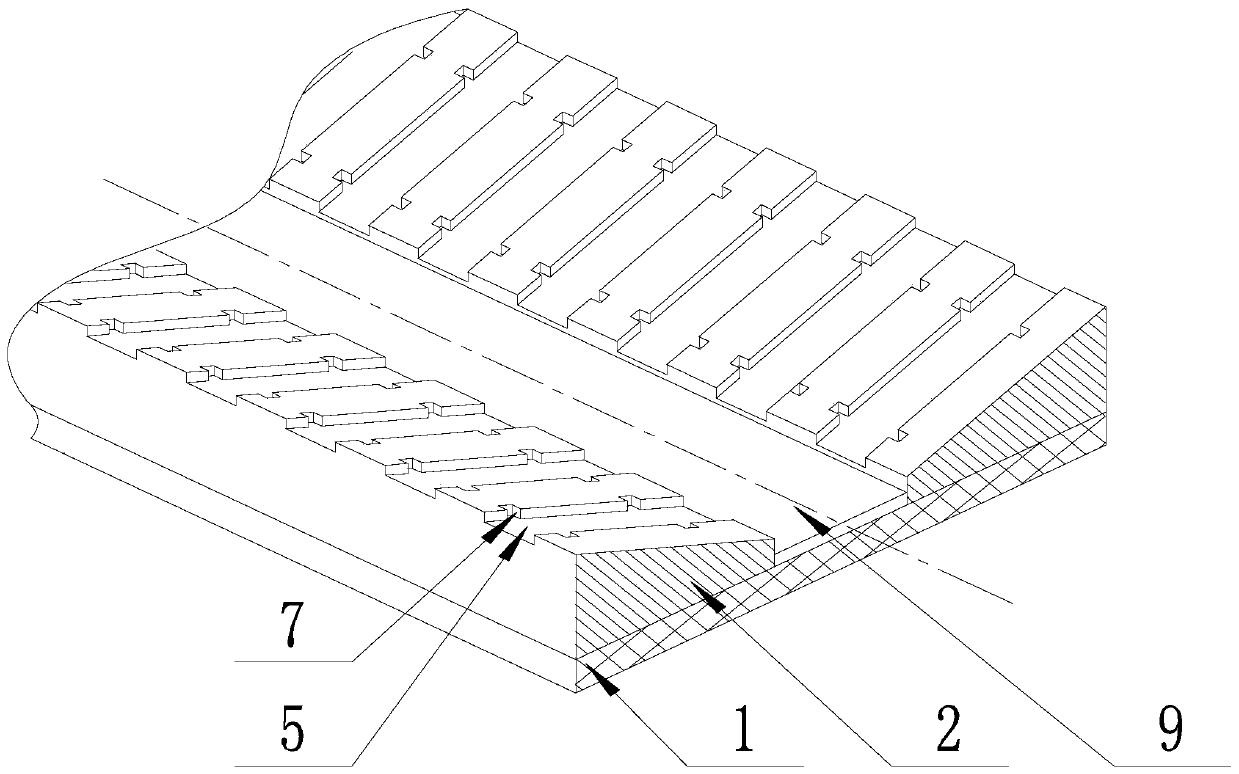

[0035] Such as Figure 1-Figure 5 As shown, the device of the present invention for avoiding biomass particle fuel shake-off includes a conveyor belt 1 driven by a motor, and bars 2 are arranged on both sides of the upper surface of the conveyor belt 1 along its parallel to the conveying direction. The axes are all parallel to the conveying direction of the conveyor belt 1, and the distance from the side of the bar 2 away from the conveyor belt 1 to the conveyor belt 1 gradually decreases from the edge of the conveyor belt 1 to the direction of the center line of the conveyor belt 1, and the length of the bar 2 is the same as that of the conveyor belt 1. The length along the conveying direction is the same.

[0036]Bars 2 are arranged on the upper surface of the conveyor belt 1, so that the biomass pellet fuel on the conveyor belt 1 is always between the bars 2, so as to avoid the situation that a part of the biomass pellet fuel will fall from the conveyor belt, and reduce the...

Embodiment 2

[0041] The present invention is based on embodiment 1, and the present invention is further described.

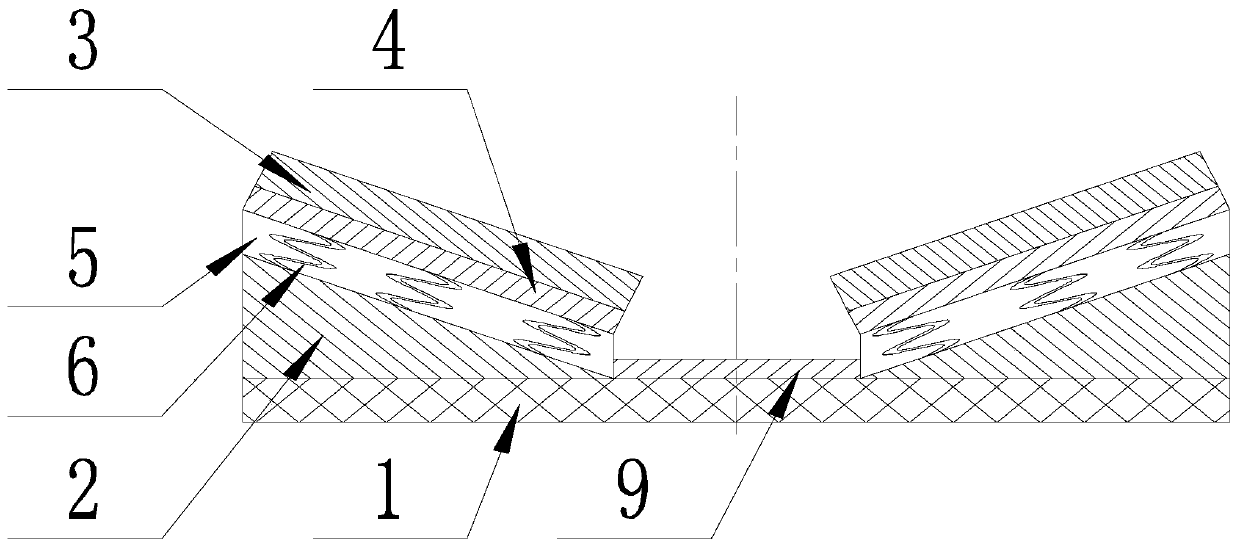

[0042] Such as Figure 1-Figure 5 As shown in the present invention, the device for avoiding biomass particle fuel shaking off is provided with locking grooves 5 on the side of the bar 2 away from the conveyor belt 1, and the axis of the locking grooves 5 is parallel to the guide bar 3 axis, and the number of locking slots 5 on each block 2 is consistent with the number of guide strips 3 on each bar 2, and each of the guide bars 3 cooperates with a locking slot 5;

[0043] Several springs 6 are arranged between the material guide bar 3 and the groove bottom of the corresponding locking groove 5, and the springs 6 are helical cylindrical springs whose axes are all perpendicular to the axis of the locking groove 5, and the springs 6 One end is connected with the groove bottom of the locking groove 5, and the other end of the spring 6 is connected with the side near the botto...

Embodiment 3

[0046] The present invention is based on embodiment 2, and the present invention is further described.

[0047] Such as Figure 1-Figure 5 As shown, the present invention avoids the device of the biomass particle fuel from shaking off, and a clamping block 4 is arranged between the guide bar 3 and the spring 6, and the guide bar 3 is connected with the spring 6 through the clamping block 4, so that The size of the end face connected to the guide bar 3 on the clamping block 4 is consistent with the size of the end face connected to the clamping block 4 on the guide bar 3 and coincides with each other;

[0048] When the spring 6 is in its original state, the end of the locking block 4 away from the material guide strip 3 is located in the locking groove 5 .

[0049] Guide grooves 7 are arranged on the groove wall of the locking groove 5, and the axes of the guiding grooves 7 are all perpendicular to the groove bottom of the locking groove 5. Guide blocks 8 are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com