Disc-type testing, printing and packing machine for inductance products

A product testing and packaging machine technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of automatic processing lines failing to play a protective role, affecting product quality, and taking a long time to improve efficiency and quality. , Improve the quality of processing, the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

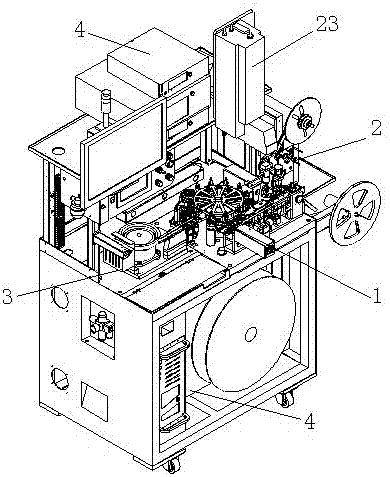

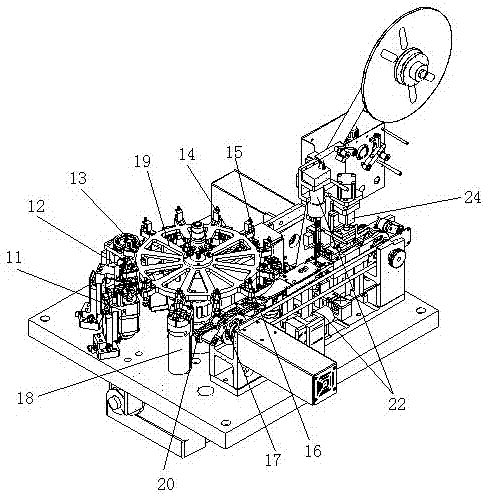

[0028]A disc-type inductance product test printing packaging machine, mainly including a vibrating disc feeding mechanism 3, a main working mechanism, a man-machine combination control system 4 and a sheet metal frame, the vibrating disc feeding mechanism 3 and the main working mechanism are installed in sequence On the sheet metal frame and electrically connected with the man-machine combination control system 4 to form an electric drive connection structure; it is characterized in that the main working mechanism includes a turntable leading mechanism 1 and a packaging leading mechanism 2 adapted to the work of inductive products; the turntable The leading mechanism 1 is mainly composed of a pre-positioning mechanism 11, a direction testing mechanism 12, a rotating mechanism 13, a gear testing mechanism 14, an optical testing mechanism 15, a classification mechanism 16, a calibration positioning mechanism 17, and a cleaning mechanism 18, which are installed around the turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com