Precision vacuum nozzle mechanism

A vacuum suction nozzle and precise technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of difficult to ensure the relative position and installation accuracy of suction nozzles, adapters and products, reduce product test yield, and easily damage sucked products. and other problems, to achieve the effect of improving product test yield, correct installation direction, and smooth plugging and unplugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

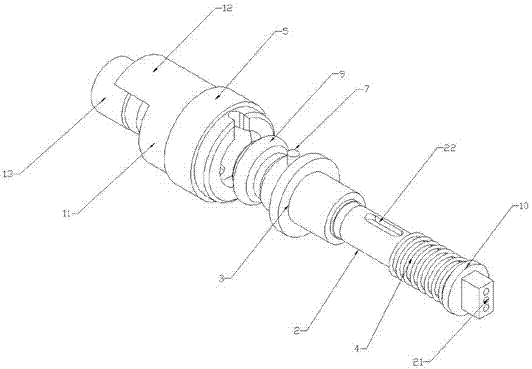

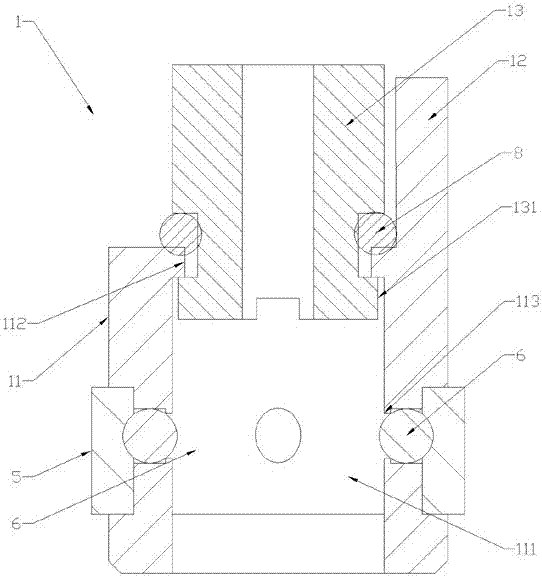

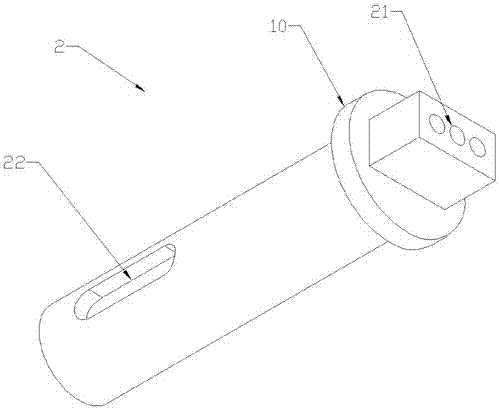

[0019] Such as Figure 1 to Figure 4 As shown, the specific embodiment of the present invention is: the present invention includes an adapter assembly 1, a nozzle body 2 and a nozzle sleeve 3, the adapter assembly 1 includes an adapter seat 11, and the adapter seat 11 is used In connection with an external vacuum system, the nozzle sleeve 3 is used to connect the nozzle body 2 and the adapter assembly 1; the present invention adopts a split nozzle structure, that is, the nozzle body 2 It is not directly connected to the external equipment or vacuum system through threads as in the prior art, but after adding the adapter assembly 1 to connect with the external equipment or vacuum system, the suction nozzle tube body 2 is connected to the adapter base 11, and a buckle connection module is provided between the nozzle sleeve 3 and the adapter base 11, and the nozzle sleeve 3 and the nozzle body 2 are used as a As a whole, the whole body is inserted and pulled out in the adapter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com