Fermentation control method

A control method and pressure control technology, applied in beer fermentation methods, biochemical equipment and methods, beer brewing, etc., can solve the problem of affecting the control action time and control effect, inability to extract production data in time, inaccurate fermentation temperature control, etc. problems, to achieve the effect of simple and sensitive adjustment methods, improved measurement accuracy and system stability, and flexible control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

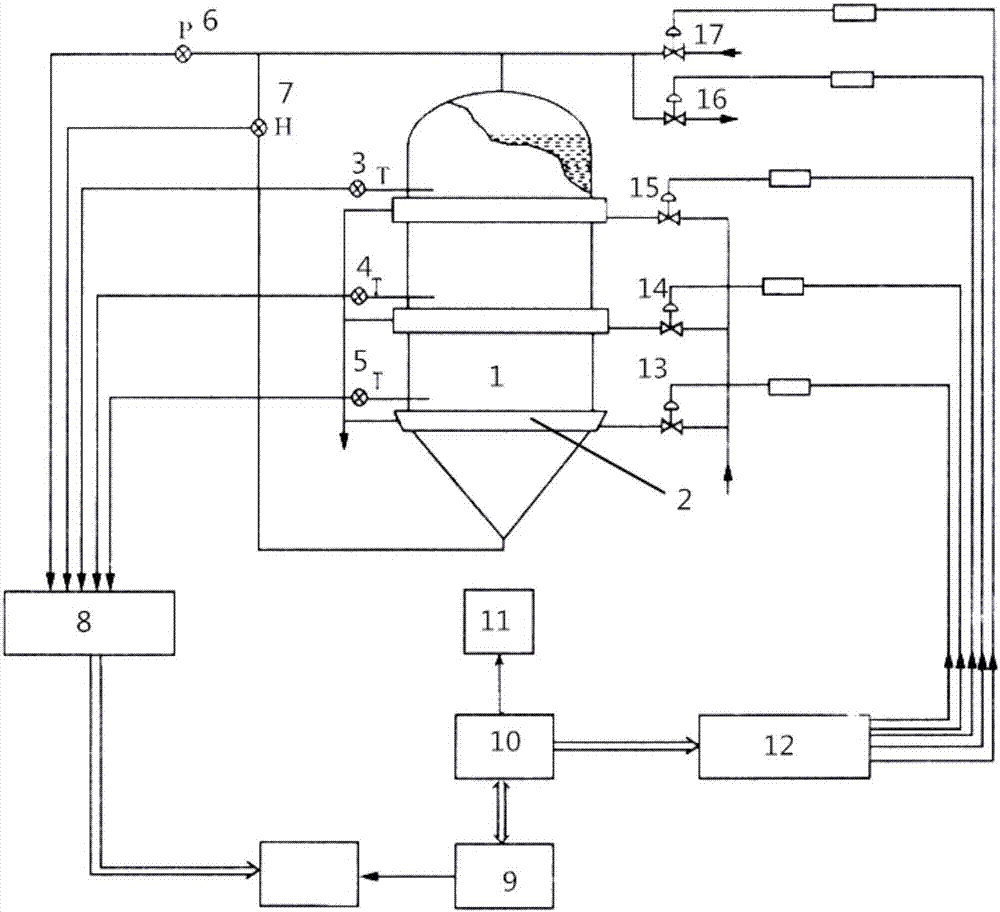

[0020] Refer to attached figure 1 , The beer fermenting device in the present embodiment comprises tank body 1, and the periphery of tank body is wrapped with insulating material, and tank body itself is equipped with three sections of cooling jackets 2, so that cooling with glycol or alcohol solution. The upper, middle and lower sections of the tank body are respectively provided with temperature detection devices 3, 4 and 5. The upper part of the tank is provided with a pressure detection device 6, the bottom of the tank is provided with a liquid level detection device 7, and the top of the tank is provided with an inflation valve 16 and an exhaust valve 17. The tank body is a cylinder as a whole, and the bottom is a cone. The detection device is electrically connected with the computer 10 system through the access channel 8 and the hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com