Environment-friendly brass alloy for casting and manufacturing method thereof

A brass alloy, environmentally friendly technology, applied in the field of alloys, can solve the problems of high casting defect rate, poor stress corrosion resistance of silicon brass, difficulty in recycling waste materials, etc., and achieve good mechanical properties and casting performance, and stress corrosion resistance Good, polished and weldable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

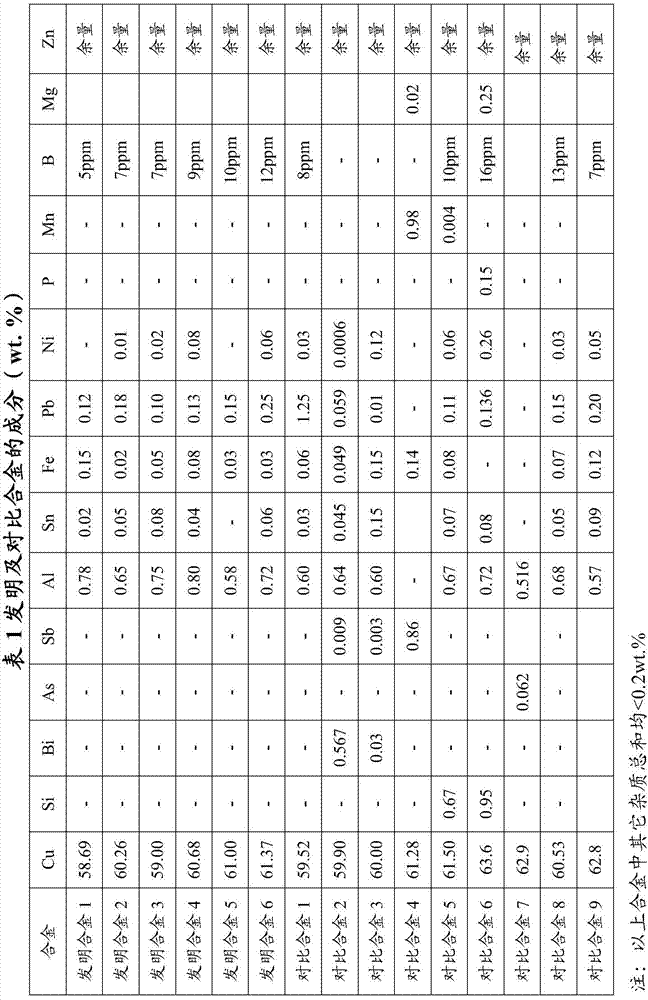

[0041] Preparation and component analysis of embodiment 1 alloy of the present invention and contrast alloy

[0042] a. Preparation and component analysis of alloy 1-6 of the present invention

[0043]Alloy 1-6 of the present invention is prepared according to the following method: take brass waste and old material, electrolytic copper, Zn, Al, Sn, Ni, Pb and copper-iron master alloy according to the mass percentage of alloy composition of the present invention, wherein in the copper-iron master alloy The content of Cu is 90-95wt.%. Before each furnace is smelted, an appropriate amount of non-borax slag cleaning agent is added to the furnace bottom, and then nickel, copper-iron intermediate alloy, and brass scrap are added until 1 / 4 of the brass scrap has been melted. When adding electrolytic copper on the surface, after all the materials are completely melted, add Zn, Al, Sn, Pb in turn, and stir well, after the metal is completely melted, heat up to remove the slag, and ...

Embodiment 2

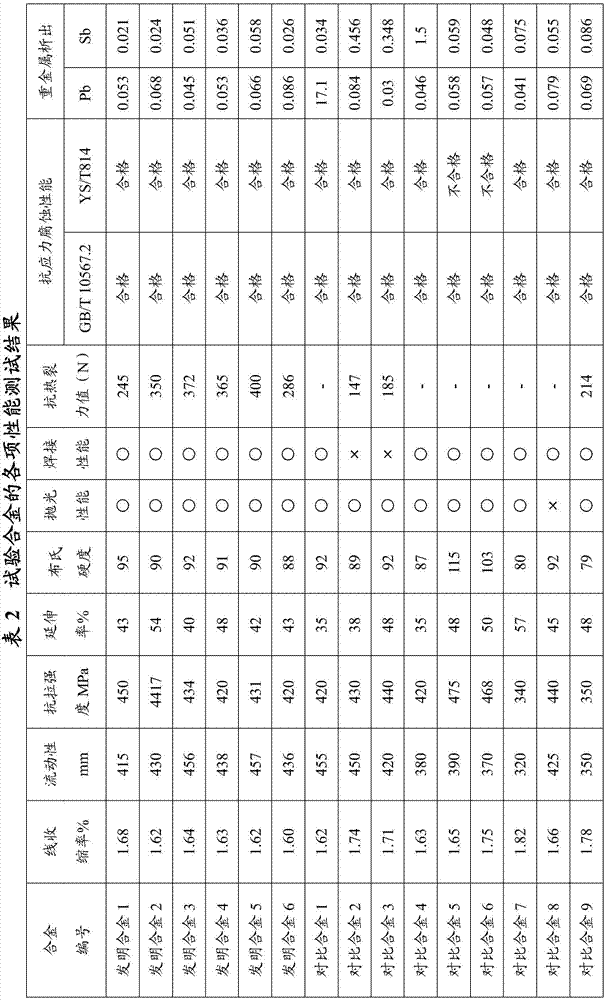

[0050] The performance detection of embodiment 2 alloy of the present invention and contrast alloy

[0051] The properties of the alloys of the present invention and comparative alloys obtained from the above preparation examples will be tested below. The specific performance testing items and methods are as follows. Please refer to Table 2 for the testing results.

[0052] 1. Casting performance

[0053] Bar sample: used to determine the linear shrinkage of the alloy, the lower the linear shrinkage, the stronger the alloy's resistance to thermal cracking. The alloy melt is cast on a bar-shaped sample mold with a length of 200 mm at a temperature of 1050 ° C. After cooling, the linear shrinkage rate is calculated by measuring the gap distance between the mold and the alloy sample.

[0054] Spiral sample: The alloy melt is cast on the spiral sample mold at a temperature of 1050°C, and the flow length of the alloy melt is measured to measure the fluidity of the alloy. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com