Bottom-through top-ring joint

A link and outer ring plate technology, applied in the engineering field, can solve problems such as large residual stress, brittle failure, affecting architectural beauty and indoor area utilization, and achieve the effect of facilitating construction and avoiding excessive space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

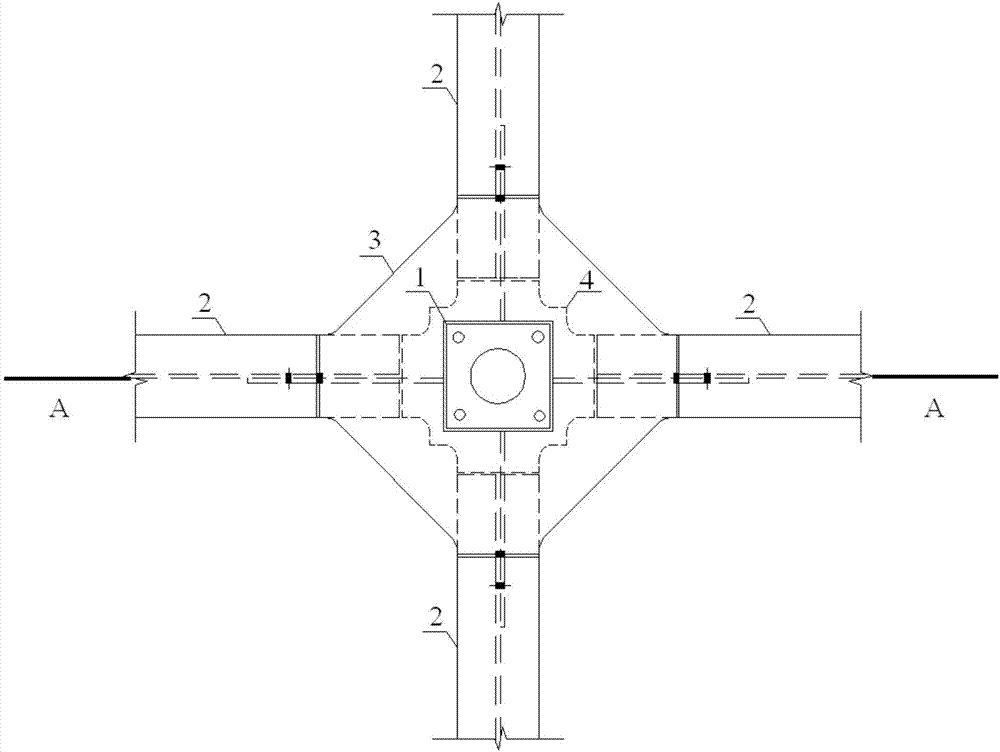

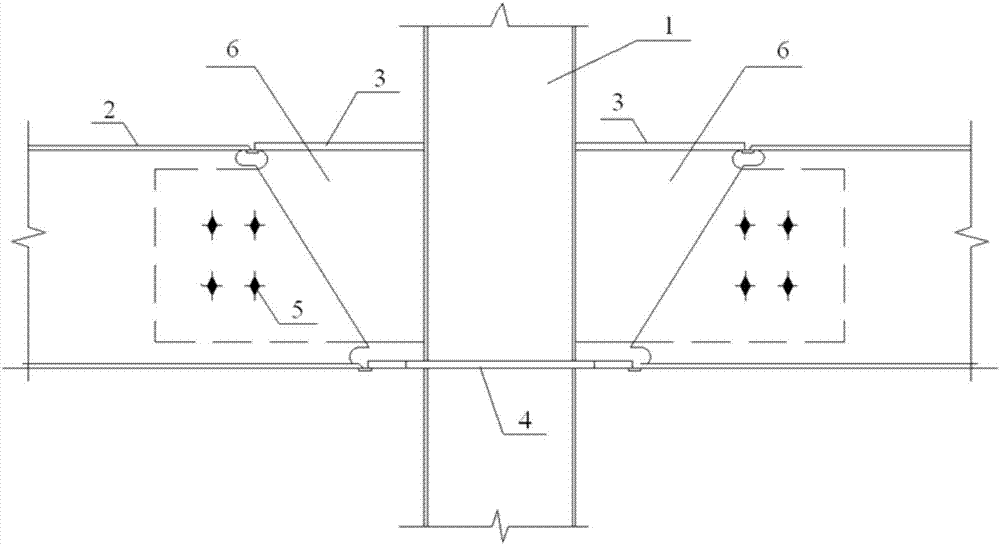

[0019] Such as Figure 1 to Figure 5 , a lower-through-upper-link node that takes up less space, including an H-shaped steel beam connected to a square concrete-filled steel tube column 1, an upper outer ring plate 3, a lower through-wall partition 4, a web connecting plate 6 and a friction type High-strength bolts5.

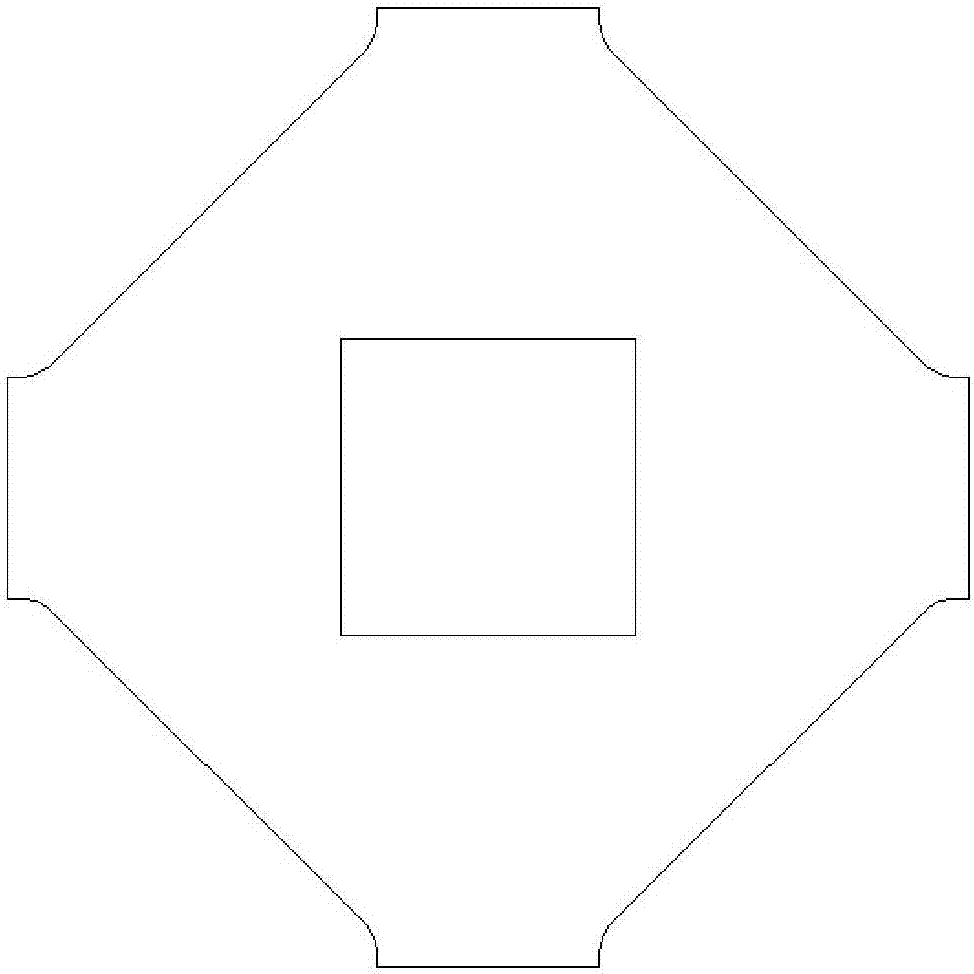

[0020] The upper part of the node is in the form of an outer ring plate, such as image 3 As shown, the upper outer ring plate 3 is provided with an overhanging section with the same width as the upper flange of the H-shaped steel beam, and the overhanging section adopts a circular arc transition. The upper flange plate of the H-shaped steel beam and the upper outer ring plate 3 shall adopt full penetration groove welds.

[0021] The upper end of the web end of the H-shaped steel beam 2 is designed as an arc-shaped port. The lower part of the node ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com