Synergetic fracturing method for main crack and complex crack network of large channel

A technology of main fractures and large channels, which is applied in the field of oil and gas field development and research, can solve the problems of suppressing formation oil and gas production, wasting diversion capacity, and small diversion capacity, so as to enhance reservoir fluid flow capacity, improve reliability and success rate , the effect of enhancing oil and gas recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

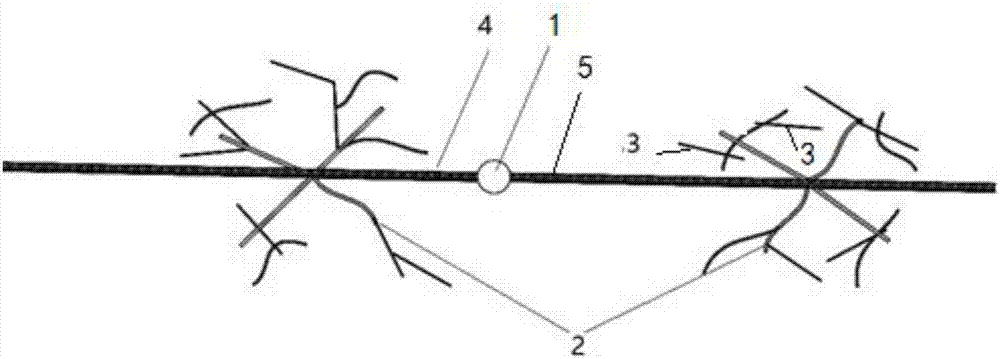

[0081] The application of "rural road network + expressway" model fracturing technology in vertical wellbore, that is, a method of coordinated fracturing of large channel main fractures and complex fracture network, includes the following steps:

[0082] (1) Fractures forming a complex fracture network:

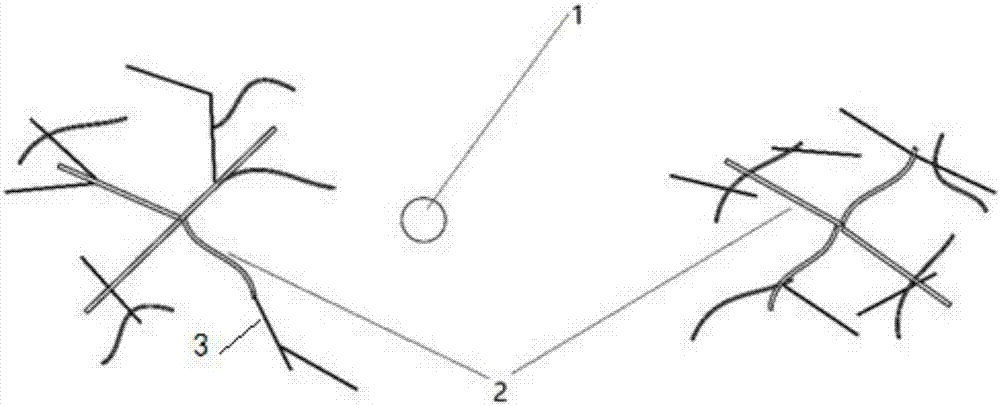

[0083] Prepare pre-fluid for diversion fracturing, and pump it into the formation under the pumping pressure higher than the fracture pressure of the reservoir: fractures forming complex fracture network; if attached figure 1 shown in the original fracture of the diverted fracturing;

[0084] In the step (1), the prefluid used for steering fracturing is clear water fracturing fluid, slick water or live linear glue fracturing; the particle size of the proppant is 80 / 100 mesh;

[0085] Add proppant to the pad to form a mixed pad, pump it into the fractures of the complex fracture network, the sand ratio is 4%, and the sand ratio is the ratio of the total volume of proppant to ...

Embodiment 2

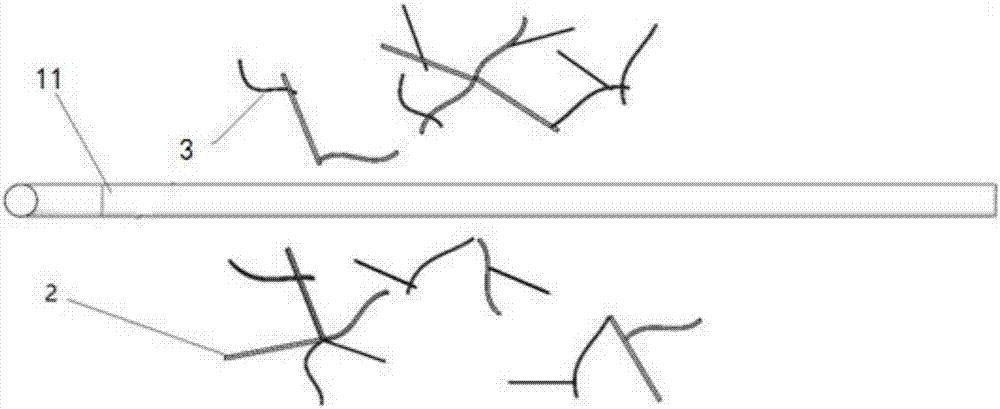

[0111] As described in Example 1, a method for synergistic fracturing of large-channel main fractures and complex fracture networks, the difference is that the method is applied to the "rural road network + expressway" mode fracturing technology in the wellbore of a horizontal well. The point is that,

[0112] The construction well in the step (1) is a horizontal well, as attached image 3 shown;

[0113] In the step (10), repeat the steps (7) to (9) 3 times to form 3 main fractures with large channels to maximize the fluid flow capacity of the reservoir and improve oil and gas recovery, as shown in the attached Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com