Formwork jumbo for full face construction of pipe gallery and construction method thereof

A formwork trolley and full-section technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of pipe gallery water seepage, many construction procedures, and low construction efficiency, and achieves high technical level and standardized management. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

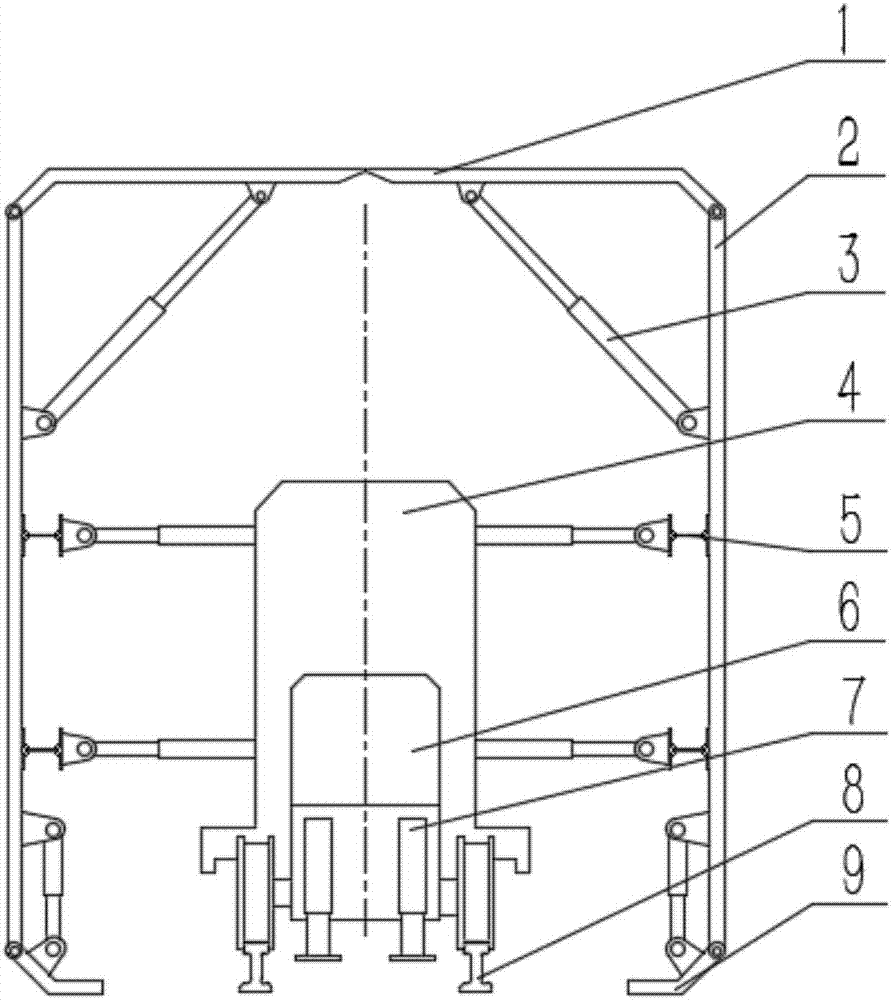

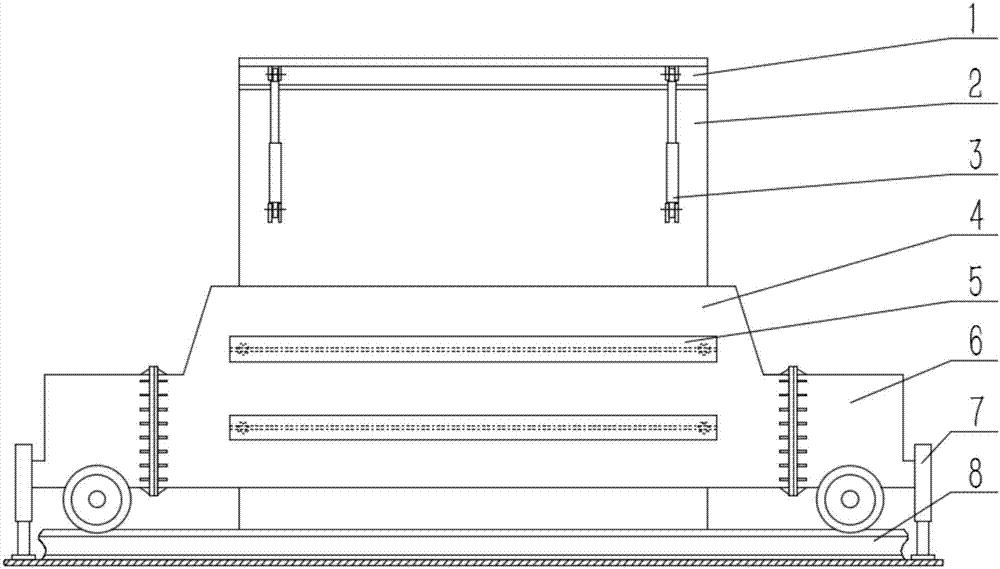

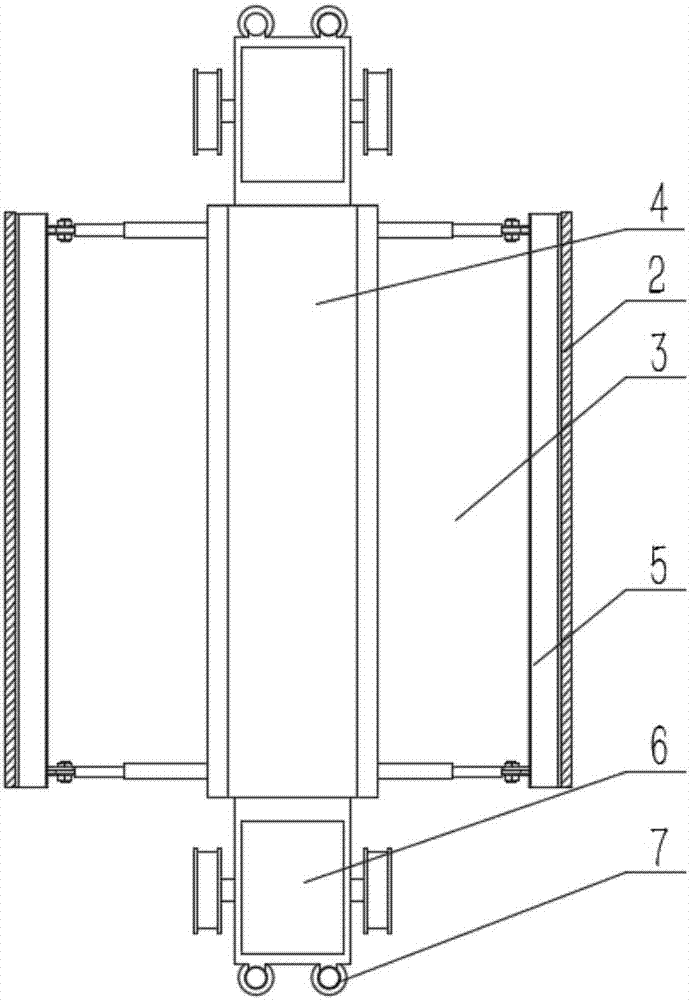

[0028] The present invention adopts a modular structure design for the formwork trolley for full-section construction. According to the construction production organization and design requirements, the length of the formwork module is determined, and assembled in sections to form a module and a support system. The formwork trolley is composed of longitudinal beams in the middle, formwork parts, formwork support devices, hydraulic mechanisms, etc. The longitudinal beam is supported at both ends, and the formwork system connected with the longitudinal beam is used for overall height adjustment and positioning. Longitudinal beams are co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap