Novel combined crankshaft mechanism of small aviation piston engine

A piston engine, combined technology, applied in the direction of engine components, crankshaft, shaft, etc., to achieve the effect of improving rigidity and strength, compact and simple structure, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

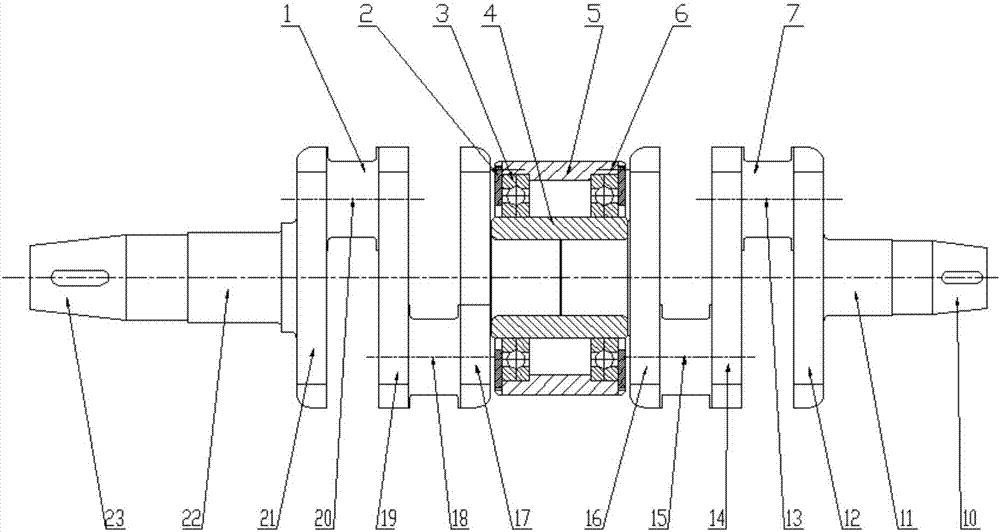

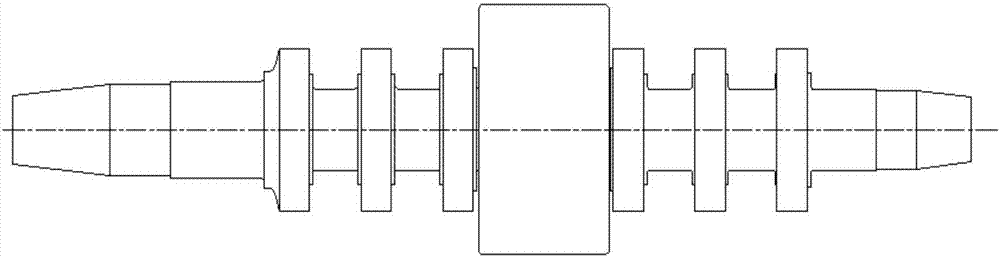

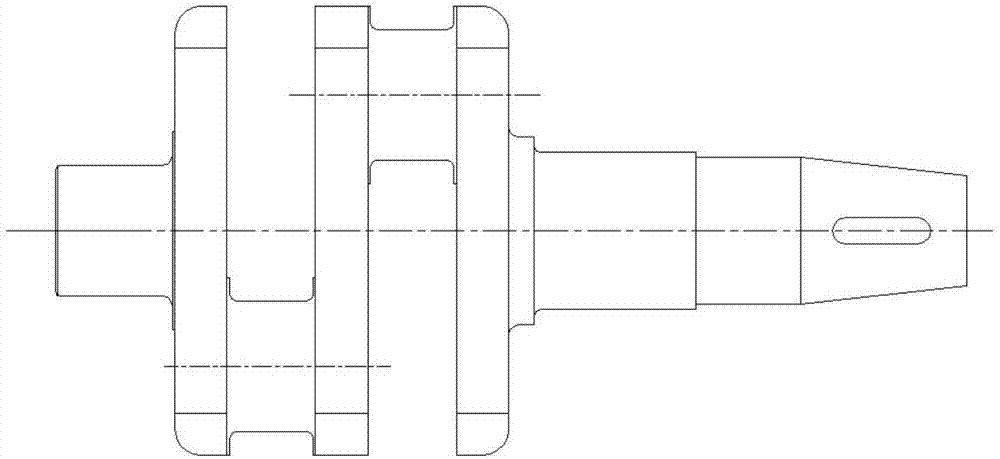

[0021] The following examples refer to the appended figure 1 -8.

[0022] The invention provides a novel combined crankshaft mechanism of a small-sized aviation piston engine, which is a new type of crankshaft mechanism of a small-sized aviation piston engine opposed to four cylinders, such as figure 1 , 2 As shown, the crankshaft mechanism includes front, middle and rear main shaft supports arranged at both ends and the middle of the crankshaft, a crank unit is arranged between every two main shaft supports, and each crank unit includes three cranks arranged in parallel, Connecting rod journals are arranged between the cranks, and the centers of connecting rod shaft diameters of two adjacent crank throws are respectively arranged at the upper and lower ends of the crank. The specific components are: front crank throw unit 1, bearing end cover 2, bearing 3, butt sleeve 4, bearing seat 5, screw 6 and rear crank throw unit 7. The crank throw unit 1 of the front section and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com