Energy-saving continuous drying equipment

A drying equipment, continuous technology, applied in the field of energy-saving continuous drying equipment, can solve the problems of waste of resources, high energy consumption, no consideration, etc., and achieve the effect of small air leakage rate, small volume, and concentrated heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described below in conjunction with specific embodiments.

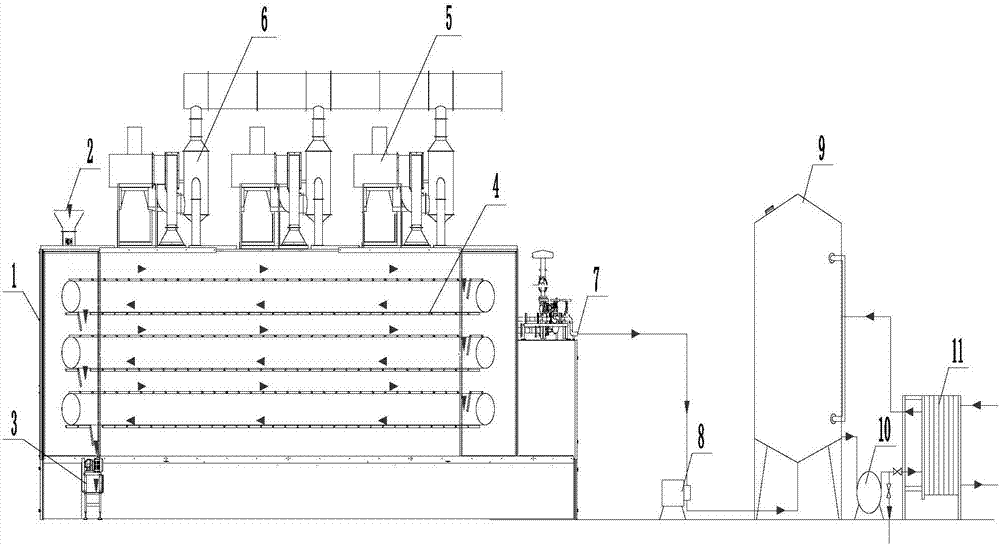

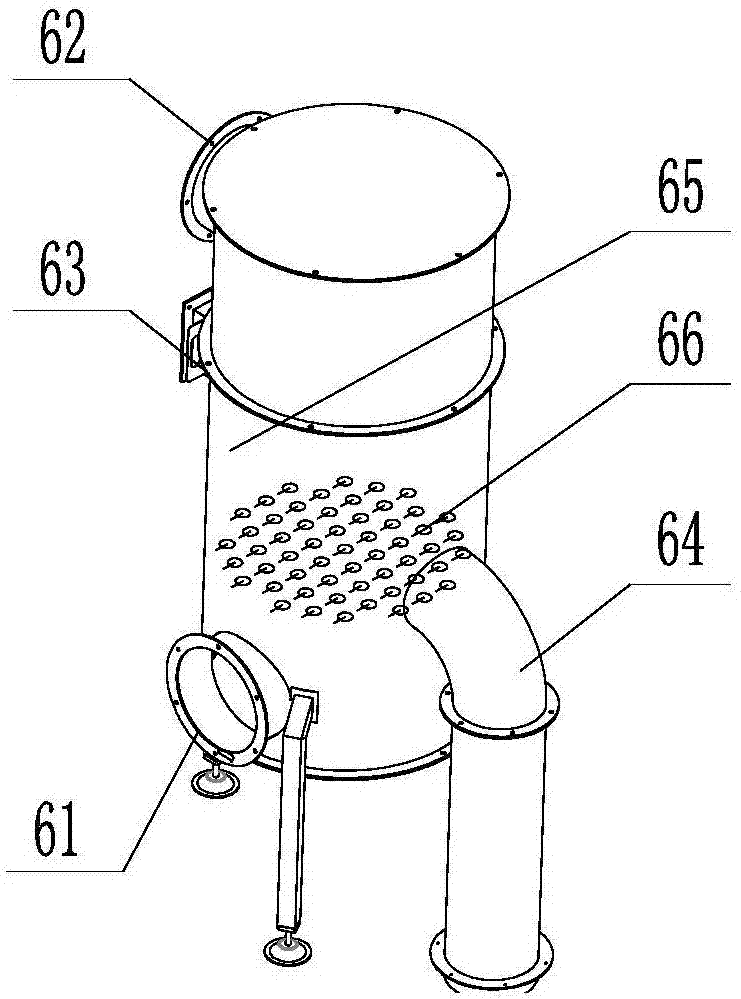

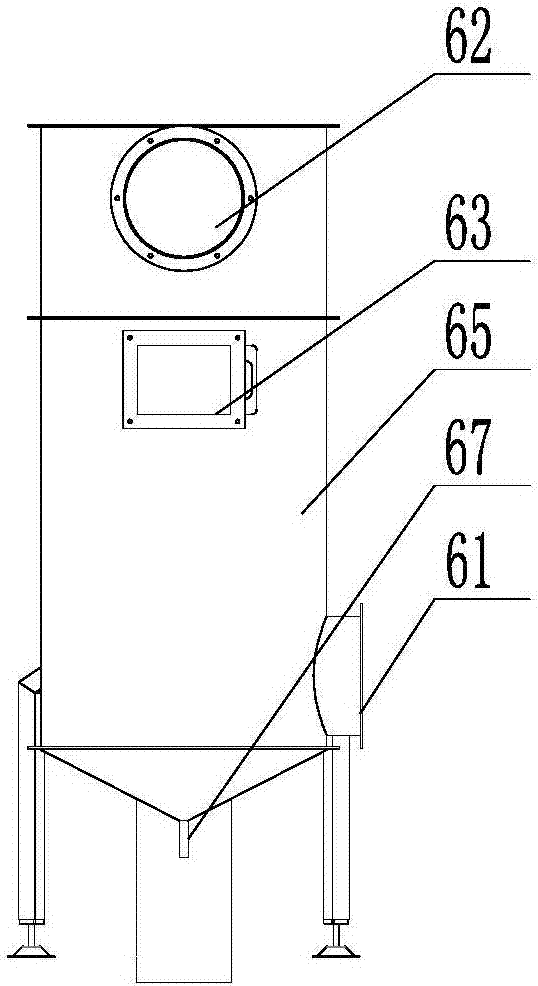

[0026] refer to Figure 1 to Figure 5 , an energy-saving continuous drying equipment proposed by the present invention, including: a heat preservation oven, a conveying mechanism, and a waste heat recovery mechanism for dehumidifying hot air.

[0027] The heat preservation oven 1 has a raw material inlet 2 , a raw material outlet 3 , and a steam heating mechanism for heating the air in the heat preservation oven 1 , and the raw material inlet 2 is located above the raw material outlet 3 .

[0028] There is a distributor at the raw material inlet 2, which is equipped with an air lock. This design enables the distributor to achieve uniform distribution in the width direction, and at the same time realizes the sealing of the raw material inlet 2, and solves the problem of the raw material inlet opening. Wind problem, reduce heat leakage, contribute to energy saving.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com