Inlet manifold sensor structure

A technology for intake manifolds and sensors, which is applied to instruments, measuring devices, etc., can solve problems such as low utilization of installation space and complex processes, and achieve the effects of reducing process costs, firm connections, and reduced processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

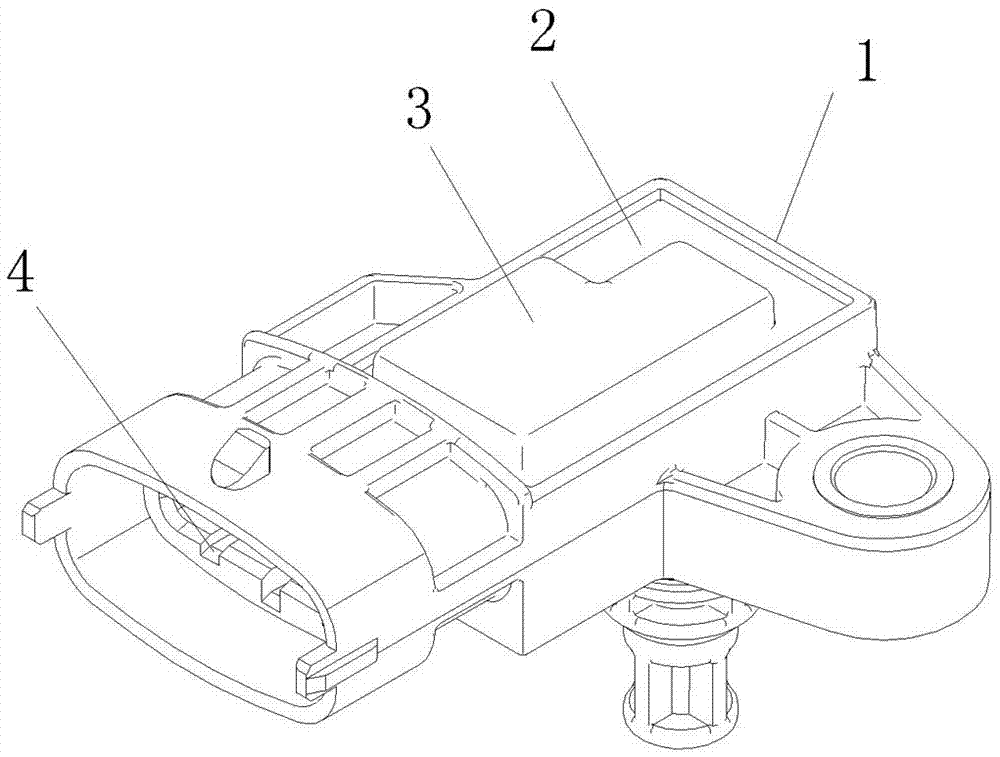

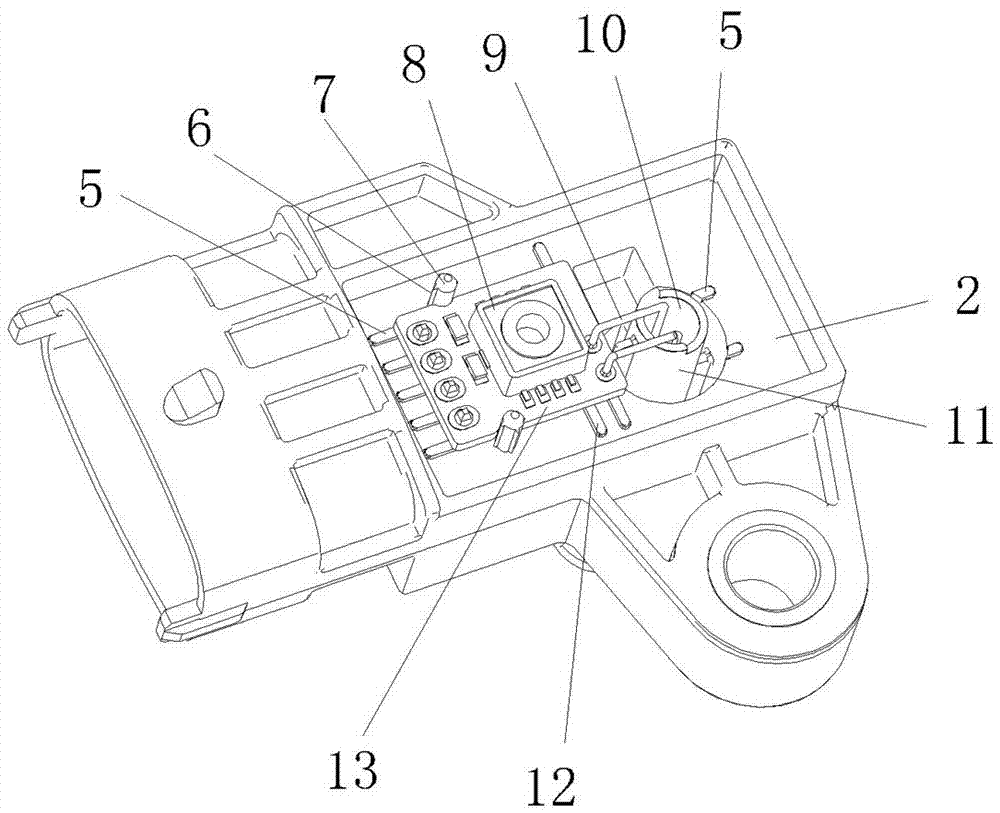

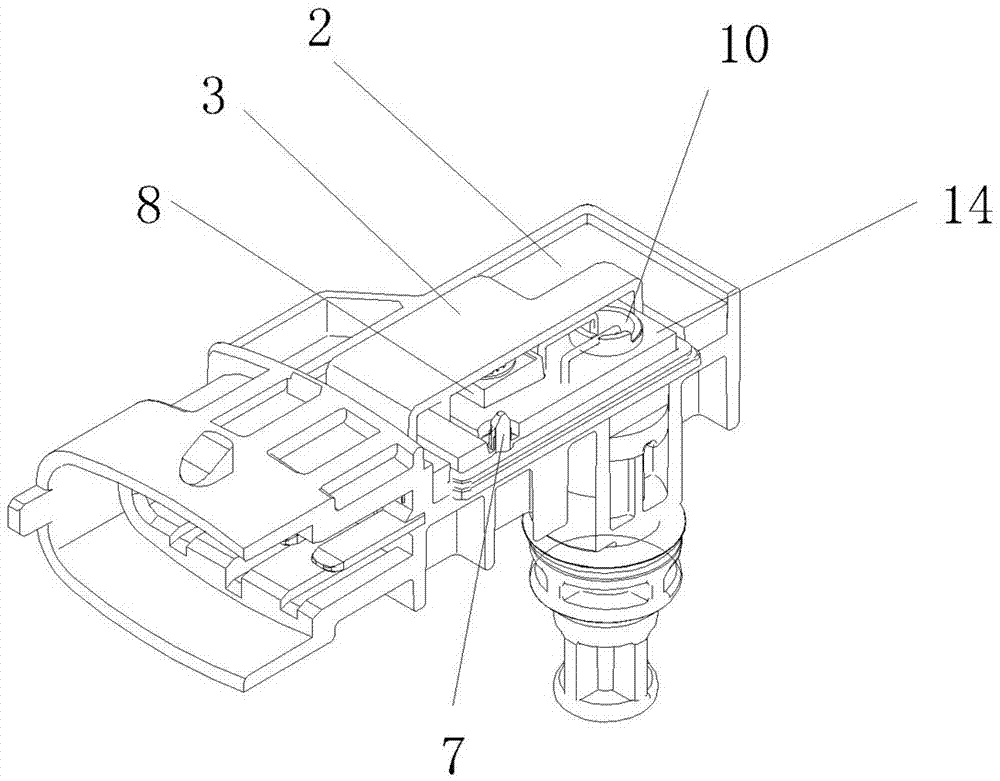

[0023] Such as figure 1 and 2 As shown in and 3 and 4, an intake manifold sensor structure includes a housing 1, and a mounting surface 2 is provided on one side of the housing 1, and the mounting surface 2 is recessed downward to form an open type that can accommodate glue filling. space. An airflow guide pipe 11 is connected below the installation surface 2 . One end of the airflow guide pipe 11 protrudes above the installation surface 2, and the pressure airflow is pressed in from the bottom of the airflow guide pipe 11, and flows out from the air outlet 10 of the airflow guide pipe 11 above the installation surface. A temperature sensitive element 18 is installed in the lower half of the airflow guiding pipe 11 , and the connecting wire 9 of the temperature sensitive element 18 is led out from the airflow guiding pipe 11 .

[0024] A circuit board 13 is installed outside the airflow outlet 10 of the airflow guide tube, and the circuit board 13 is connected to an externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com