Engine hydrogen production device and method thereof

A hydrogen production device and engine technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of increased energy consumption of vaporized fuel and difficulties in the design of automobile installation, and achieves convenient installation, simple installation and design, and heat dissipation. exchange full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] Example.

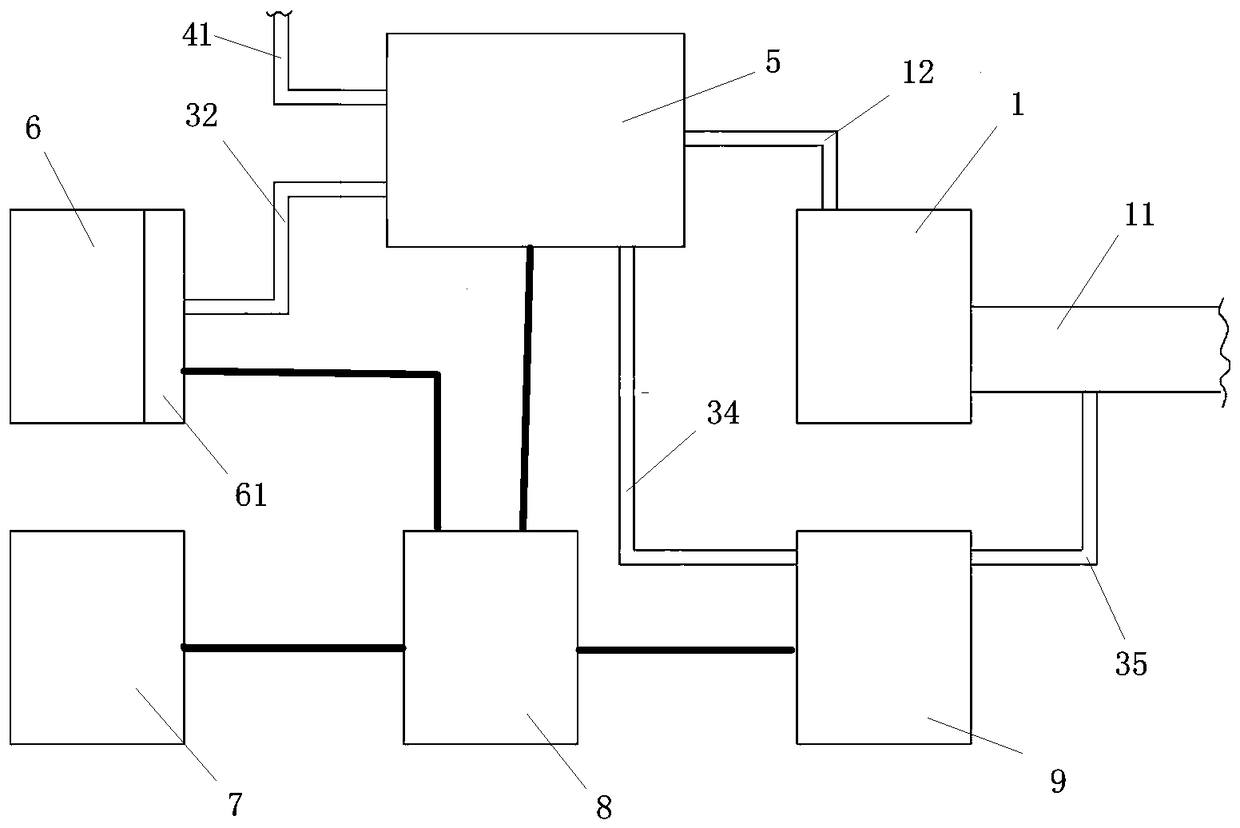

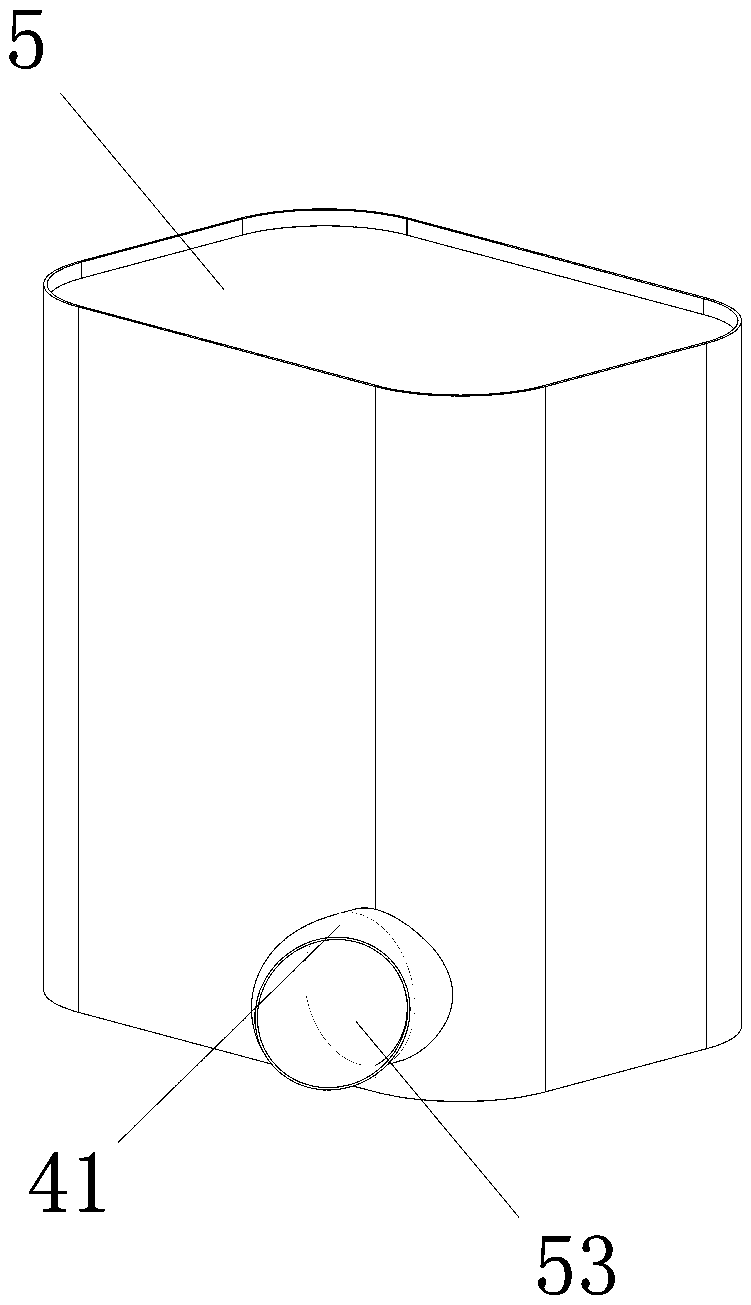

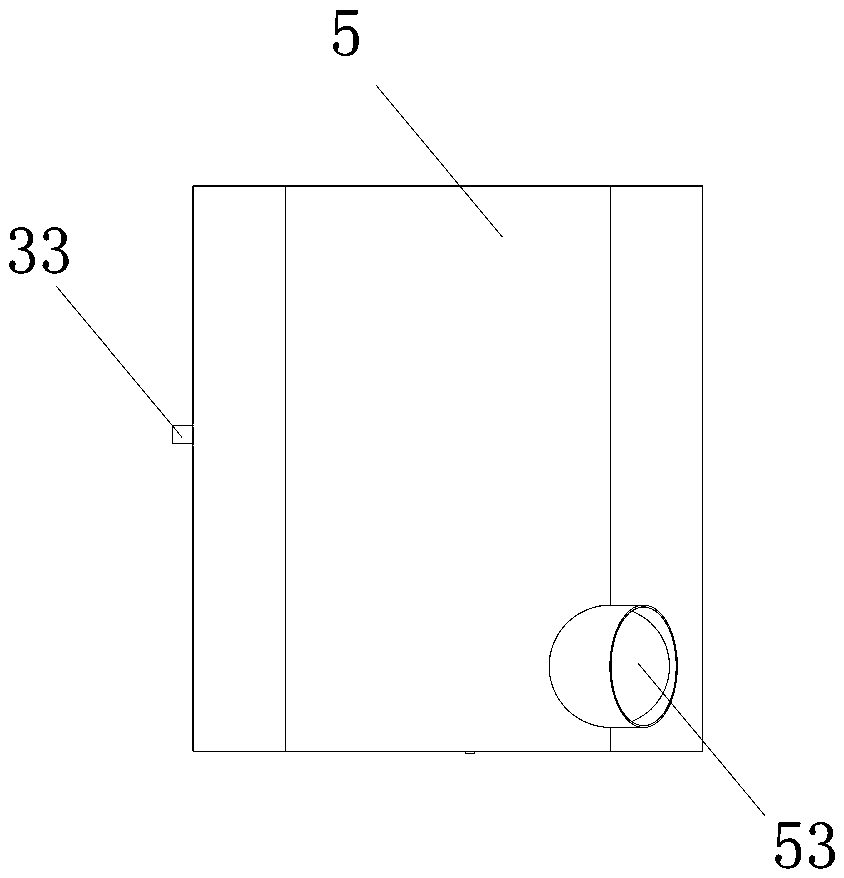

[0035] Such as Figure 1-9 As shown, this embodiment includes a first air intake pipe 11 connected to the engine 1 and a first air outlet pipe 12, a muffler housing 5, a hydrogen fuel oil tank 6, an accelerator sensor 7 installed on the accelerator pedal, a controller 8 and a catalytic converter. Device 9. A muffler cavity 51 is opened in the muffler housing 5 , and an exhaust gas inlet 52 and an exhaust gas outlet 53 connected to the muffler cavity 51 are opened on the muffler housing 5 , and the exhaust gas inlet 52 is connected to one end of the first outlet pipe 12 . A support plate 54 located in the middle of the muffler cavity 51 and an evaporator passing through the support plate 54 are disposed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com