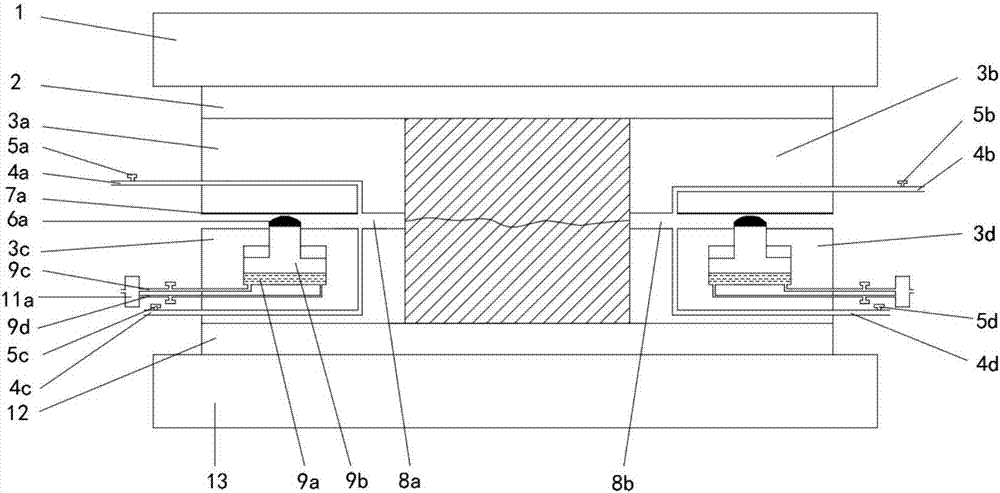

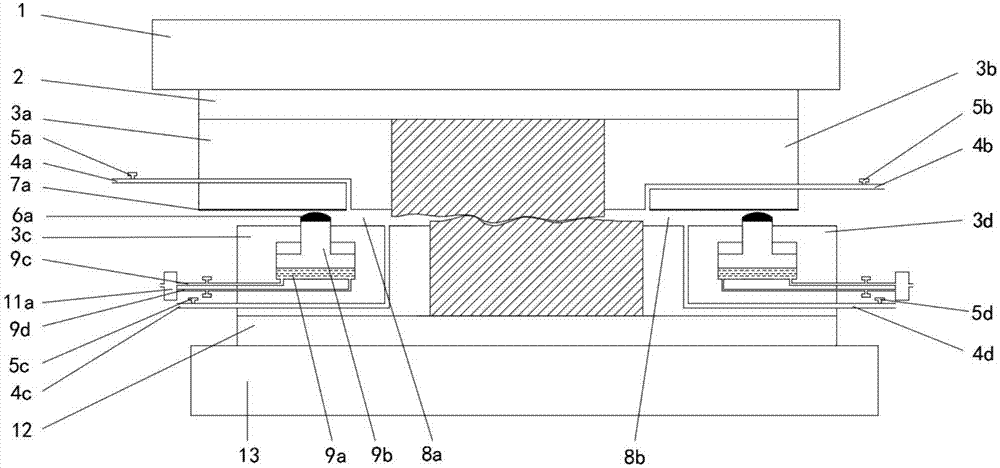

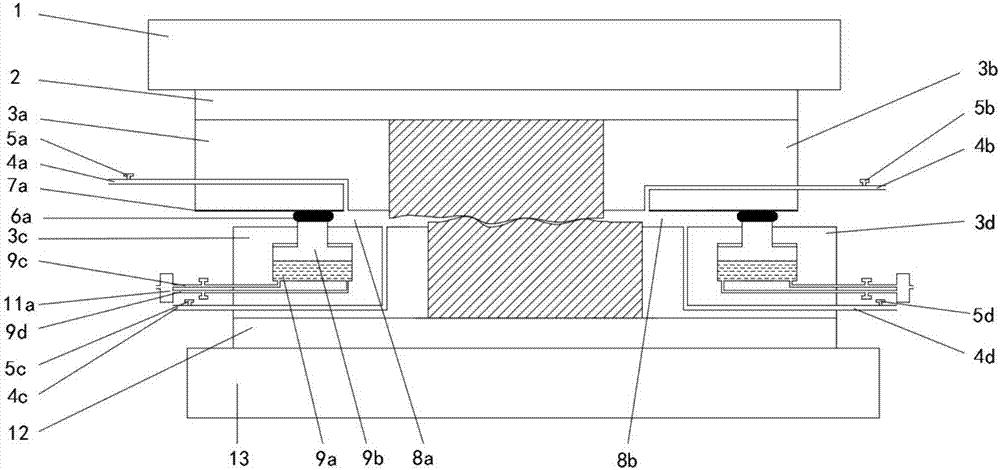

Servo controlled rock fracture shear seepage test sealing device

A technology of rock fissure and sealing device, applied in the field of rock mechanics, can solve the problems of discontinuous shearing process and unstable sealing, and achieve good sealing effect and the effect of continuous shear-seepage test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] Example 1. Precise control of normal stress. The normal jack is equipped with a pressure sensor, and the load applied by the jack can be controlled by the servo during the test. Let σ 1 is the normal stress borne by the specimen, A 1 is the area of the specimen subjected to the normal force; σ 2 is the normal stress applied to the jack, A 2 is the sectional area of the normal jack piston; σ 3 is the stress acting on the piston of the vertical sealing device, A 3 is the cross-sectional area of the piston of the vertical sealing device. Then there is σ 1 A 1 = σ 2 A 2 -σ 3 A 3 . The magnitude of the force acting on the piston in the normal jack and the vertical sealing device can be precisely controlled by the servo controller to ensure that the normal stress acting on the sample remains stable at the set value.

example 2

[0048] Example 2. Treatment of dilation. During the shearing process, the crack will undergo shear expansion, so that the upper and lower parts will gradually open. If a mechanical and fixed sealing device is used, the sealing performance will gradually deteriorate and even water leakage will occur as the cracks open. The servo control system in the present invention can make a comprehensive judgment based on the data of the displacement sensor and the oil pressure data in the vertical sealing device, and automatically compensate the reduction of the oil pressure caused by dilatation to ensure the stability of the seal.

example 3

[0049] Example 3. Variable water pressure test. When performing seepage tests, it is generally necessary to change the water pressure and conduct a series of tests under water pressure. The servo control system in the present invention can monitor the change of water pressure, and automatically adjust the oil pressure in the sealing system, so that the oil pressure is always greater than the water pressure, so as to achieve a good sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com