Tower type crane for teaching and exam training

A tower crane and teaching technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of large energy consumption, high power, and hidden safety hazards, and achieve low overall cost, low cost of moving machines, and safety The effect of reliable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The teaching and training tower crane of the present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the present invention.

[0023] In this specification, unless otherwise specified, "front", "rear", "left", and "right" of the tower crane refer to " Front", "rear", "left", "right", that is, "front" refers to the side the driver is facing.

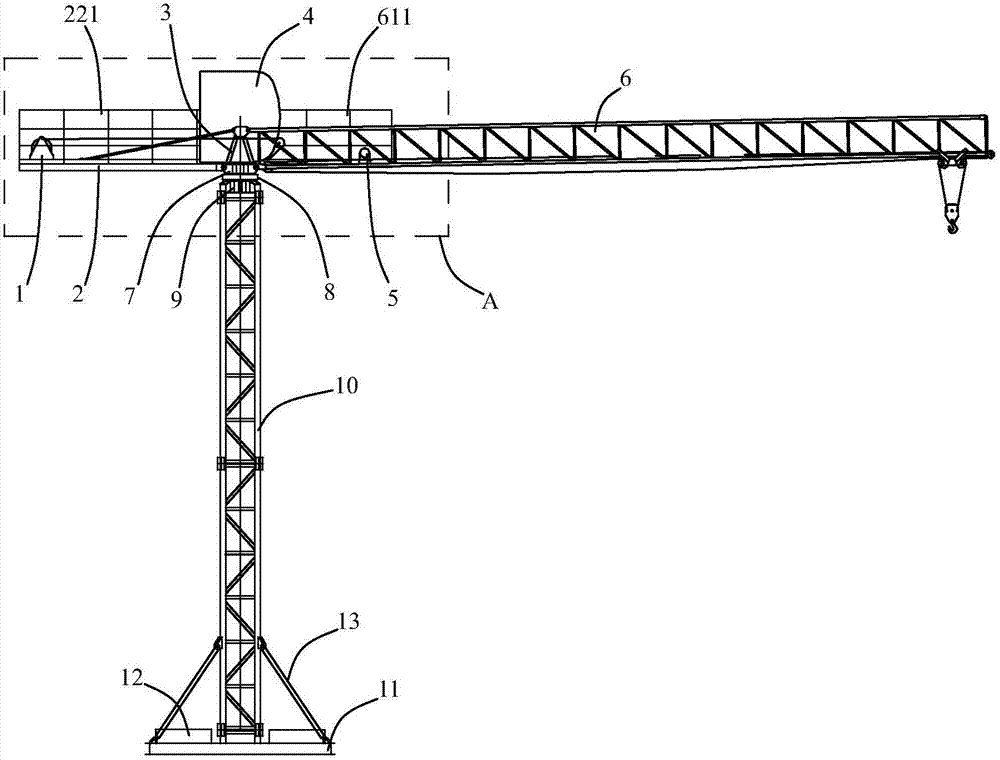

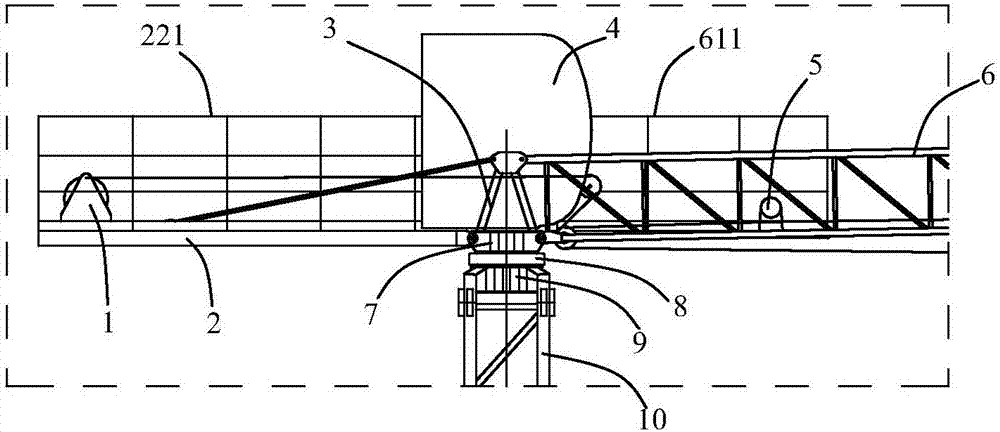

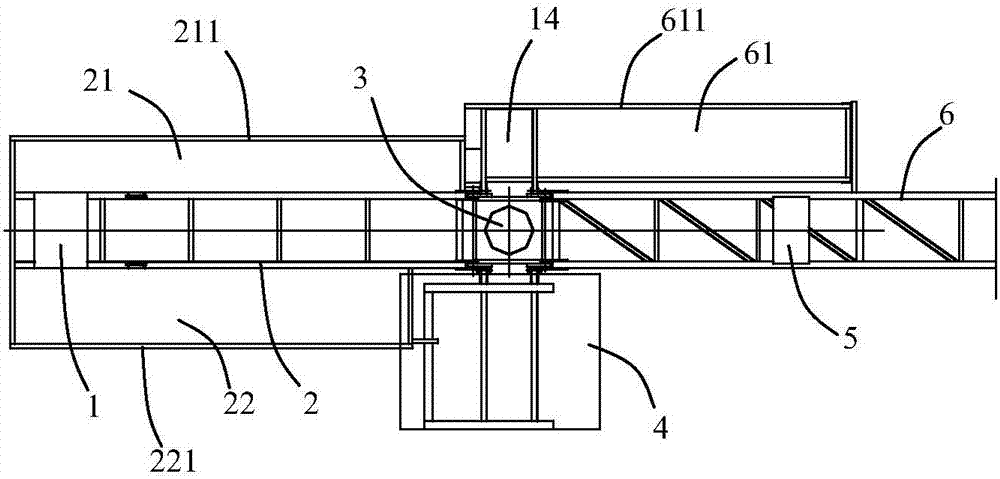

[0024] see Figure 1~3 , The teaching and training tower crane of the present invention includes a balance arm 2, a slewing tower body 3, a driver's cab 4, a boom 6, a tower body 10 and an underframe 11.

[0025] The boom 6 is fixedly installed on the front side of the slewing tower body 3, the balance arm 2 is fixedly installed on the rear side of the slewing tower body 3, and the rear part of the balance arm 2 is provided with a lifting mechanism. 1. The boom 6 is provided with a luffing mechanism 5 . The slewing tower body 3 is a triangular stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com