A split type high voltage series compensation damping mov

A series compensation, split technology, applied in the direction of varistor, overvoltage protection resistor, resistor, etc., can solve the problem of current sharing requirements of resistors, prevent potting glue from seeping glue, seal moisture-proof performance is remarkable, Even distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

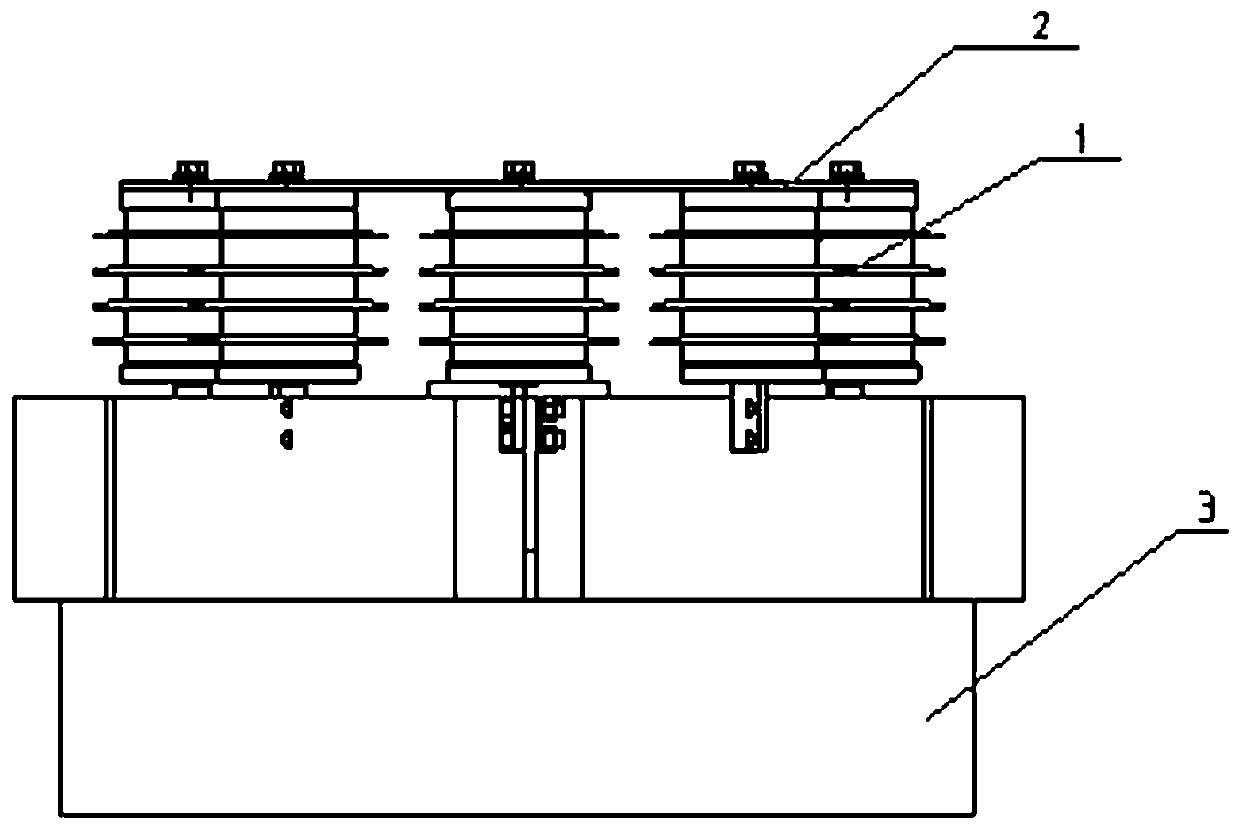

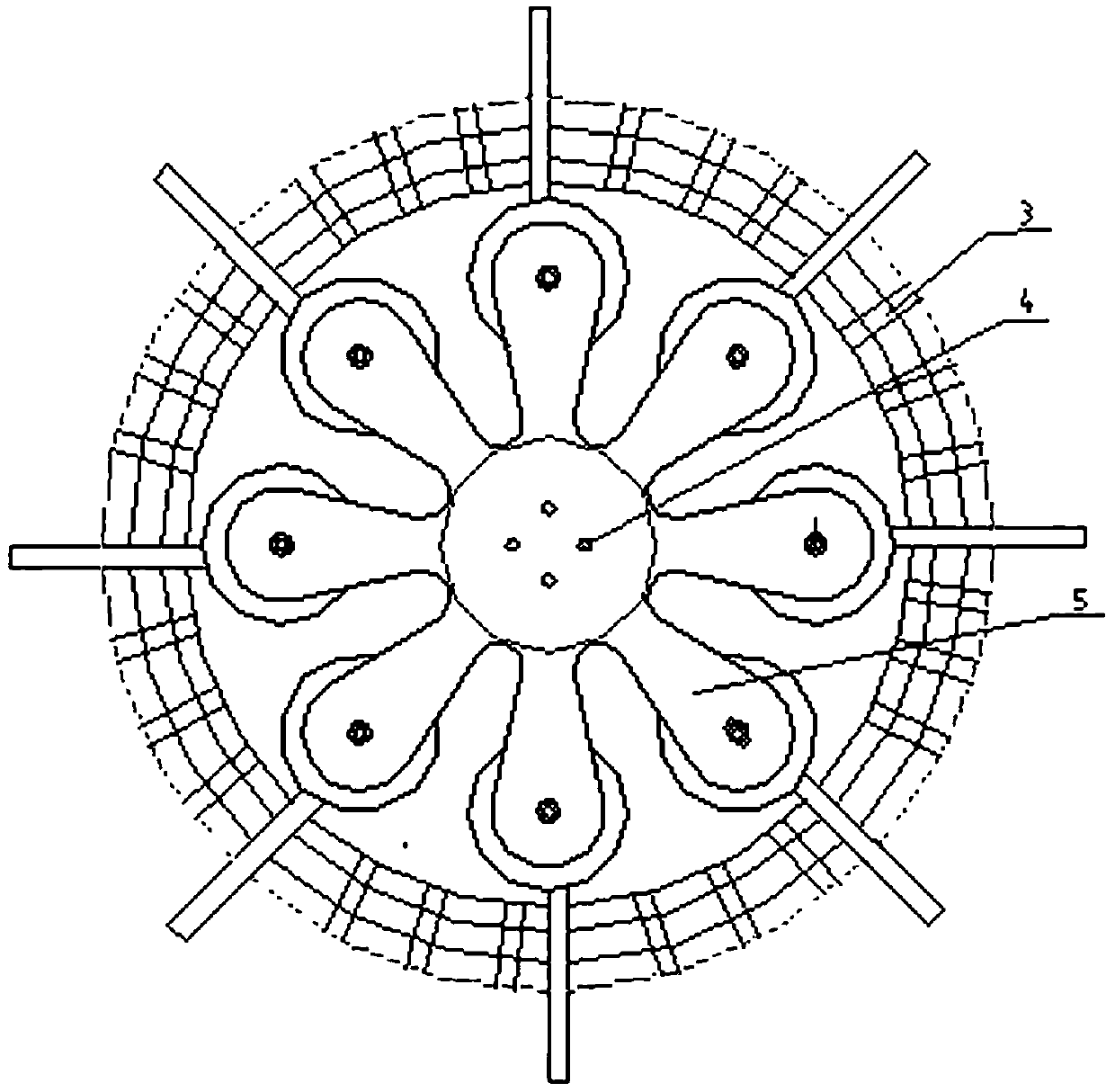

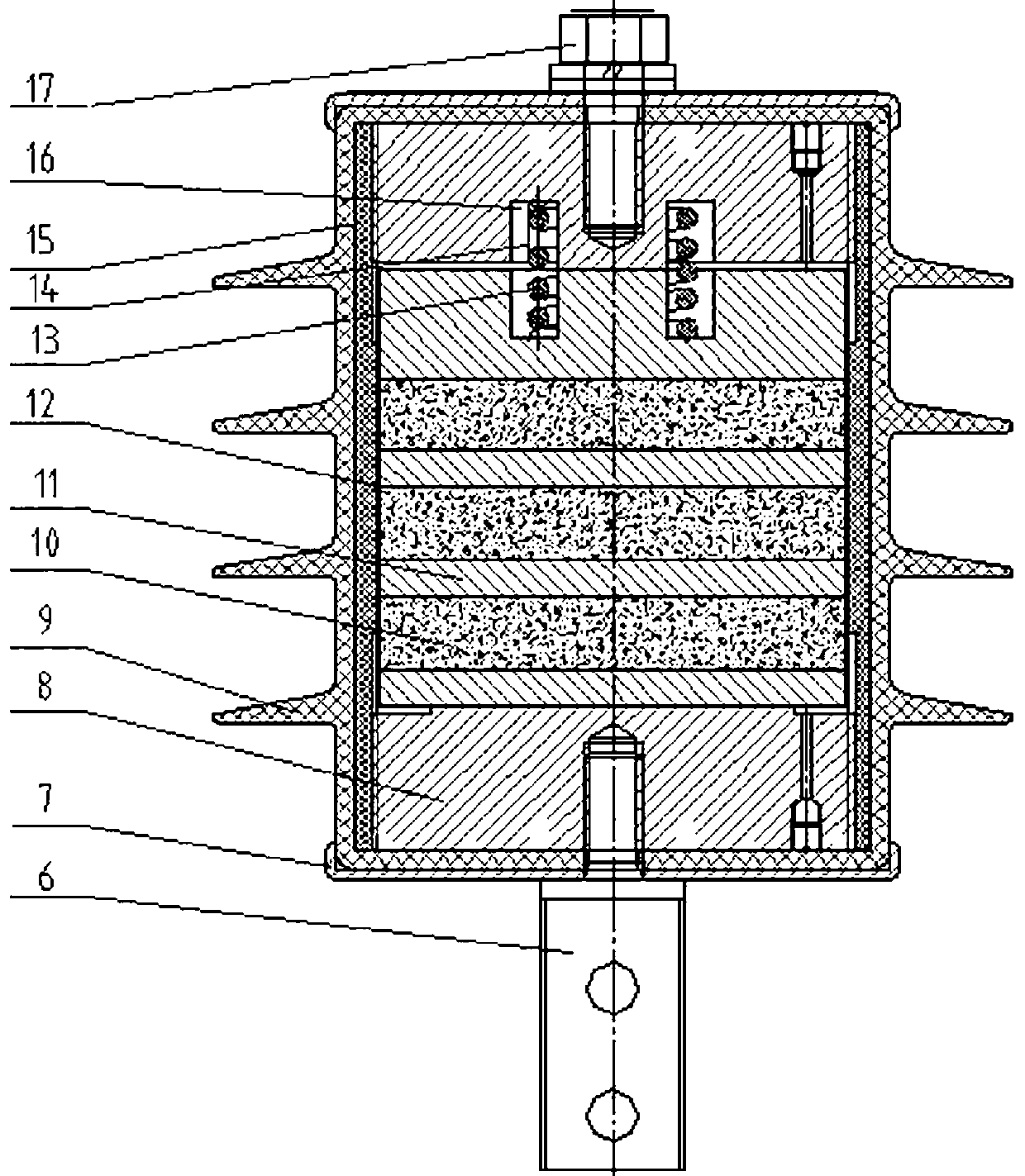

[0022] See attached figure 1 , figure 2 , image 3 It is an embodiment of the present invention.

[0023] A split-type high-voltage series compensation damping MOV, comprising a resistor device 1 and a current sharing connection plate 2, one end of the resistor device 1 is fixedly connected to a reactor 3, and the other end of the resistor device 1 is connected to a current sharing The plate 2 is fixedly connected, and the flow equalizing connecting plate 2 includes a circular plate 4 and a mounting arm 5, the circular plate 4 and the mounting arm 5 are integrally cut and formed, the circular plate 4 has holes, and the mounting arm 5 In a radial layout, each mounting arm 5 is connected with a resistor device 1; the resistor device 1 includes an insulating cylinder 15, a resistor 10, a gasket 11 and a two-component potting silicone rubber 16, the The resistance sheet 10 is wrapped by an anti-seepage adhesive tape 12, the resistance sheet 10 and the gasket 11 are stacked alt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com