GaN HEMTs power device-to-diamond heat sink transfer method

A technology of power device and transfer method, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc. It is difficult to meet the heat dissipation requirements of the device, and achieve the effect of avoiding damage, easy implementation, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

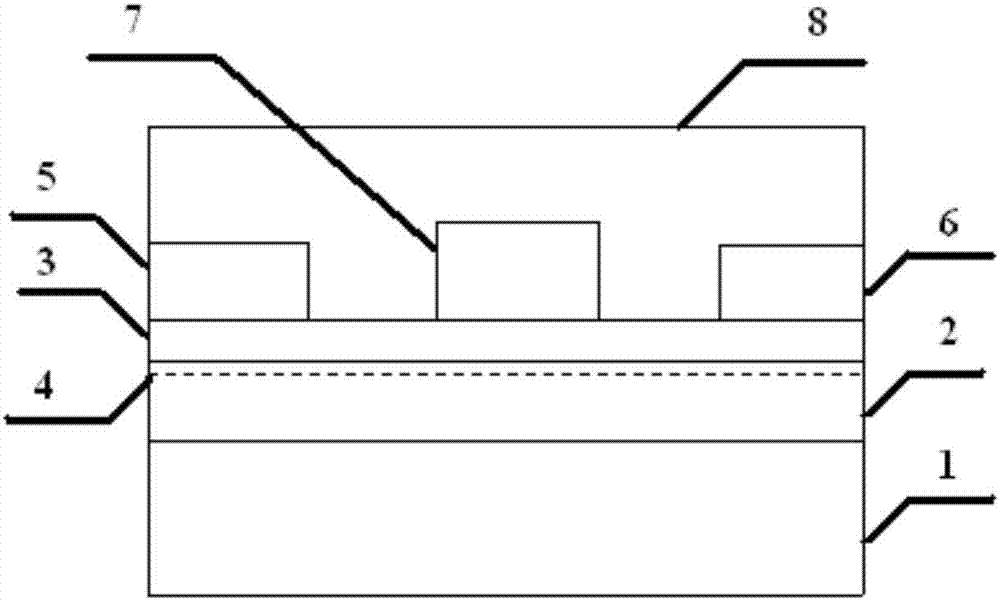

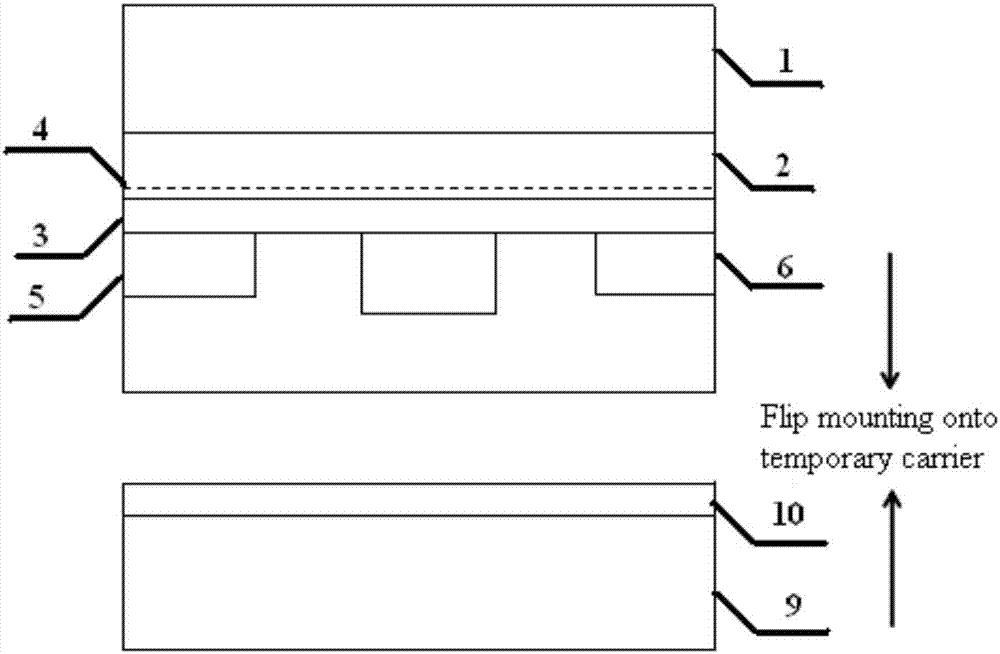

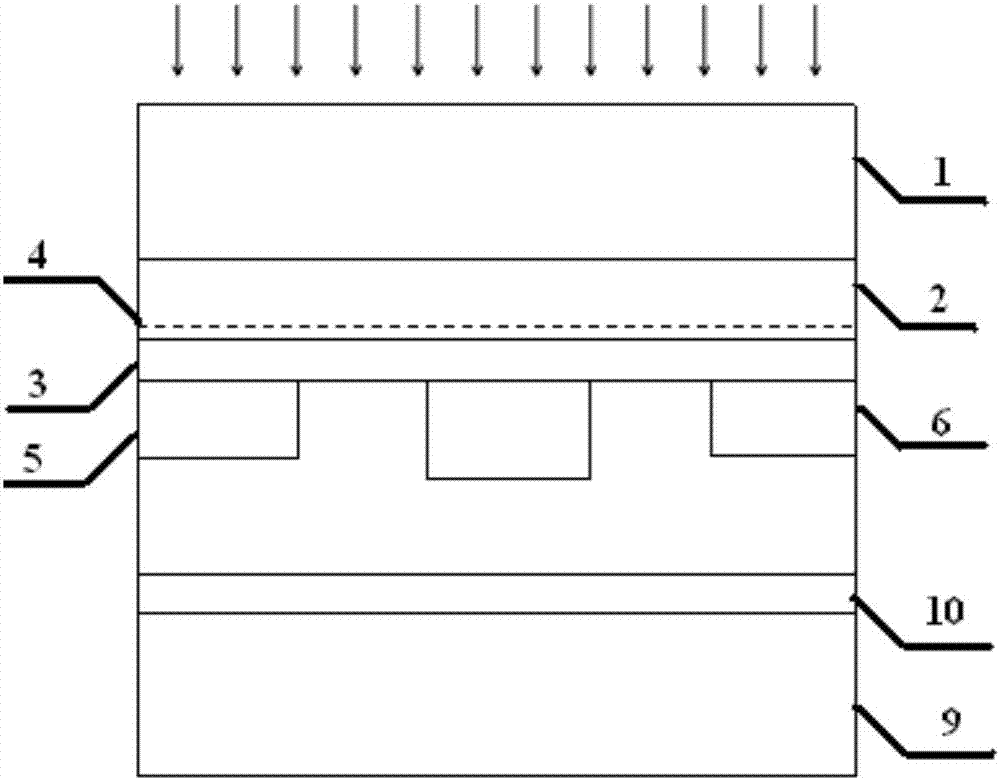

[0045] Such as figure 1 As shown, the sapphire substrate GaN HEMTs power device, the device structure is a common structure, the thickness of the sapphire substrate 1 is 500μm, the thickness of the undoped GaN layer 2 is 3um, the thickness of the AlGaN barrier layer 3 is 20nm, the source electrode 5 and the drain electrode 6 are ohm The contact electrode adopts Ti / Al / Ti / Au (20 / 100 / 40 / 55nm) multi-layer metal structure, the gate 7 is a Schottky contact electrode adopts Ni / Au / (30 / 250nm) two-layer metal structure, the gate The distance between 7 and source 5 is 2.5 μm, the distance between gate 7 and drain 6 is 2.5 μm, the length of gate 7 is 3 μm, and the width of gate 7 is Wg=100 μm;

[0046] Fabrication of GaN HEMTs power devices on sapphire substrates includes the following steps:

[0047] (1), first clean the sapphire substrate 1, use carbon trichloride, tetrachlorethylene, acetone, ethanol, and deionized water to ultrasonicate for 5 minutes each, and then blow dry in nitrog...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap