A kind of ultra-broadband anti-reflection film and preparation method thereof

An anti-reflection coating and ultra-broadband technology, which is applied in nanotechnology, semiconductor devices, electrical components, etc. for materials and surface science, can solve the problems of inconspicuous anti-reflection effect, and achieve good transmittance and good conductivity , the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

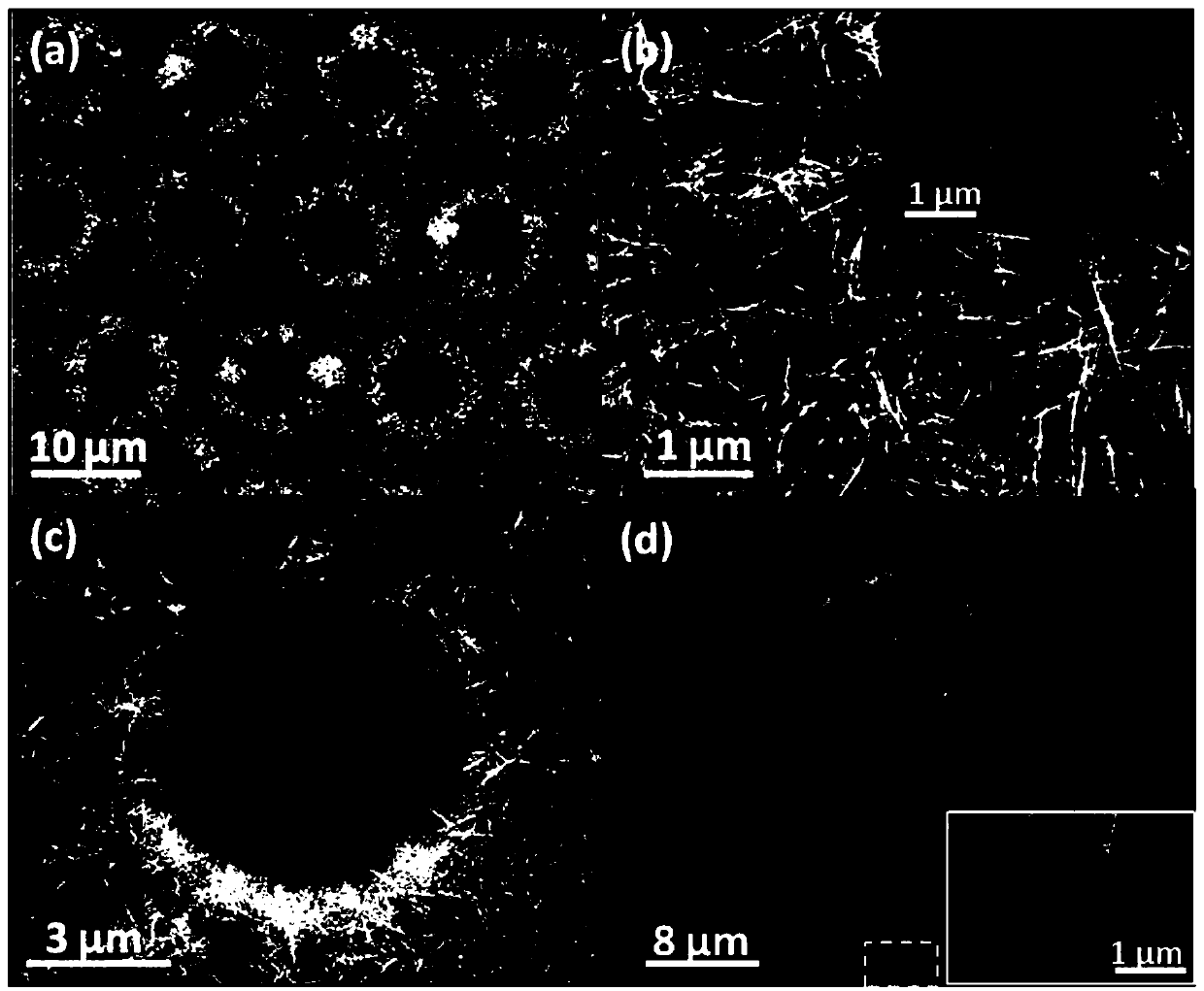

[0035] A method for preparing an ultra-broadband anti-reflection film of the present invention comprises the following steps:

[0036] The first step: cleaning treatment of the substrate.

[0037] 1) Put the substrate material into chloroform and ultrasonically clean it for 10 minutes to remove organic residues on the substrate surface;

[0038] 2) Put the substrate material into deionized water and ultrasonic for about 5 minutes to remove residual chloroform, and then dry it with nitrogen;

[0039] 3) Soak the substrate material in hydrofluoric acid (HF) with a concentration of 10% for 30s, and remove the oxidized part of the substrate surface;

[0040] 4) Put the substrate material into deionized water and ultrasonically clean it for 5 minutes to remove residual HF, and then dry it with nitrogen.

[0041] The second step: preparation of the microwell array.

[0042] 1) Fix the cleaned substrate on a two-dimensional electric translation stage, use a pulsed laser with a wav...

Embodiment 1

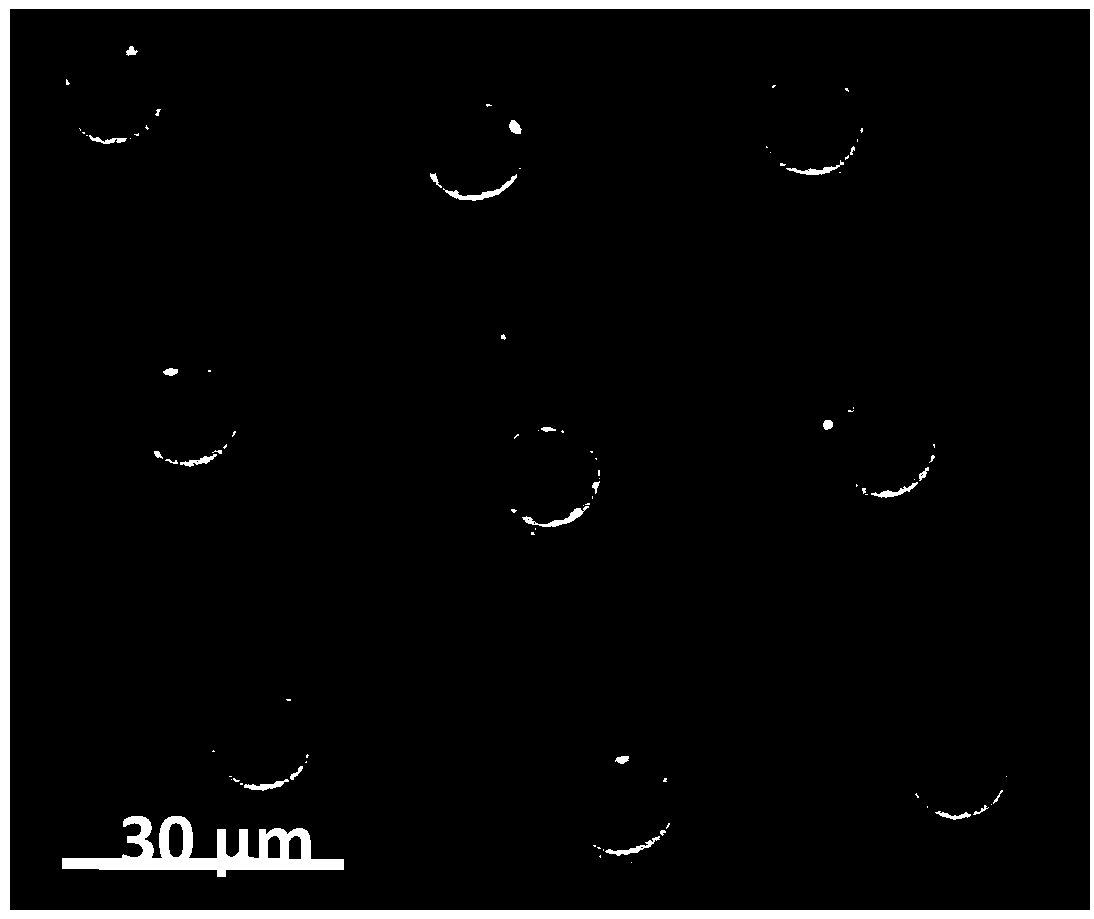

[0054] First utilize the UV spectrophotometer to measure the reflectivity of the cleaned 2-inch Si wafer, the results are as follows image 3 Shown at midline 1.

[0055] Then fix the cleaned 2-inch Si substrate on a two-dimensional electric translation stage, use a pulsed laser with a wavelength of 355nm, a pulse interval of 40ns, and a pulse repetition frequency of 1KHz, and converge the laser spot with a 20x objective lens so that its focus is The surface of the substrate material. Adjust the laser power to 0.08W to perform microhole ablation. After a microhole ablation is completed, move the displacement platform along a fixed direction (x direction) with the distance set at 30 μm, and then perform ablation of the next microhole, and repeat in turn. After the preparation of a row of microholes is completed, adjust the displacement platform in another direction (y direction), and also set the spacing to 30 μm, and repeat the ablation in sequence until the hole spacing of 3...

Embodiment 2

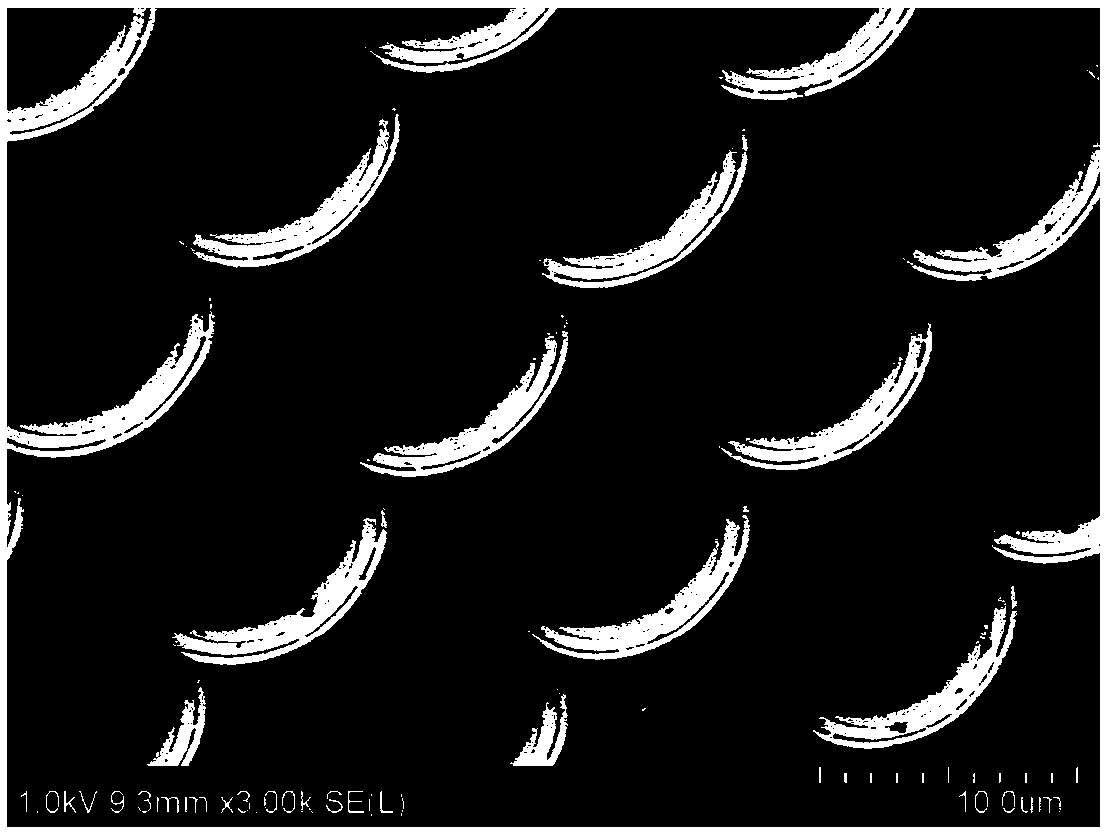

[0058] First utilize the UV spectrophotometer to measure the reflectivity of the cleaned 2-inch Si wafer, the results are as follows Figure 4 Shown at midline 1.

[0059] Then fix the cleaned 2-inch Si substrate on a two-dimensional electric translation stage, use a pulsed laser with a wavelength of 355nm, a pulse interval of 40ns, and a pulse repetition frequency of 1KHz, and converge the laser spot with a 20x objective lens so that its focus is The surface of the substrate material. Adjust the laser power to 0.08W to perform microhole ablation. After a microhole ablation is completed, move the displacement platform along a fixed direction (x direction) with the distance set at 15 μm, and then perform ablation of the next microhole, and repeat in turn. After the preparation of a row of microholes is completed, adjust the displacement platform in another direction (y direction), and also set the spacing to 15 μm, and repeat the ablation in sequence until the hole spacing of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com