Generator, fluid distribution system and heating method of fluid distribution system

A fluid distribution and generator technology, which is applied to liquid injection devices, atomizers for treatment, injection devices, etc., can solve problems such as adverse effects on the human body, excessive power consumption for heating, and unfavorable use of atomizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

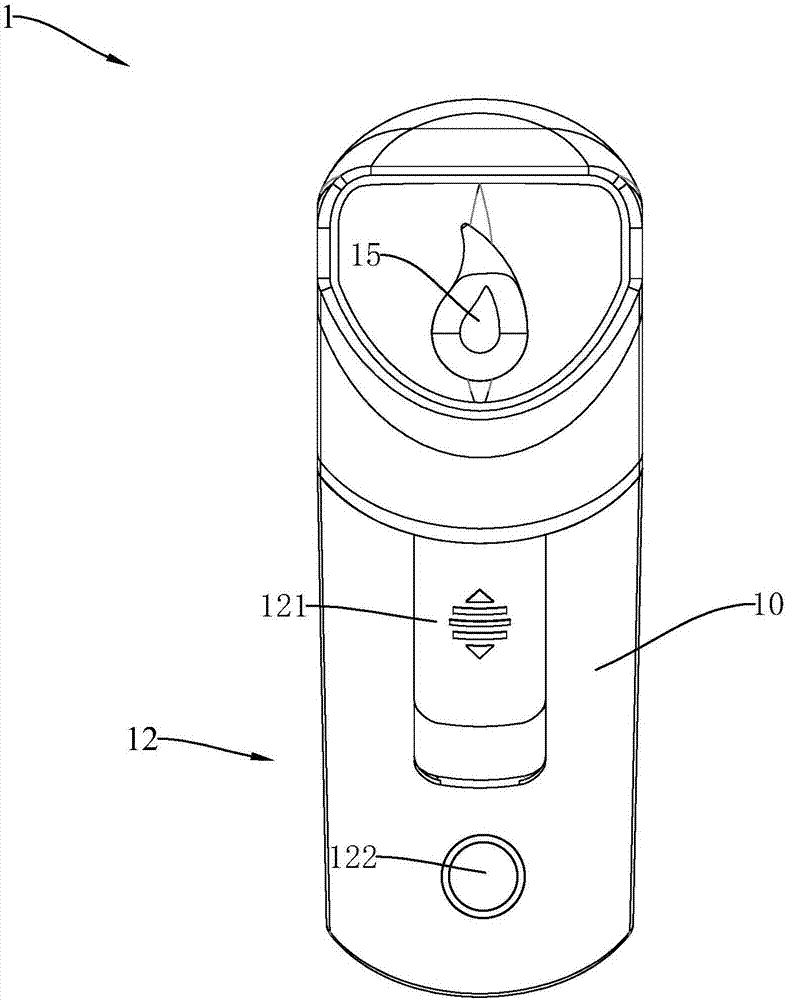

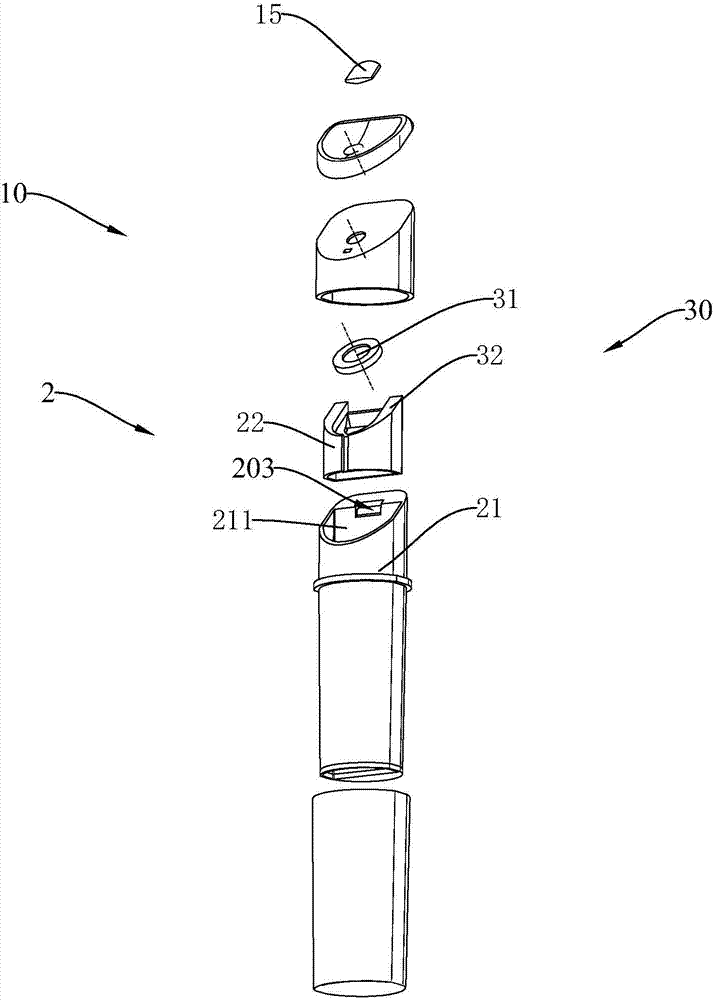

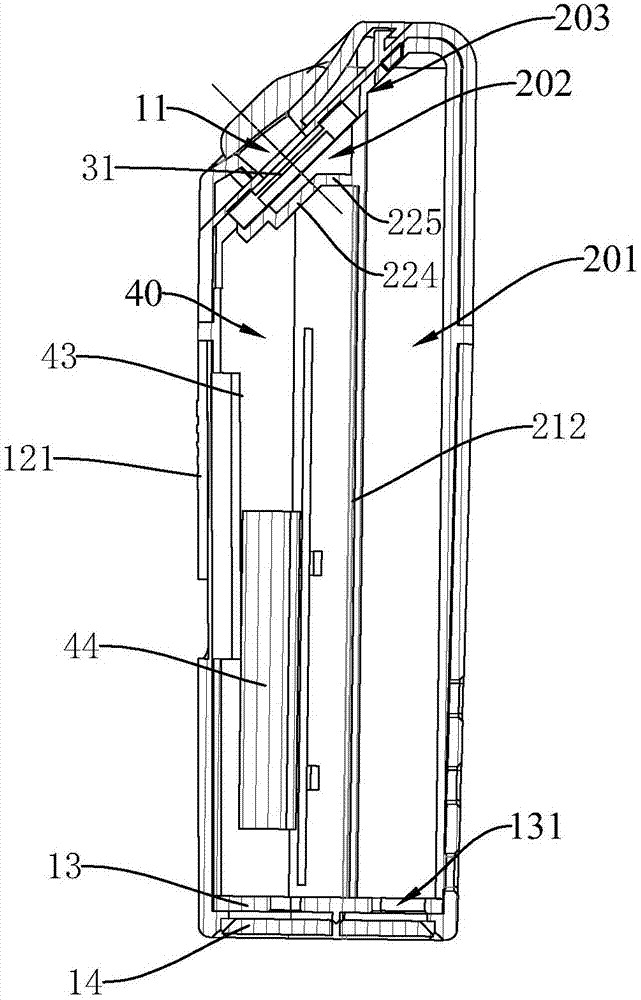

[0065] Figure 1 to Figure 7B The atomizing device 1 shown is suitable for the nose, the spray port 11 is opened on the top of the outer shell 10, and the atomized liquid can be sprayed upwards to reach the nose, and the secondary water chamber 202 is located in the generator. Below the generator 31, the generator 31 is obliquely aligned with the spray port 11 and the auxiliary water chamber 202. When the atomizing device 1 is in an upright state, the liquid level of the auxiliary water chamber 202 is kept at above the center position of the generator 31 .

[0066] The outer casing 10 includes an operation switch 12, a base 13, a bottom cover 14, and a top cover 15, and the top cover 15 is detachably mounted on the spray port 11 to open or close the spray port 11. The operation The switch 12 is installed on the side of the outer casing 10, the operation switch 12 includes a spray switch 121 and a heating switch 122, the spray switch 121 is electrically connected to the atomiz...

Embodiment 2

[0113] Figure 9 to Figure 10 What is shown is another atomizing device 1A, which is suitable for a spray water replenishing instrument, such as spraying and moisturizing the skin. The atomizing device 1A includes an outer shell 10A and is installed in the outer shell 10A. The fluid distribution system 2A, the outer casing 10A includes an upper casing 16A and a lower casing 17A, the upper casing 16A is detachably connected to the lower casing 17A, the outer casing 10A is provided with a spray port 11A, The spray port 11A is opened on the side of the lower housing 17A, the fluid distribution system 2A includes a liquid distribution module 20A, an atomization assembly 30A and a control module 40A, and the liquid distribution module 20A is provided with a main water chamber 201A, The auxiliary water chamber 202A, the water inlet 203A and the partition 212A, the water inlet 203A communicates with the main water chamber 201A and the auxiliary water chamber 202A, and the liquid in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com