Semi-automatic fire fighting truck

A semi-automatic, fire truck technology, applied in fire rescue and other directions, can solve problems such as cost, water loss, insufficient jet power, etc., to ensure transmission stability, easy installation and maintenance, and high use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

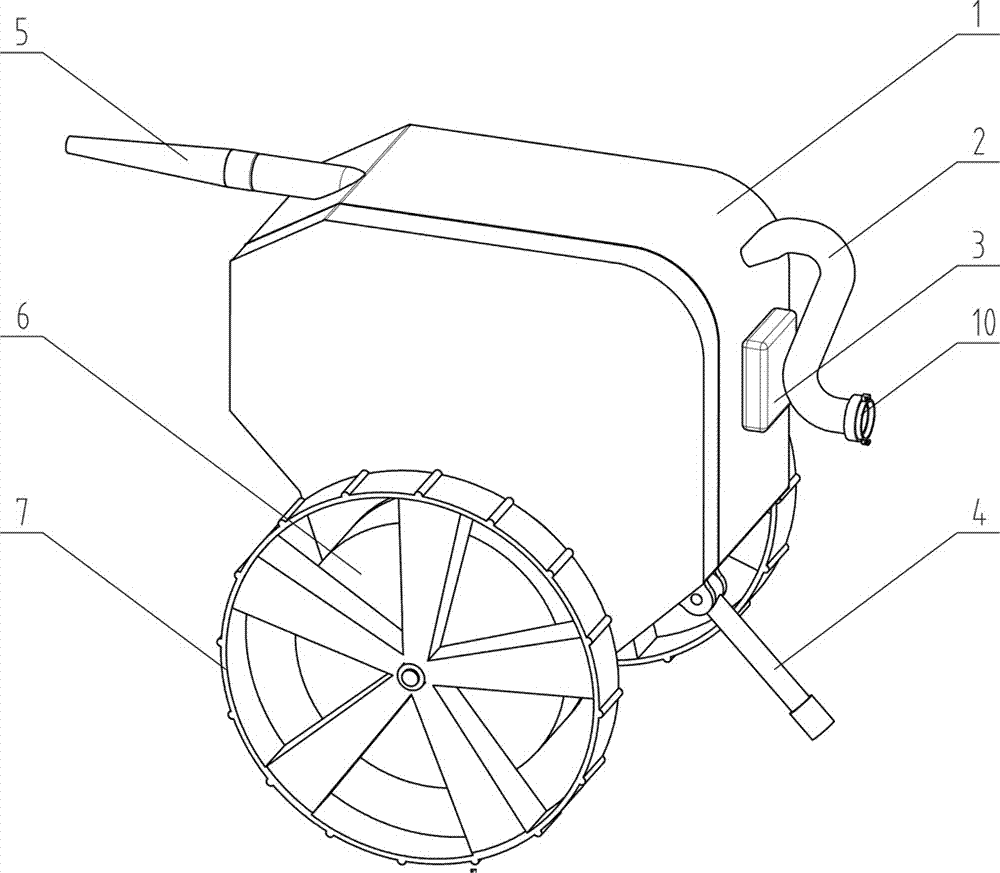

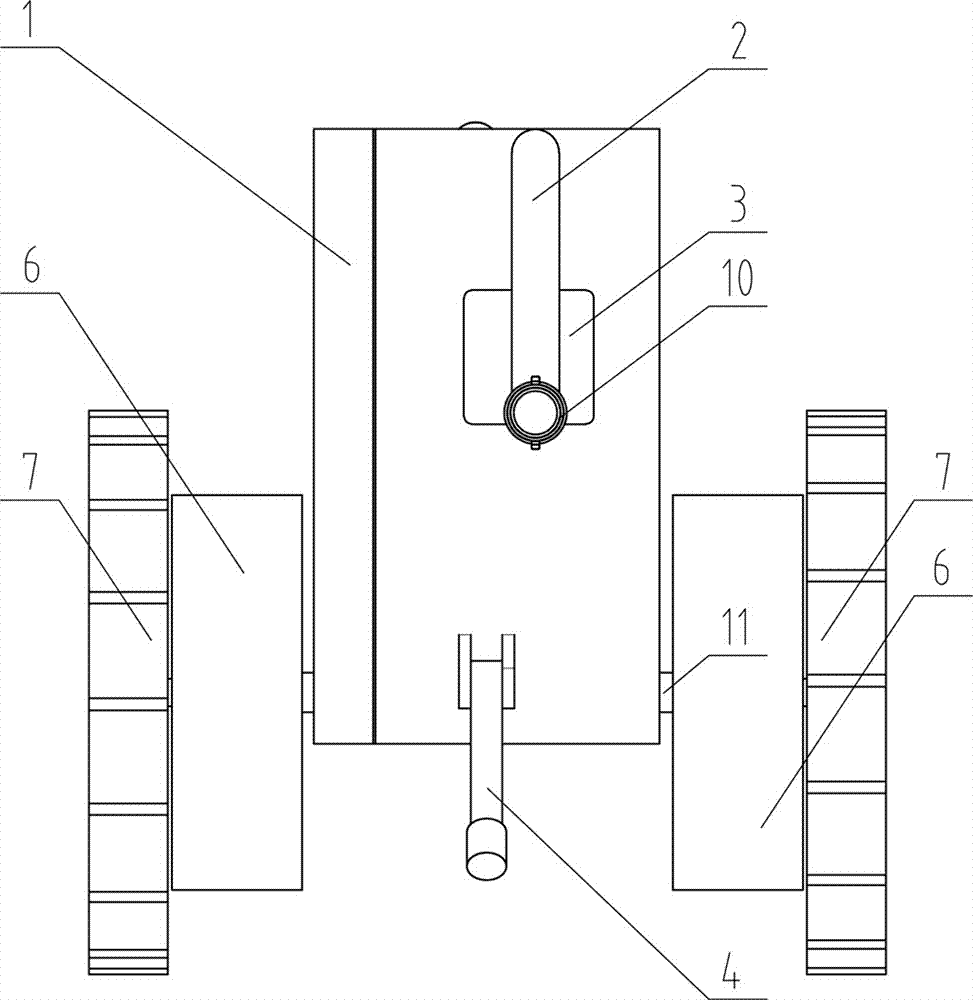

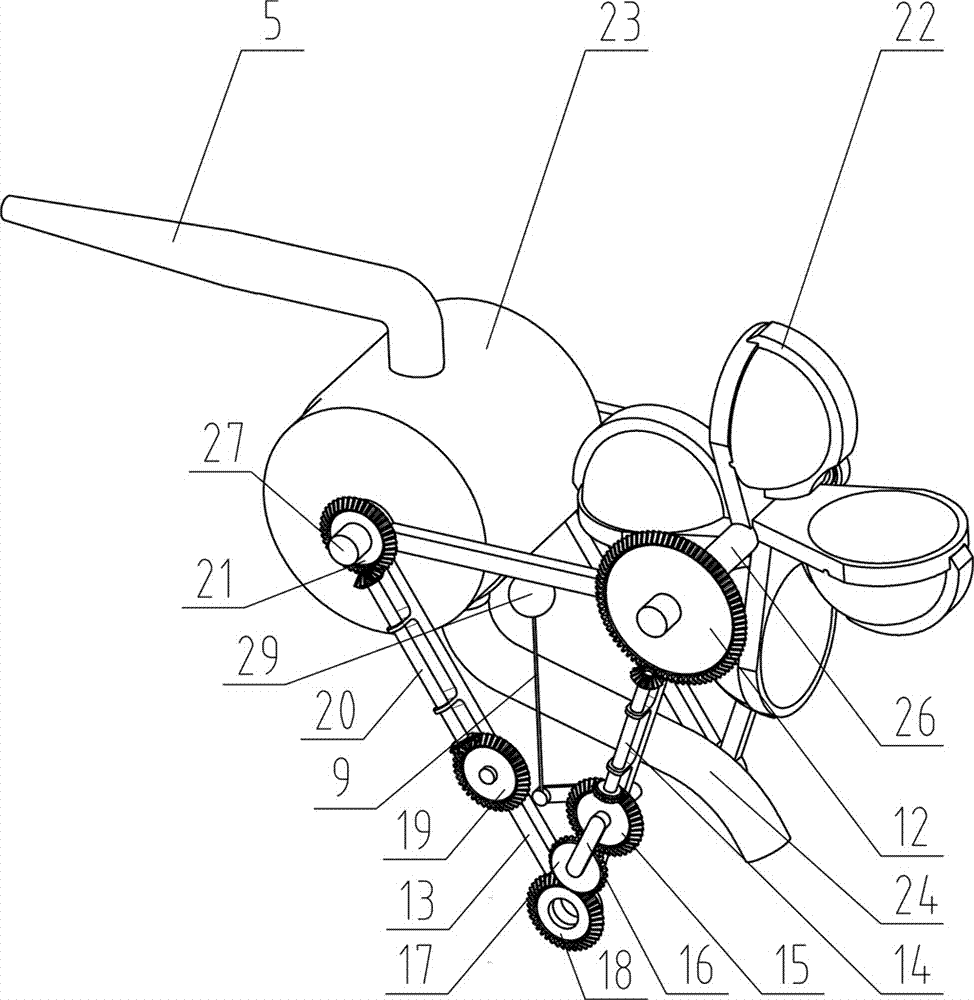

[0030] Such as Figure 1 to Figure 6As shown, a kind of semi-automatic fire fighting vehicle comprises shell 1, clapboard 8, the diversion pipe 2 that is arranged on shell 1 back top, support frame and semi-automatic transmission fire-fighting system, and described clapboard 8, support frame and semi-automatic transmission fire-fighting system are all Arranged in the casing 1, the casing 1 is arranged on the connecting shaft 11, the semi-automatic fire-fighting system is distributed on the second support frame 13, and the semi-automatic transmission fire-fighting system consists of the first gear 12, the first gear shaft 14, the second gear 15, The 3rd gear 17, the 4th gear 18, the 5th gear 19, the 2nd gear shaft 20, the 6th gear 21 and hydraulic turbine form, and described support frame comprises first support frame 25 and seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com