Preparation method and application of a surface organically modified vermiculite composite material

A composite material and vermiculite technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of low selectivity, expensive activated carbon, low regeneration efficiency, etc., and achieve strong heavy metal The effect of ion adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

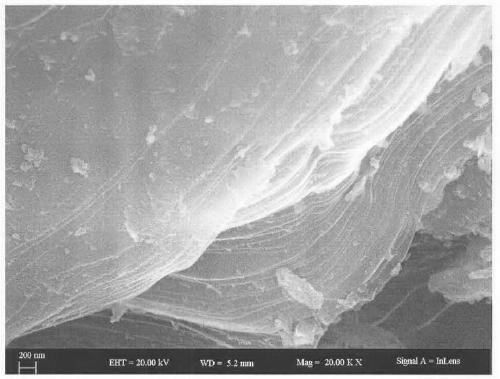

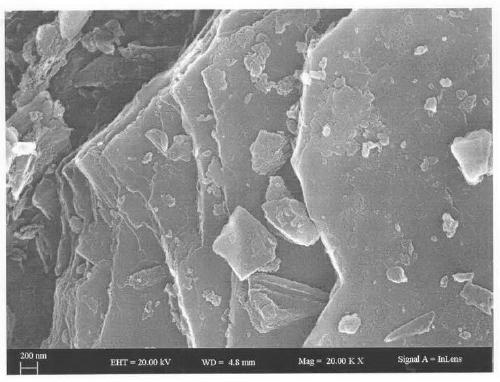

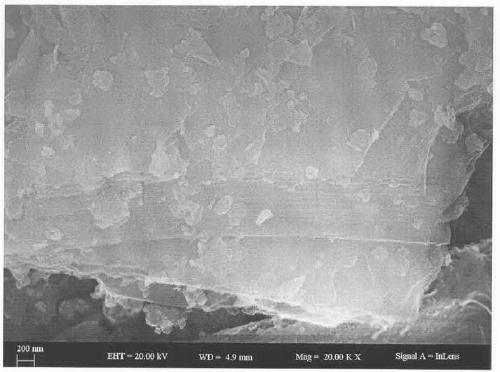

Image

Examples

Embodiment 1

[0028] a. Purification of vermiculite: add vermiculite to tap water and wash 3 times, then wash 3 times with deionized water, put it in an oven and dry it at 110°C for 8 hours, take it out, mechanically crush, grind, and sieve, and take a particle size of 30 The target ore sample is ready for use;

[0029] b. Vermiculite activation: mechanically pulverize and sieve the treated vermiculite in step a, take a 30-mesh ore sample and put it in a 250mL flask, add 1mol / L hydrochloric acid for activation, condense and reflux at a temperature of 50°C for 6h, Centrifuge at 8000 rpm, wash with water until neutral, dry in an oven at 110°C for 8 hours, take it out for later use;

[0030] c, the vermiculite mechanically crushed and sieved after the treatment in the step b, and the ore sample with a particle size of 200 objects is taken for subsequent use;

[0031] d. Preparation of adsorbent: Take 3.00g of acidified vermiculite, 1mL of water, 100mL of toluene and 3mL of 3-triethoxysilyl pr...

Embodiment 2

[0039] a. Purification of vermiculite: add vermiculite to tap water and wash 3 times, then wash 3 times with deionized water, put it in an oven and bake at 110°C for 8 hours, take it out, mechanically crush, grind, and sieve, and take a particle size of 50 The target ore sample is ready for use;

[0040] b. Activation of vermiculite: mechanically pulverize and sieve the vermiculite treated in step a, take a 50-mesh ore sample and put it in a 250mL flask, add 1mol / L hydrochloric acid for activation, condense and reflux at a temperature of 50°C for 6h, Centrifuge at 8000 rpm, wash with water until neutral, dry in an oven at 110°C for 8 hours, take it out for later use;

[0041] c, the vermiculite mechanically crushed and sieved after the treatment in the step b, and the ore sample with a particle size of 200 objects is taken for subsequent use;

[0042] d. Preparation of adsorbent: Take 3.00g of acidified vermiculite, 1mL of water, 100mL of toluene and 3mL of 3-triethoxysilyl p...

Embodiment 3

[0050] a. Purification of vermiculite: add vermiculite to tap water and wash 3 times, then wash 3 times with deionized water, put it in an oven and dry it for 10 hours at a temperature of 110°C, take it out, mechanically crush, grind, and sieve, and take a particle size of 80 The target ore sample is ready for use;

[0051] b. Activation of vermiculite: mechanically pulverize and sieve the vermiculite after treatment in step a, take the ore sample with a particle size of 80 mesh and put it in a 250mL flask, add 2mol / L hydrochloric acid for activation, condense and reflux at a temperature of 50°C for 8h, Centrifuge at 8000 rpm, wash with water until neutral, dry in an oven at 110°C for 8 hours, take it out for later use;

[0052] c, the vermiculite mechanically crushed and sieved after the treatment in the step b, and the ore sample with a particle size of 200 objects is taken for subsequent use;

[0053] d. Preparation of adsorbent: Take 4.00g of acidified vermiculite, 1mL of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com