Electric field structure for improving cooking fume purification efficiency

A technology of oil fume purification and electric field, which is applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems affecting the effect of oil fume removal and the small area of the anode plate, and achieve the effect of enhancing the effect of oil fume removal, increasing the area of the anode, and using space reasonably and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

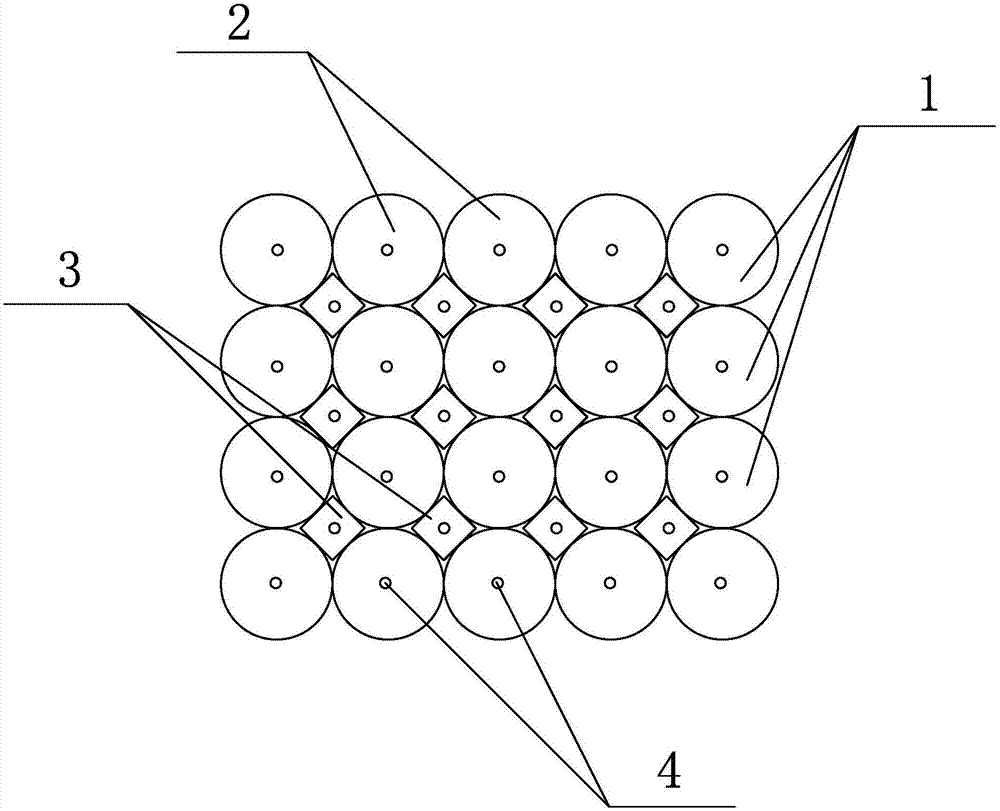

[0022] Such as figure 1 As shown, the electric field structure for improving oil fume purification efficiency in the present invention includes a composite electric field, and the composite electric field includes a plurality of rows of cylindrical smoke removal channel groups 1 sequentially arranged from top to bottom, and the cylindrical smoke removal channel group 1 It includes a plurality of cylindrical anode cylinders 2 arranged horizontally, and gaps are formed between the adjacent four cylindrical anode cylinders 2 in two adjacent rows of cylindrical smoke removal channel groups 1. The gaps are provided with cylindrical The anode cylinder 2 is parallel to the square anode cylinder 3, the four sides of the square anode cylinder 3 are respectively tangent to the sides of the cylindrical anode cylinder 2, and the cylindrical anode cylinder 2 and the square anode cylinder 3 are provided with cathode needles 4, The cathode needle 4 is located at the axis of the cylindrical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com