Preparation method of graphene electrochromic glass

A technology of electrochromic glass and graphene, applied in the direction of coating, etc., can solve the problems of dispersion, fracture, and ITO bending resistance, and achieve the effect of large optical modulation amplitude and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

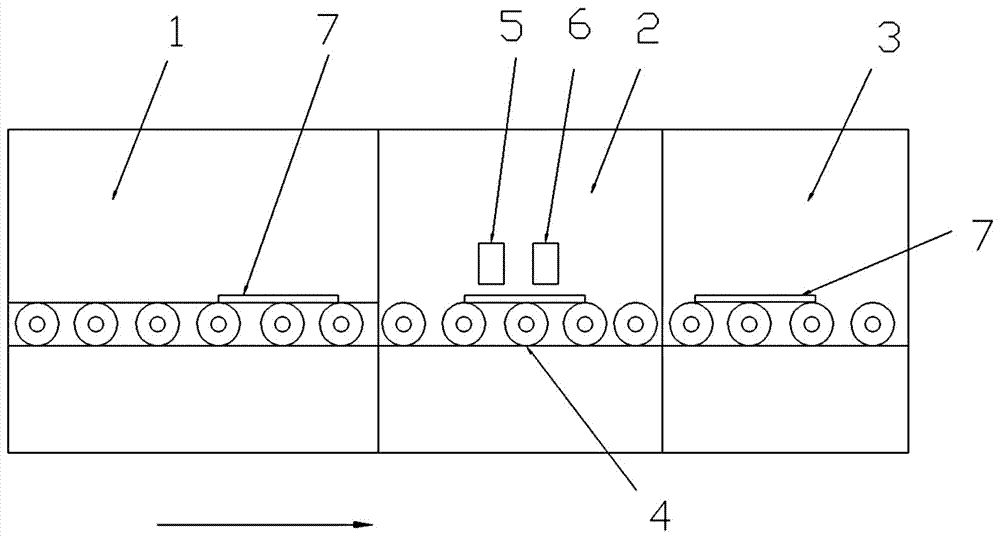

[0020] combine figure 1 and figure 2 Shown, the invention provides a kind of preparation method of graphene electrochromic glass, comprises the following steps:

[0021] a. The heating section 1, the coating section 2 and the annealing section 3 are arranged in sequence along the glass substrate transmission direction; the glass transmission roller table 4 is arranged in the heating section, the coating section and the annealing section; Graphene coating reactor 5 and tungsten oxide coating reactor 6 are installed sequentially in the substrate transport direction; the height from the reactor to the glass substrate is 4mm;

[0022] b. The glass substrate 7 is transferred to the coating section 2 after being heated to a preset temperature of 622°C in the heating section 1; the glass substrate 7 is made of 4mm ultra-clear glass;

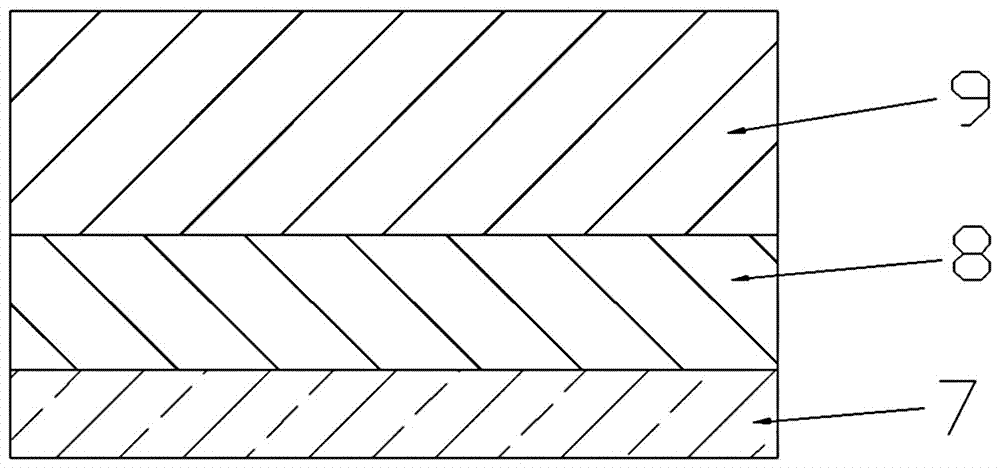

[0023] c, in the coating section 2, the graphene coating reactor 5 first deposits a graphene film 8 on the surface of the passing glass substrate 1,...

Embodiment 2

[0028] combine figure 1 and figure 2 Shown, the invention provides a kind of preparation method of graphene electrochromic glass, comprises the following steps:

[0029] a. The heating section 1, the coating section 2 and the annealing section 3 are arranged in sequence along the glass substrate transmission direction; the glass transmission roller table 4 is arranged in the heating section, the coating section and the annealing section; Graphene coating reactor 5 and tungsten oxide coating reactor 6 are installed sequentially in the substrate transport direction; the height from the reactor to the glass substrate is 6 mm;

[0030] b. The glass substrate 7 is transported to the coating section 2 after being heated to the preset temperature of 1052°C in the heating section 1; the glass substrate 7 is made of 3.2mm ultra-clear glass;

[0031] c. In the coating section 2, the graphene coating reactor 5 first deposits a graphene film 8 on the surface of the passing glass substr...

Embodiment 3

[0036] combine figure 1 and figure 2 Shown, the invention provides a kind of preparation method of graphene electrochromic glass, comprises the following steps:

[0037] a. The heating section 1, the coating section 2 and the annealing section 3 are arranged in sequence along the glass substrate transmission direction; the glass transmission roller table 4 is arranged in the heating section, the coating section and the annealing section; Graphene coating reactor 5 and tungsten oxide coating reactor 6 are installed sequentially in the substrate transport direction; the height from the reactor to the glass substrate is 8mm;

[0038] b. The glass substrate 7 is transferred to the coating section 2 after being heated to a preset temperature of 860°C in the heating section 1; the glass substrate 7 is made of 3.2mm ultra-clear glass;

[0039] c. In the coating section 2, the graphene coating reactor 5 first deposits a graphene film 8 on the surface of the passing glass substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com