Method for controlling edge crack of niobium-containing low-alloy steel produced through CSP (contract strip production) technology

A low-alloy steel and edge cracking technology, applied in the field of metallurgy, can solve the problems of unrealistic fine control of continuous casting secondary cooling nozzles, poor applicability of thin slabs, continuous casting pouring breakouts, etc., and improve the overall process control level , Eliminate the edge crack defects of Nb-containing low-alloy steel, and reduce the effect of steel leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

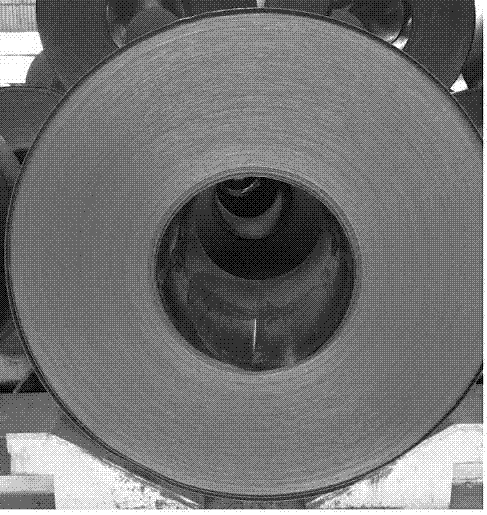

Image

Examples

Embodiment 1

[0032] The present embodiment controls the method for edge cracking of CSP niobium-containing low-alloy steel, and its specific process steps are as follows:

[0033] 1) The chemical composition and mass percentage of molten steel in the continuous casting tundish are controlled as follows: C: 0.04%, Mn: 0.50%, Nb: 0.008%, N: 25ppm;

[0034] 2) Argon gas flow control in the continuous casting tundish: after the long nozzle of the continuous casting tundish is connected with the ladle drain, argon is used to seal the gap between the long nozzle and the ladle drain, and the argon flow rate is 2.0m³ / h;

[0035] 3) Continuous casting tundish covering agent control: start adding covering agent to the tundish when the ladle is pouring for 30 seconds, and the amount of covering agent added is 0.2㎏ / t steel;

[0036] 4) Continuous casting speed control: the steel drawing speed of the continuous casting machine is controlled at 3.95m / min;

[0037] 5) The straightening section uses a "T...

Embodiment 2

[0042] The present embodiment controls the method for edge cracking of CSP niobium-containing low-alloy steel, and its specific process steps are as follows:

[0043] 1) The chemical composition and mass percentage of molten steel in the continuous casting tundish are controlled as follows: C: 0.045%, Mn: 1.0%, Nb: 0.015%, N: 30ppm;

[0044] 2) Argon gas flow control in the continuous casting tundish: after the long nozzle of the continuous casting tundish is connected with the ladle drain, argon is used to seal the gap between the long nozzle and the ladle drain, and the argon flow rate is 2.2m³ / h;

[0045]3) Continuous casting tundish covering agent control: start adding covering agent to the tundish when the ladle is pouring for 60S, and the amount of covering agent added is 0.25kg / t steel;

[0046] 4) Continuous casting speed control: the steel drawing speed of the continuous casting machine is controlled at 4.0m / min;

[0047] 5) The straightening section uses a "T"-shape...

Embodiment 3

[0052] The present embodiment controls the method for edge cracking of CSP niobium-containing low-alloy steel, and its specific process steps are as follows:

[0053] 1) The chemical composition and mass percentage of molten steel in the continuous casting tundish are controlled as follows: C: 0.055%, Mn: 1.2%, Nb: 0.020%, N: 35ppm;

[0054] 2) Argon gas flow control in the continuous casting tundish: after the long nozzle of the continuous casting tundish is connected with the ladle drain, argon is used to seal the gap between the long nozzle and the ladle drain, and the argon flow rate is 2.8m³ / h;

[0055] 3) Continuous casting tundish covering agent control: start adding covering agent to the tundish when the ladle is pouring for 120S, and the amount of covering agent added is 0.3㎏ / t steel;

[0056] 4) Continuous casting speed control: the steel drawing speed of the continuous casting machine is controlled at 4.1m / min;

[0057] 5) The straightening section uses a "T"-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com