An online non-destructive testing system and method for the quality of metal additive manufacturing components

A metal additive and non-destructive testing technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to comprehensively detect the quality information of formed components, lack of scalability, versatility and universality, and limited online signal acquisition of single detection objects , to achieve the effect of promoting practical application, ensuring high quality and high reliability, and eliminating doubts about quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

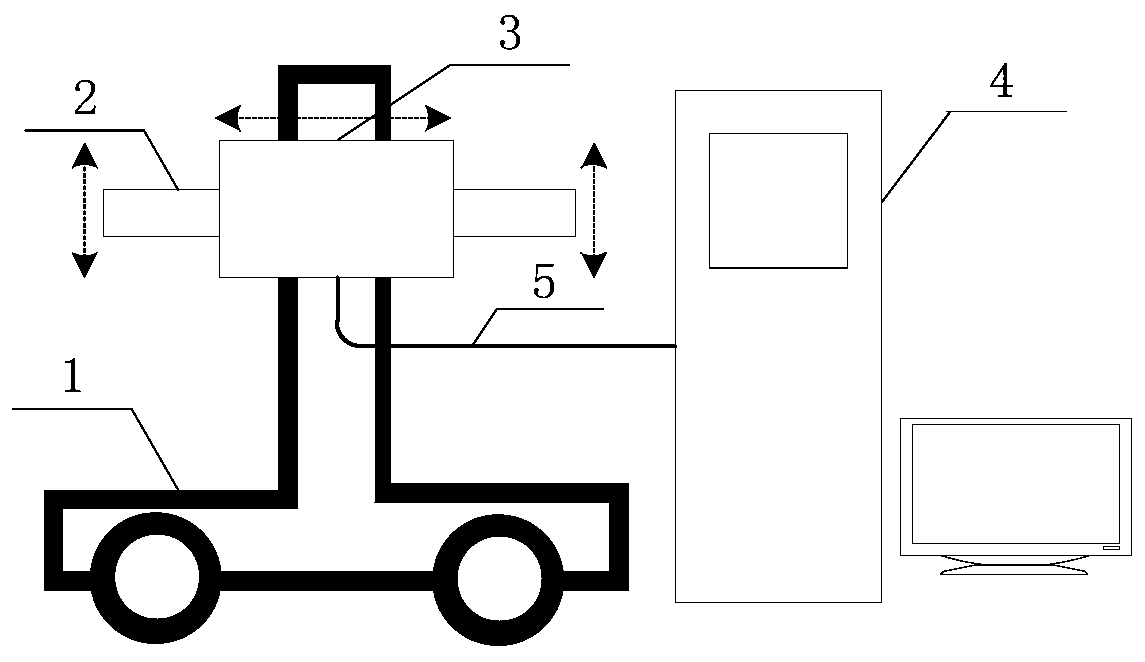

[0066] A system and method suitable for online non-destructive testing of the quality of wire-feeding metal additive manufacturing components, including the following devices and steps.

[0067] Such as Figure 7 As shown, the example of the present invention includes a mobile inspection vehicle 1, a guide rail 2, a control system 4, an optical fiber 5, a mobile probe interface 7, a fixed probe 8, a mobile probe 14, a wire feeding 3D printing head 9, a probe fixture 10, a forming Part 11, energy source 12, substrate 13.

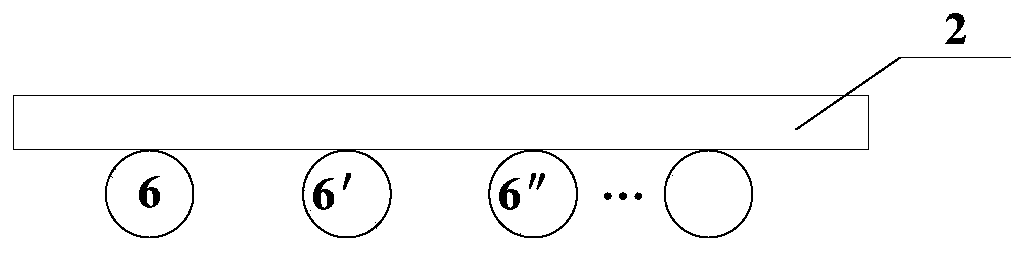

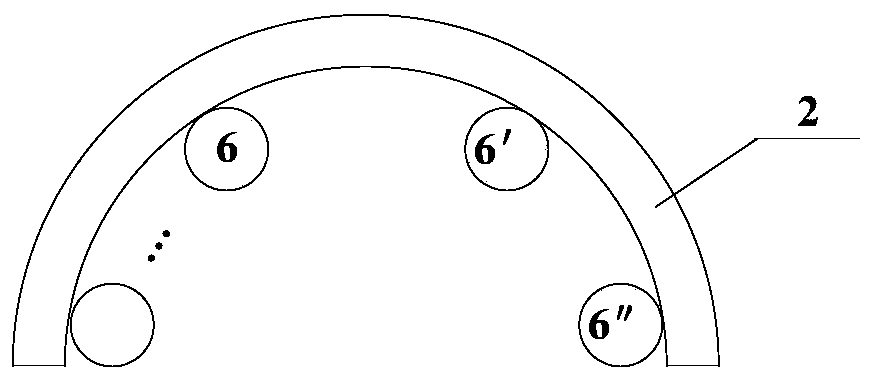

[0068] This example includes two types of fixed probes 8 and movable probes 14 , and the number of the two types of probes is determined according to actual testing needs. The fixed probe 8 moves horizontally or circularly on the guide rail 2, the mobile probe 14 is installed in the mobile probe interface 7, the mobile probe interface 7 moves horizontally or circularly on the guide rail 2, and the guide rail 2 moves vertically on the mobile inspection vehicl...

Embodiment 2

[0079] A system and method suitable for online non-destructive testing of the quality of powder-feeding metal additive manufacturing components, including the following devices and steps.

[0080] Such as Figure 10 As shown, the example of the present invention includes a mobile inspection vehicle 1, a guide rail 2, a control system 4, an optical fiber 5, a mobile probe interface 7, a fixed probe 8, a mobile probe 14, a powder feeding 3D printing head 17, a powder nozzle 16, a forming Part 11, energy source 12 and substrate 13.

[0081] This example includes two types of fixed probes 8 and movable probes 14 , and the number of the two types of probes is determined according to actual testing needs. The fixed probe 8 moves horizontally or circularly on the guide rail 2, the movable probe 14 is installed in the movable probe interface 7, and the movable probe interface 7 moves on the fixed probe 8 and the second fixed probe 8′ or in a circle, and the guide rail 2 is in the Th...

Embodiment 3

[0092] A system and method suitable for online non-destructive testing of the quality of powder-feeding metal additive manufacturing components, including the following devices and steps.

[0093] Such as Figure 12 As shown, the example of the present invention includes a mobile testing vehicle 1, a guide rail 2, a control system 4, an optical fiber 5, a mobile probe interface 7, a mobile probe 14, a powder feeding 3D printing head 17, a powder nozzle 16, a molded part 11, and an energy source 12 and substrate 13.

[0094] In this example, only one type of movable probe 14 is included, and the number of movable probes 14 is determined according to actual detection requirements. The mobile probe 14 is installed in the mobile probe interface 7 , the mobile probe interface 7 moves horizontally or circularly on the guide rail 2 , and the guide rail 2 moves vertically on the mobile inspection vehicle 1 . The powder-feeding 3D printing head 17 is located above the substrate 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com