Oil injection control method, oil injection machine, processor and storage medium

A control method and oil injection machine technology, applied in the field of oil injection machines, processors and storage media, and oil injection control methods, can solve problems such as increased product loss, reduce product loss, improve oil injection accuracy, and solve the problem of increased product loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

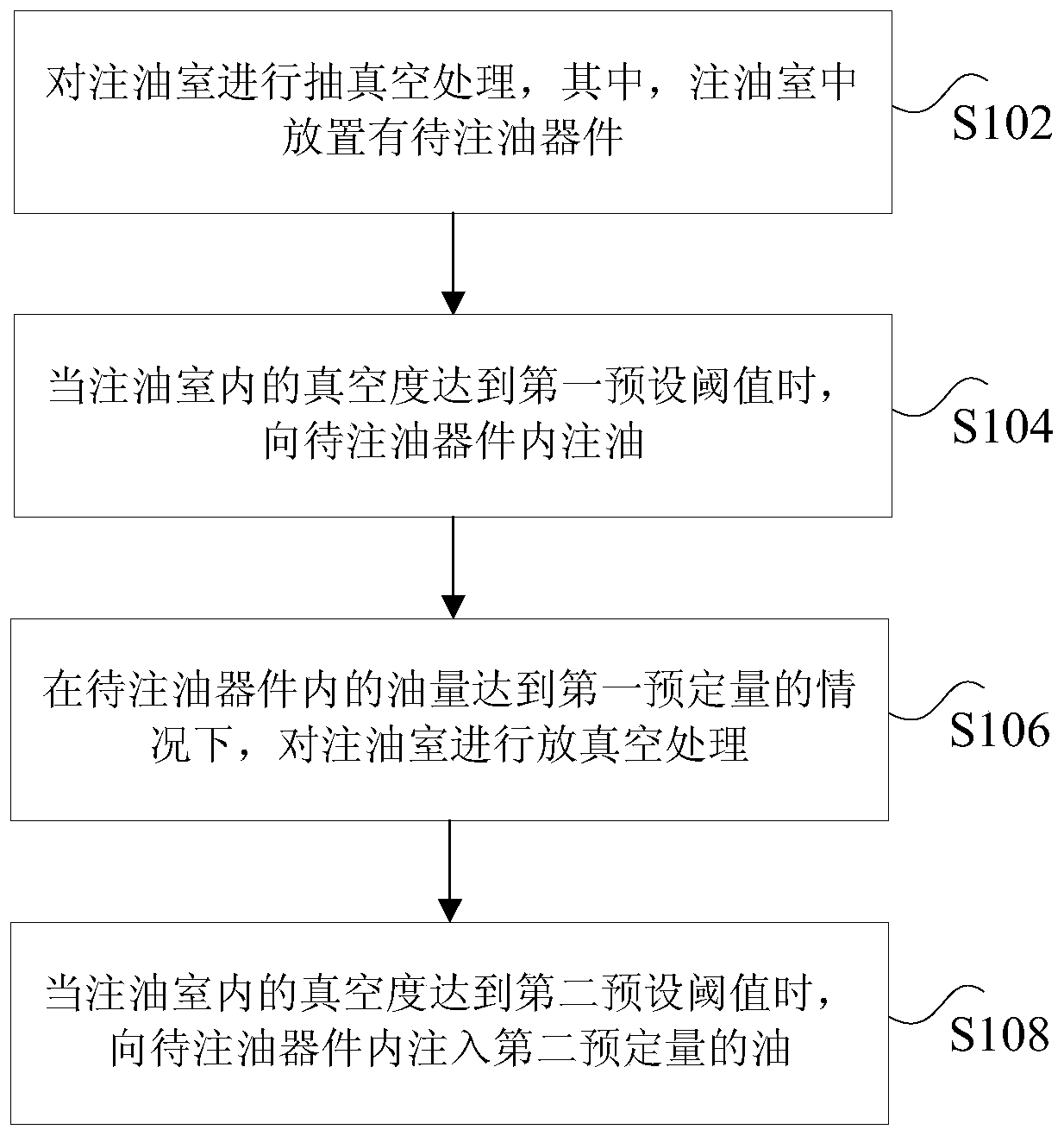

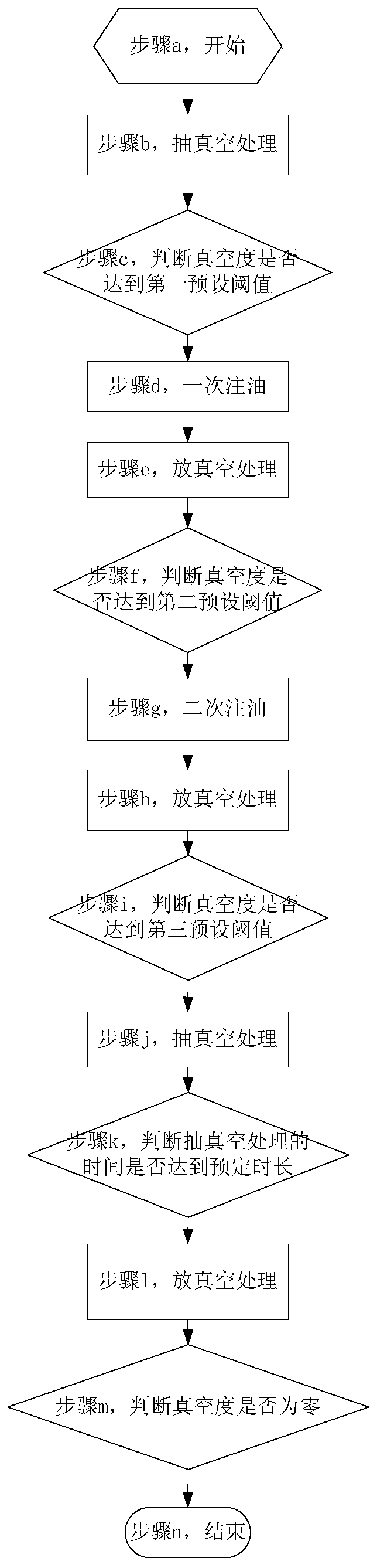

[0034] According to an embodiment of the present invention, a method embodiment of an oil injection control method is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, and, Although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0035] figure 1 is an oil injection control method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0036] Step S102, vacuumize the oil injection chamber, where the components to be oiled are placed in the oil injection chamber.

[0037] In the technical solution provided in step S102 of this application, when the oiling process is performed, the device to be oiled enters the oiling chamber, and the vacuum pump is turned on to va...

Embodiment 2

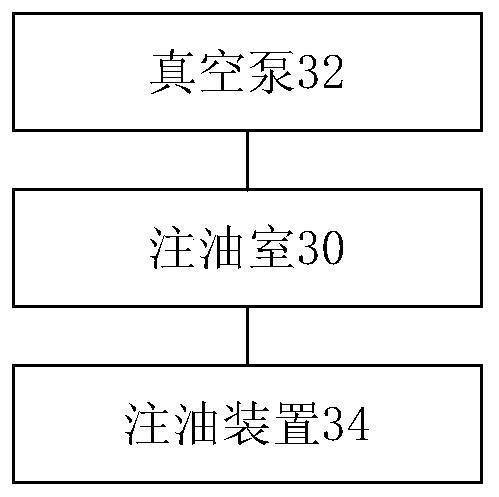

[0103] The embodiment of the invention also provides an oil injection machine. It should be noted that the oil injection machine in this embodiment can be used to implement the oil injection control method in the embodiment of the present invention.

[0104] image 3 is a schematic diagram of an oil injection machine according to an embodiment of the present invention. Such as image 3 As shown, the oiling machine includes: an oiling chamber 30 , a vacuum pump 32 connected to the oiling chamber 30 , and an oiling device 34 connected to the oiling chamber 30 .

[0105] Wherein, the vacuum pump 32 is used for vacuuming the oil injection chamber 30, wherein the oil injection chamber 30 is placed with components to be oiled.

[0106] The oil injection device 34 is configured to inject oil into the device to be oiled when the vacuum degree in the oil injection chamber 30 reaches a first preset threshold.

[0107] The vacuum pump 32 is also used for vacuuming the oil injection c...

Embodiment 3

[0123] An embodiment of the present invention also provides a storage medium, the storage medium includes a stored program, wherein the program executes the oil injection control method with any of the above features.

[0124] The embodiment of the present invention also provides a processor, the processor is used to run a program, wherein, when the program is running, the oil injection control method with any of the above features is executed.

[0125] The serial numbers of the above embodiments of the present invention are for description only, and do not represent the advantages and disadvantages of the embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com