Preparation method of chlorella noodles

A technology for chlorella and noodles, which is applied in the field of food processing, can solve the problems that the taste and nutritional value of noodles cannot meet dietary needs, and achieve a good effect of breaking walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

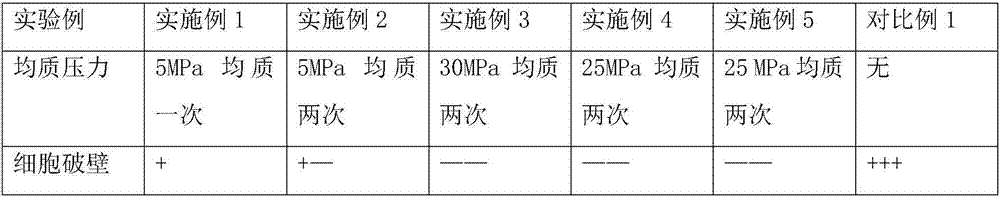

Examples

Embodiment 1

[0025] The present embodiment, the preparation method of chlorella noodles, comprises the following steps:

[0026] First, add distilled water to the chlorella powder and dilute it into chlorella liquid, the mass ratio of chlorella and distilled water is 5:100;

[0027] Second, place the chlorella liquid under a pressure of 5 MPa and homogenize once to obtain a cracking liquid;

[0028] Third, add cellulase and pectinase respectively in the above-mentioned cracking solution, the addition of cellulase and pectinase is 10% of the quality of cracking solution, and the mass ratio of cellulase and pectinase is 3: 7. Adjust the pH to 8, enzymatically hydrolyze for 2 hours, and obtain the enzymatic hydrolyzate;

[0029] Fourth, add diatomite to the above-mentioned enzymolysis solution, the amount of diatomite added is 0.5% of the mass of the enzymolysis solution, and take the supernatant after standing for 24 hours;

[0030] Fifth, take 5 parts of the supernatant liquid, 80 parts o...

Embodiment 2

[0033] The present embodiment, the preparation method of chlorella noodles, comprises the following steps:

[0034] First, add distilled water to the chlorella powder to dilute it into chlorella liquid, the mass ratio of chlorella and distilled water is 10:100;

[0035] Second, place the chlorella liquid under 5MPa pressure and homogenize twice to obtain the cracking liquid;

[0036] Third, add cellulase and pectinase respectively in the above-mentioned cracking solution, the addition of cellulase and pectinase is 10% of the quality of cracking solution, and the mass ratio of cellulase and pectinase is 3: 7. Adjust the pH to 8, enzymatically hydrolyze for 2 hours, and obtain the enzymatic hydrolyzate;

[0037] Fourth, add diatomite to the above-mentioned enzymolysis solution, the amount of diatomite added is 0.5% of the mass of the enzymolysis solution, and take the supernatant after standing for 24 hours;

[0038] Fifth, take 10 parts of supernatant liquid, 80 parts of whea...

Embodiment 3

[0041] The present embodiment, the preparation method of chlorella noodles, comprises the following steps:

[0042] First, add distilled water to the chlorella powder to dilute it into chlorella liquid, the mass ratio of chlorella and distilled water is 10:100;

[0043] Second, place the chlorella liquid under 30MPa pressure and homogenize twice to obtain the cracking liquid;

[0044] Third, add cellulase and pectinase respectively in the above cracking solution, the addition of cellulase and pectinase is 20% of the quality of the cracking solution, and the mass ratio of cellulase and pectinase is 3: 7. Adjust the pH to 8, enzymatically hydrolyze for 2 hours, and obtain the enzymatic hydrolyzate;

[0045] Fourth, add diatomite to the above-mentioned enzymolysis solution, the amount of diatomite added is 1% of the mass of the enzymolysis solution, and take the supernatant after standing for 24 hours;

[0046] Fifth, take 5 parts of supernatant liquid, 70 parts of wheat flour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com