Handheld electric glue gun for building operations

A building construction, electric technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of daily production trouble, inconvenient operation, uneven glue output, etc., to reduce labor intensity and use cost, change laborious Time-consuming and universally effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

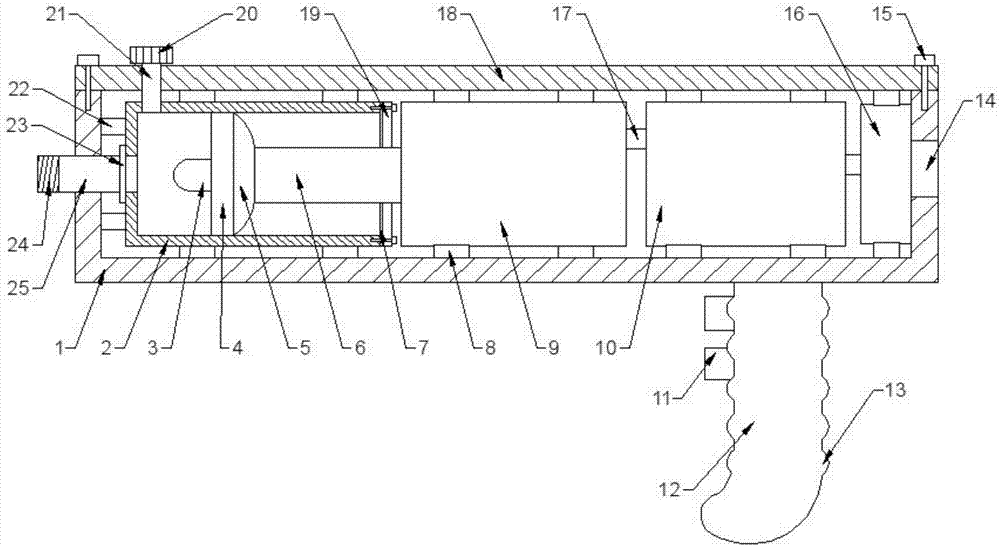

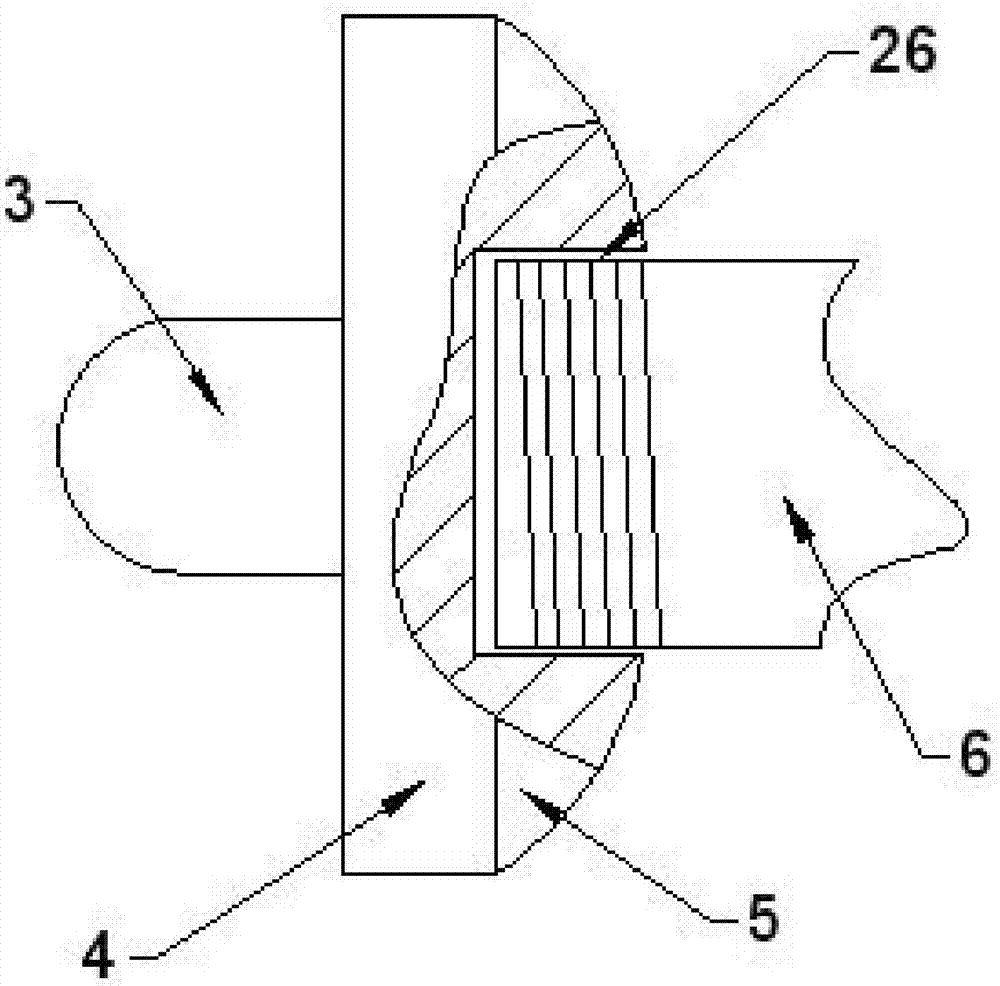

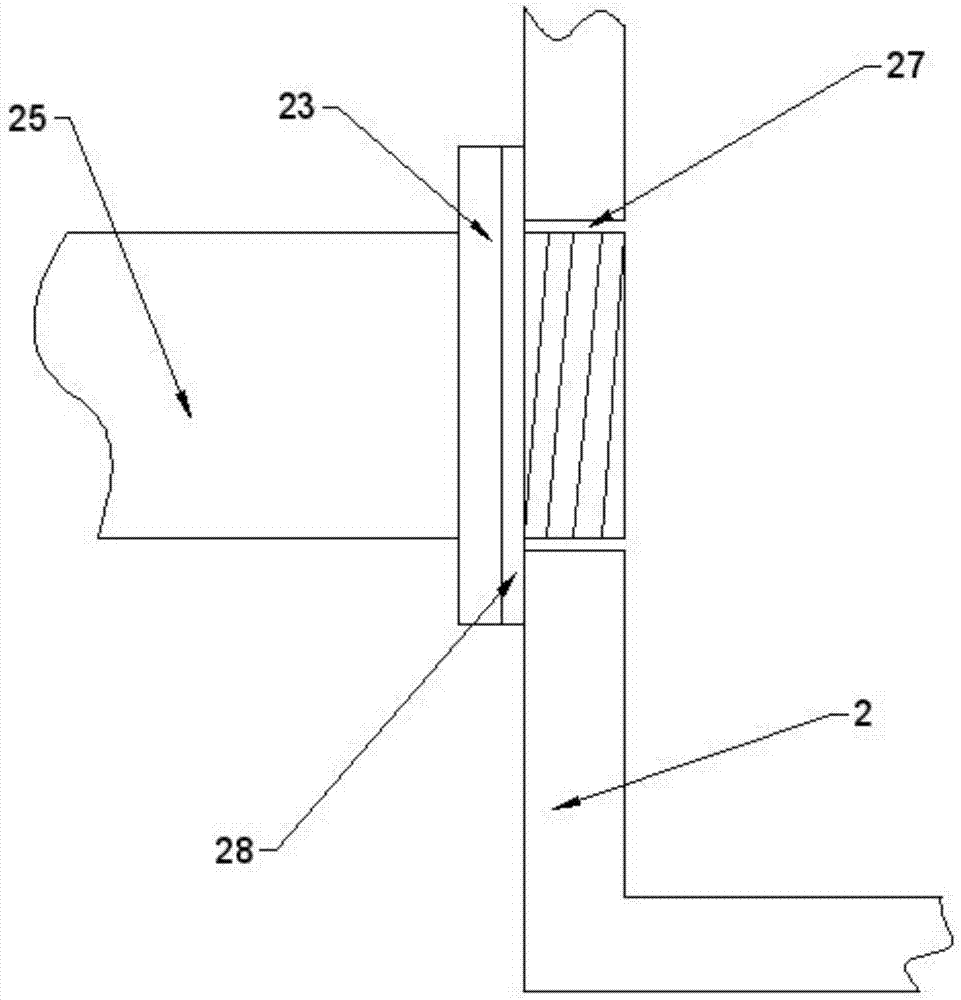

[0021] see Figure 1-4 , a hand-held electric glue gun for building construction, including a casing 1 and a rubber outlet pipe 25; a handle 12 is fixed on the lower surface of the right end of the casing 1; the lower end of the handle 12 is curved, and a plurality of anti-skid protrusions are arranged on the surface 13, it is convenient for the user to hold the device without slipping; the upper left side of the handle 12 is provided with a pressure switch 11; the pressure switch 11 is electrically connected with the control circuit board 16 inside the casing 1 for controlling The operation of the device; the control circuit board 16 is fixed on the right end inside the casing 1 through the fixing card 8, and the right side is electrically connected to the charging port 14, and the left side is electrically connected to the battery 10 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com