Online bus bar automatic welding machine and bus bar automatic welding method

An automatic welding machine and automatic welding technology, applied in welding equipment, soldering irons, auxiliary devices, etc., can solve the problems of slow cooling speed, connection damage, reducing bus bar welding efficiency, etc., and achieve the effect of speeding up efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific embodiment:

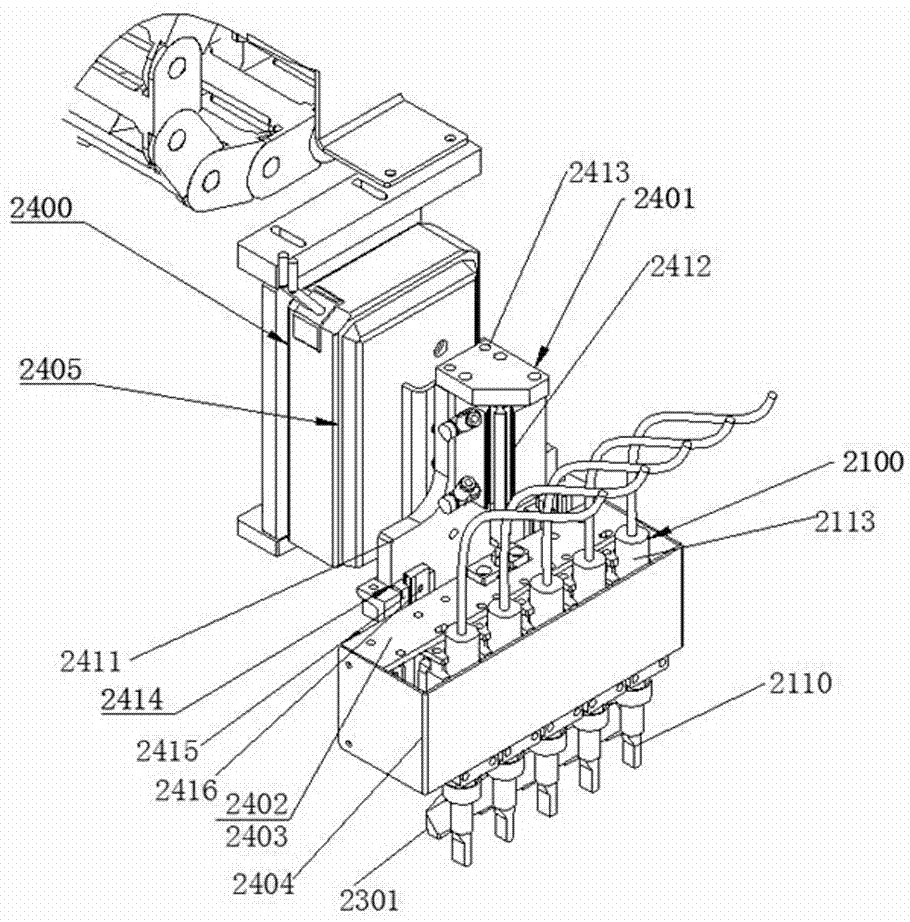

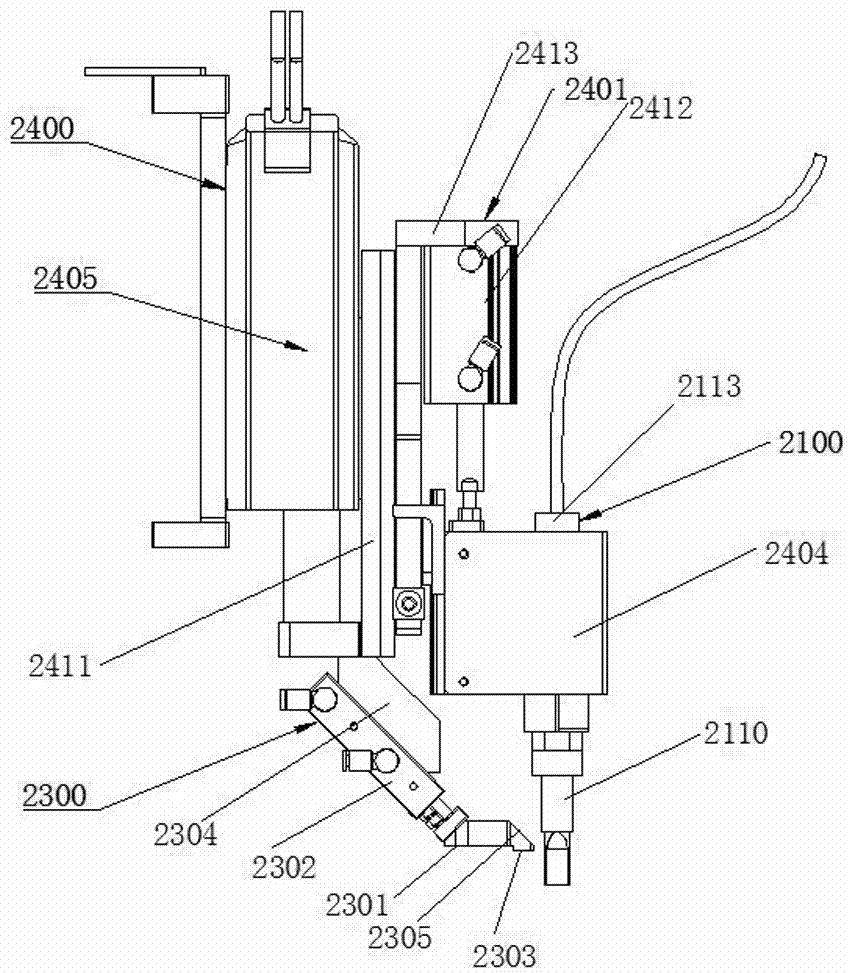

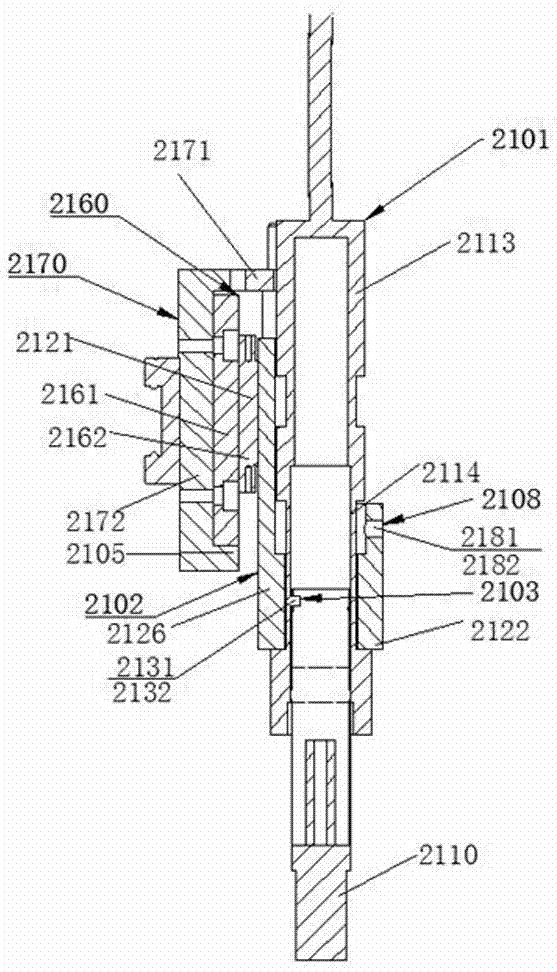

[0040] Such as Figure 1 to Figure 5 As shown, the online bus bar automatic welding machine includes a welding device 2100 and a cooling device 2300. The welding device 2100 is used to heat and weld the bus bar, and the cooling device 2300 cools the welding part of the bus bar. Preferably, the bus bar automatic welding machine also includes a longitudinal displacement device 2400, the longitudinal displacement device 2400 is used to drive the welding device 2100 and the cooling device 2300 close to or away from the bus bar, and the longitudinal displacement device 2400 drives the cooling device 2300 or the welding device 2100 is cooled or welded close to the bus bar. Preferably, the automatic bus bar welding machine also includes a soldering iron mounting base 2403 and a soldering iron mounting plate 2402. A plurality of welding devices 2100 are arranged along the length dir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap