High-strength unmanned aerial vehicle wings, wing processing system and wing processing method

A processing system and processing method technology, applied in the directions of wings, unmanned aerial vehicles, motor vehicles, etc., can solve the problems of easy fading and breaking of wings, and achieve the improvement of impact resistance, prolong service life, and improve toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

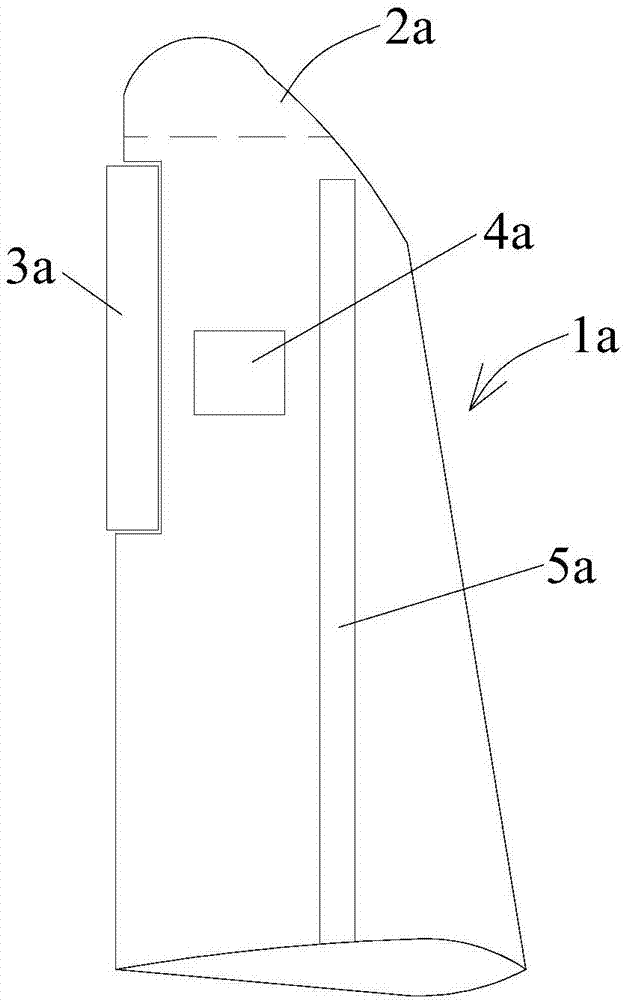

[0043] figure 1 A schematic diagram of the structure of the wing is shown.

[0044] Such as figure 1 As shown, Embodiment 1 provides a wing 1a, and the wing 1a is suitable for being made of a polypropylene microporous foam sheet.

[0045] Further, the wingtip 2a of the wing 1a is bent upwards, and a flap installation position is provided on the outer wing of the wing 1a. When the flap 3a is installed in the flap installation position, it is controlled by the steering gear, and the The bottom surface of the wing is provided with a steering gear placement groove 4a.

[0046] And the bottom surface of the wing is also provided with a reinforcing rib insertion groove 5a, and the reinforcing rib insertion groove can also be used as a wiring groove simultaneously.

[0047] After the wing is made of polypropylene microcellular foamed sheet, it has the advantages of lightness and toughness made of polypropylene microcellular foamed sheet, and makes the wing resistant to stretching,...

Embodiment 2

[0051] Aiming at the technical problem of difficult mechanical processing of polypropylene microporous foam boards, the first step of the present invention is to make the polypropylene microporous foam boards meet the processing hardness required for machining, and then perform machining by a numerical control machining center.

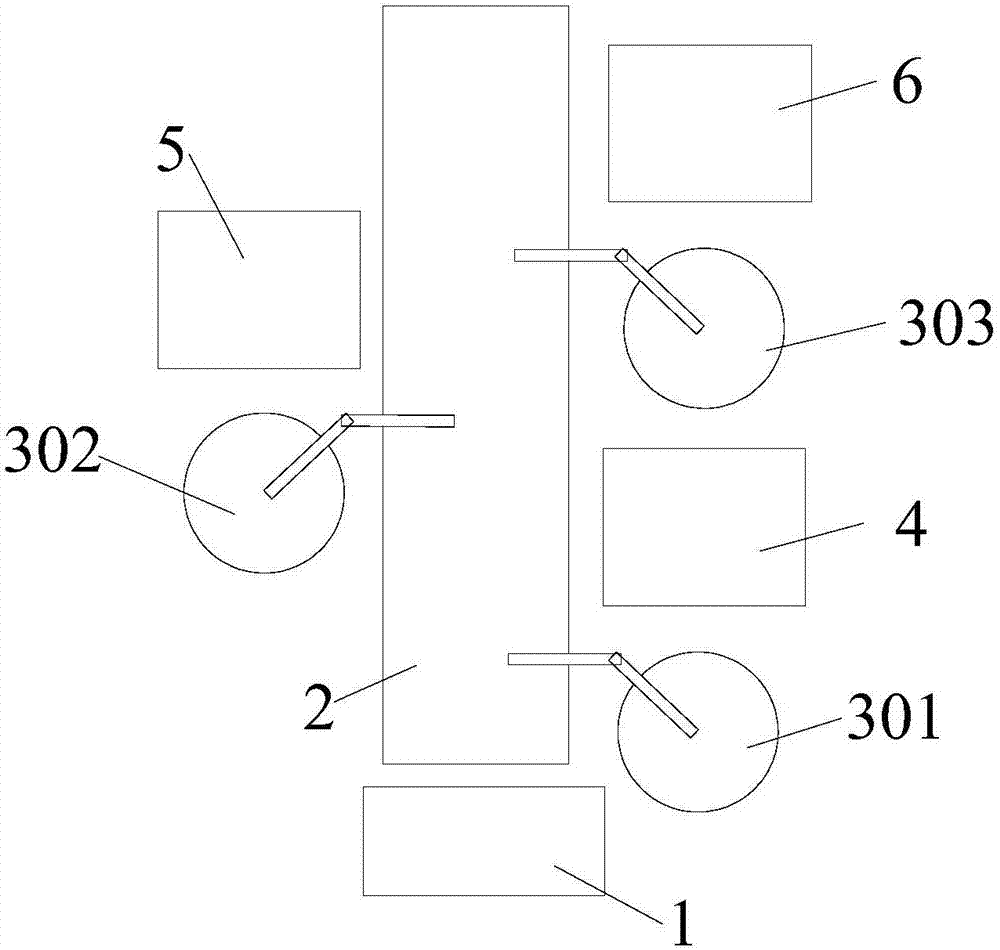

[0052] figure 2 is the top view of the wing processing system;

[0053] Such as figure 2 As shown, on the basis of Embodiment 1, Embodiment 2 provides a wing processing system.

[0054] The wing processing system includes:

[0055] Soaking tank, soaking polypropylene microporous foam board;

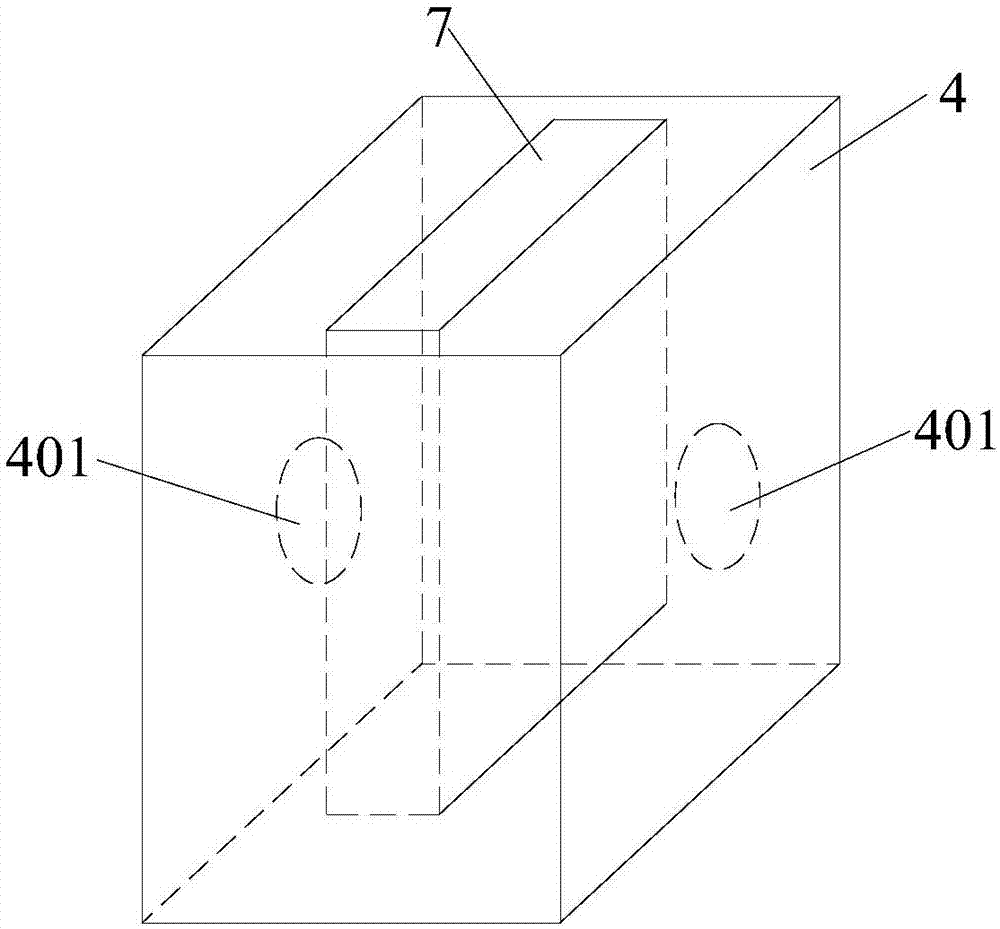

[0056] A drying device for drying the soaked polypropylene microcellular foamed sheet to harden it; and

[0057] Numerical control processing center, the polypropylene microporous foam plate after hardening is mechanically processed into the wing as described in embodiment 1; And

[0058] The grasping and conveying mechanism is used to grasp the polypropyl...

Embodiment 3

[0072] Present embodiment 3 provides a kind of wing processing method, namely

[0073] The polypropylene microcellular foamed sheet is used as a raw material, and is machined into a wing as described in Example 1.

[0074] The working method is described below by taking the wing as an example.

[0075] Figure 4 Shown is a flow chart of a method for preparing a wing using a polypropylene microporous foam board as a raw material.

[0076] Concretely, adopting polypropylene microporous foam board material as raw material to prepare the method for wing comprises the following steps:

[0077] Step S1, increasing the processing hardness of the polypropylene microcellular foamed sheet;

[0078] Step S2, cutting the polypropylene microcellular foamed sheet by the numerical control machining center described in embodiment 1, to form the semi-finished product of the wing; and

[0079] Step S3, performing thermocompression molding on the semi-finished airfoil.

[0080] Further, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com