Method for producing PHC (prestressed high-strength concrete) pipe piles by using different grades of stone

A PHC pipe pile and production method technology, applied in the field of construction concrete, can solve problems such as inability to apply, increase production costs, etc., and achieve the effects of alleviating the tight supply situation of stones, avoiding waste, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

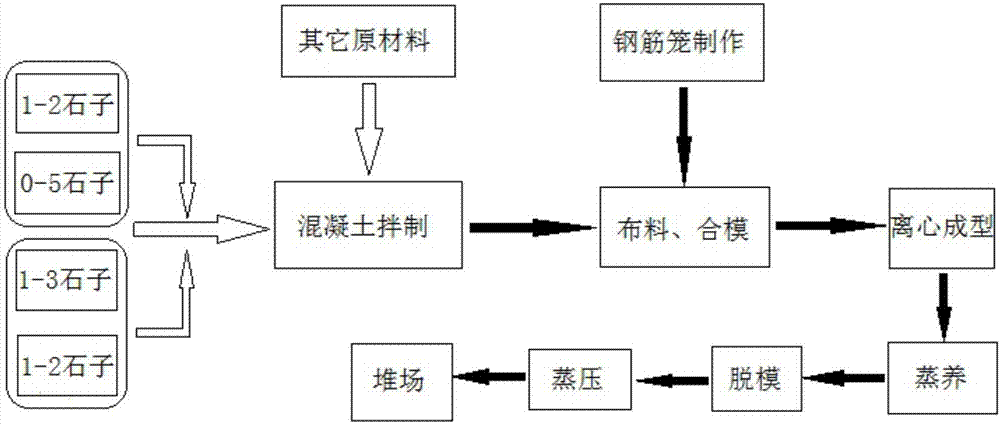

Method used

Image

Examples

Embodiment 1

[0033] Calculated per cubic concrete, take 294kg of cement, and the specific surface area is greater than 420m 2 126kg / kg of silica sand powder, 620kg of natural sand with a fineness modulus of 2.8~3.2, 119kg of 0-5 stones, of which 1203kg of 1-2 stones, 2.31kg of HQ superplasticizer (powder), 118kg of water, according to the specification PHC 400 AB 95-10 pipe piles are used to mix the concrete mixture, and then the concrete mixture is distributed into the steel mold of the pipe pile, and the prestressed steel bars are stretched at a low speed of 65r / min for 2.5 minutes, and the low-medium Speed 160r / min, time 1.0min, medium-high speed 270r / min, time 3.0min, high speed 420r / min, time 5.0min. The autoclave is subjected to autoclave curing, and after the curing is finished, it is hoisted to the storage yard, which is the whole use process of the present invention.

Embodiment 2

[0035] Calculated per cubic concrete, take 294kg of cement, and the specific surface area is greater than 420m 2 126kg / kg of silica sand powder, 620kg of machine-made sand with a fineness modulus of 2.8~3.2, 119kg of 0-5 stones, of which 1203kg of 1-2 stones, 2.31kg of HQ superplasticizer (powder), 118kg of water, according to the specification PHC 500 AB 125-12 pipe piles are used to mix the concrete mixture, and then the concrete mixture is distributed into the pipe pile steel mold, and the prestressed steel bars are stretched at a low speed of 60r / min, and the time is 3.0min. Speed 150r / min, time 1.0min, medium-high speed 250r / min, time 3.0min, high speed 380r / min, time 6.0min. The autoclave is subjected to autoclave curing, and after the curing is finished, it is hoisted to the storage yard, which is the whole use process of the present invention.

Embodiment 3

[0037] For each cubic concrete, take 280kg of cement, and the specific surface area is greater than 420m 2120kg / kg of silica sand powder, 670kg of natural sand with a fineness modulus of 2.8~3.2, 779kg of 1-3 stones, 519kg of 1-2 stones, 2.20kg of HQ superplasticizer (powder), 112kg of water, according to the specification PHC 400 AB 95-11 Pipe piles are used to mix the concrete mixture, and then the concrete mixture is distributed into the pipe pile steel mold, and the prestressed steel bars are stretched at a low speed of 65r / min for 2.5 minutes. Speed 160r / min, time 1.0min, medium-high speed 270r / min, time 3.0min, high speed 420r / min, time 5.0min. The autoclave is subjected to autoclave curing, and after the curing is finished, it is hoisted to the storage yard, which is the whole use process of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com