Fermented grain mixing device for wine stewing

A mixing device and technology of fermented grains, which is applied in the field of wine making, can solve the problems of difficult fermented grains to disperse, uneven mixing of fermented grains and bran hulls, accumulation at the lower end of the isolation plate, etc., and achieve a good effect of breaking up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

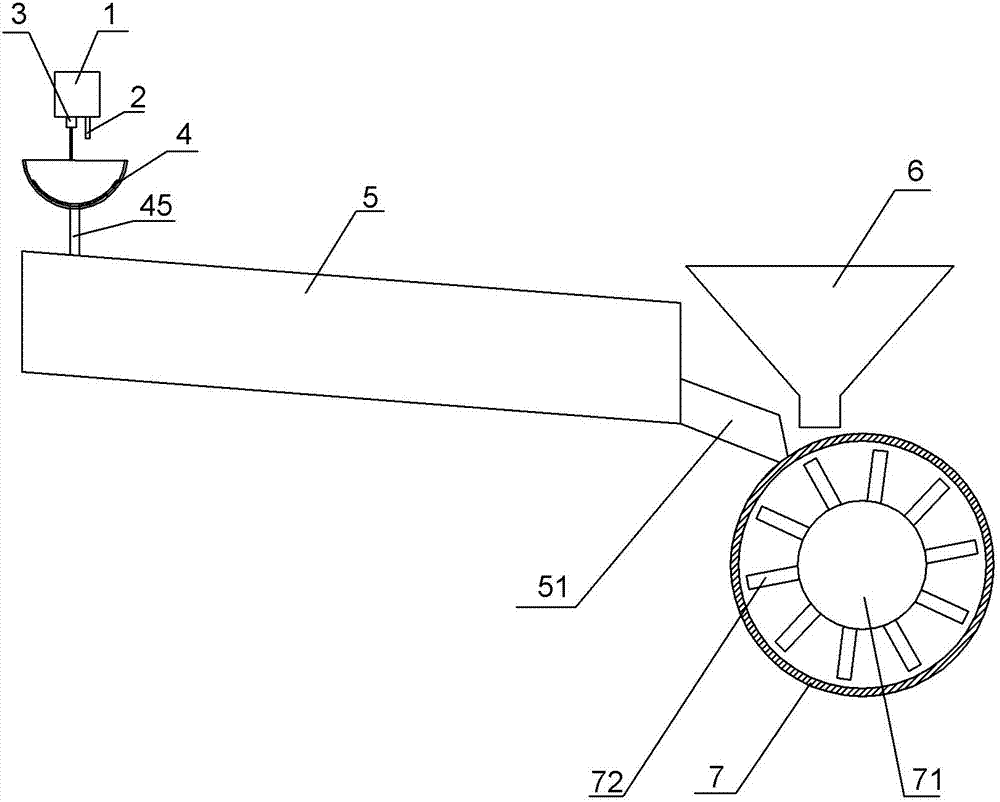

[0032] Such as figure 1 Shown:

[0033] The device for mixing fermented grains for winemaking in this embodiment includes a first feeding mechanism, a breaking mechanism, a second feeding mechanism and a mixing mechanism.

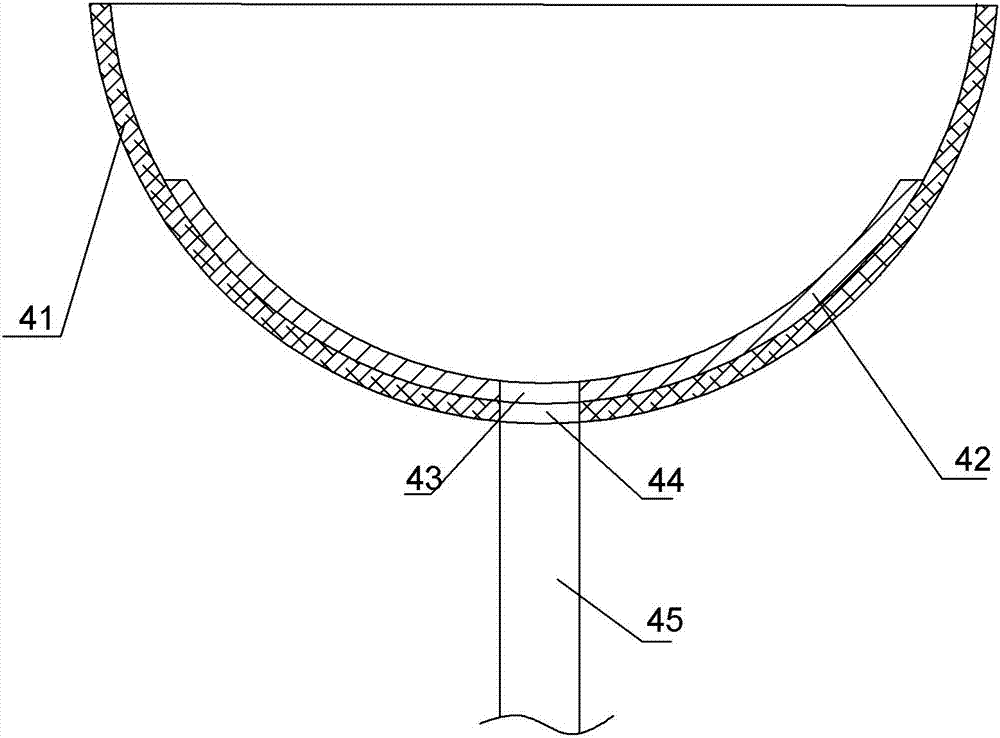

[0034] The first feeding mechanism includes a first material storage box 1, the lower end of the first material storage box 1 is connected with a first discharge port 2, and a feed tank 4 is arranged below the first material discharge port 2, and the structure of the feed tank 4 is as follows: figure 2 As shown, the feeding trough 4 includes a feeding inner tank 42 and a feeding outer tank 41, the longitudinal sections of the feeding inner tank 42 and the feeding outer tank 41 are arc-shaped and have the same arc, and the outer wall of the bottom of the feeding inner tank 42 and the feeding outer tank The inner wall of the groove bottom of 41 is attached to each other, the feeding inner groove 42 is hinged on the storage box, the feeding outer groove 41 i...

Embodiment 2

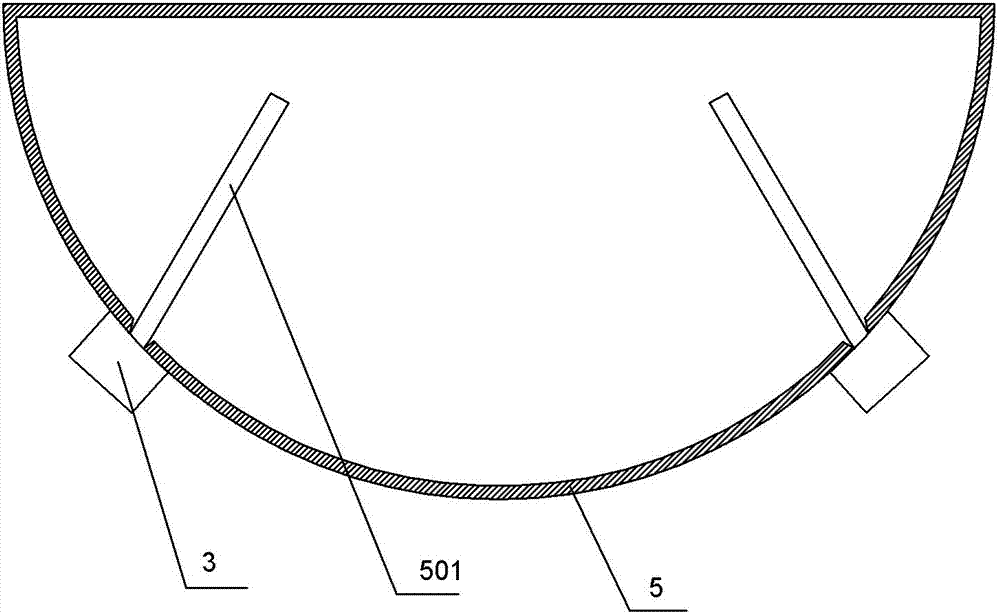

[0042] The difference between this embodiment and Embodiment 1 is that the components are broken up, such as Figure 4 As shown, in the present embodiment, a shorter fork 501 is set in the middle of two fork 501 in embodiment one, and the length of this fork 501 is 1 / 2 of the radius of the cross section of the wine fermented grains tank 5, and this fork 501 It is in a vertical state when it is not working, and the maximum rotation angle is 10 degrees when it is working.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that the components are broken up, such as Figure 5 As shown, in the present embodiment, the dispersing assembly includes four swing rods 501, which are evenly arranged along the inner wall of the wine grains tank 5, and the four swing rods 501 are located on the same cross section of the wine grains tank 5, and the edges The length of the two swing rods 501 is 3 / 4, the length of the middle two swing rods 501 is 1 / 2, and the swing directions of the two adjacent swing rods 501 are opposite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com