Metal chain-steel fiber concrete beam component

A technology of steel fiber concrete and beam components, which is applied in the field of reinforced concrete, can solve problems such as insufficient resistance, achieve the effects of improving impact resistance, excellent deformation coordination ability, and avoiding structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific embodiment of the present invention will be described in detail below in conjunction with examples.

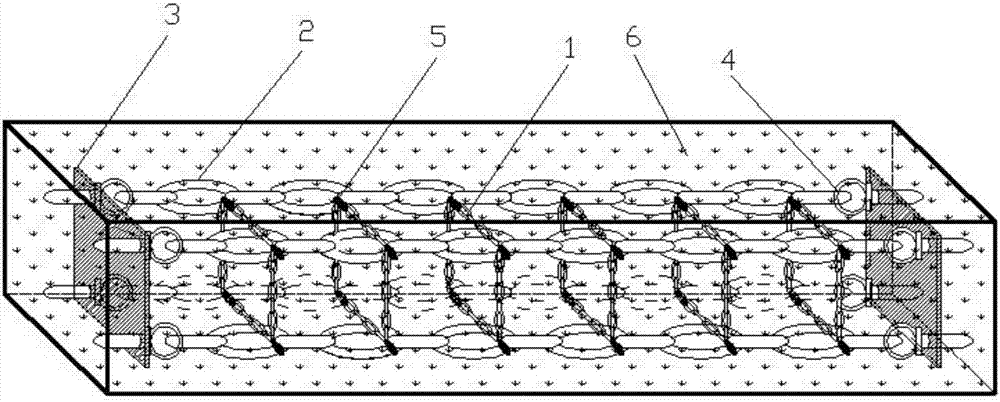

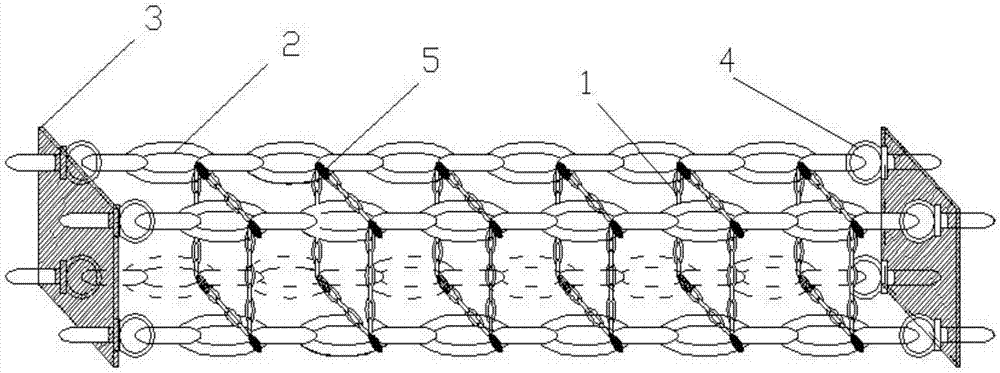

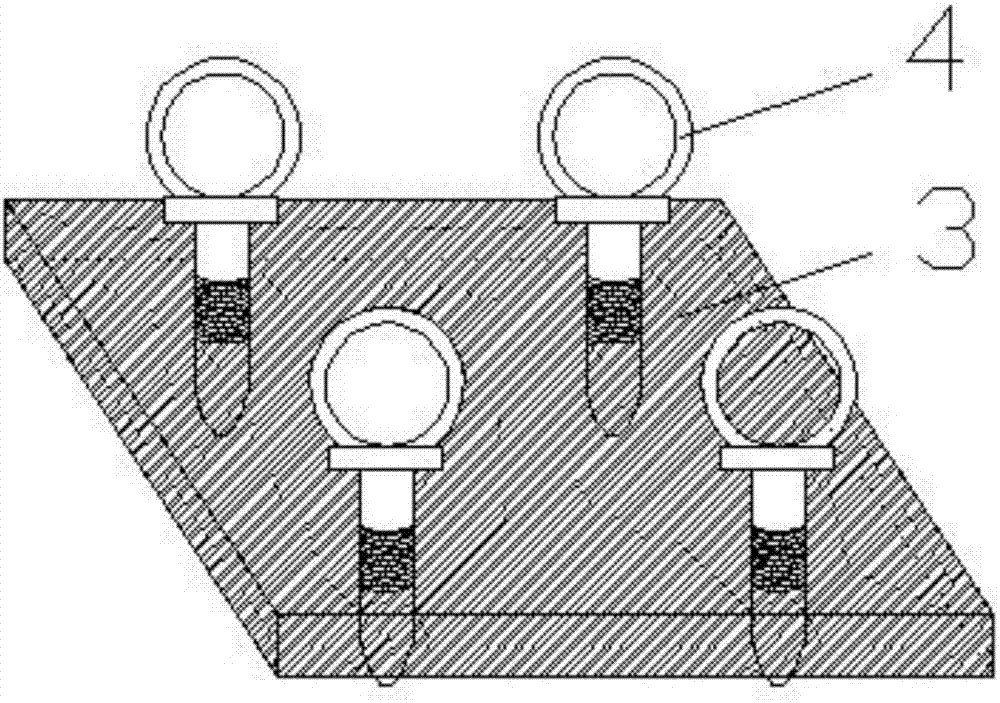

[0035] Such as figure 1 Shown, is a kind of metal chain-steel fiber concrete beam member of the present invention, and it mainly comprises stirrup chain (American standard NACM84 chain) 1, main reinforcement chain (American standard NACM90 chain) 2, end-bearing steel plate (Q345B steel plate) 3, Ring screw (M20 national standard ring screw) 4, stainless steel cable tie (304 stainless steel cable tie) 5, steel fiber concrete 6.

[0036] A 5-storey frame structure office building in a certain area has no basement. The main structure has 5 floors, and the storey height is 3.3m. The basic wind pressure w0=0.35kN / m2, and the ground roughness category is B category. The component beams in the corridor of the office building are all made of metal chain-steel plate steel fiber beams, and other components are poured with ordinary reinforced concrete. The size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com