Horizontal seepage test unit and application method thereof

A test device and seepage technology, which is applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of unstable wetting front, high production cost, inconvenient observation of wetting front time change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

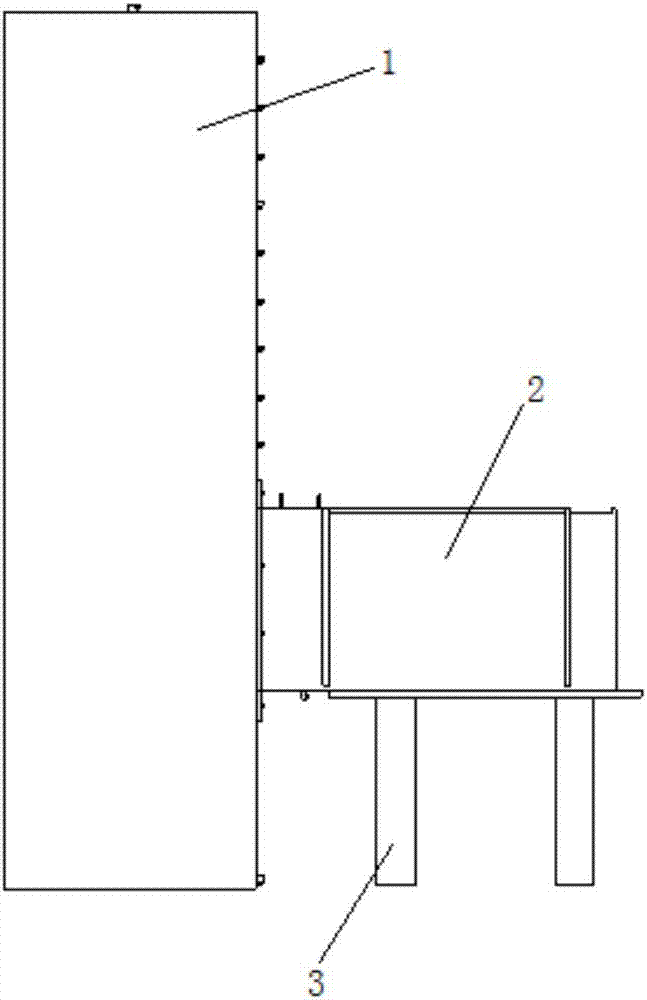

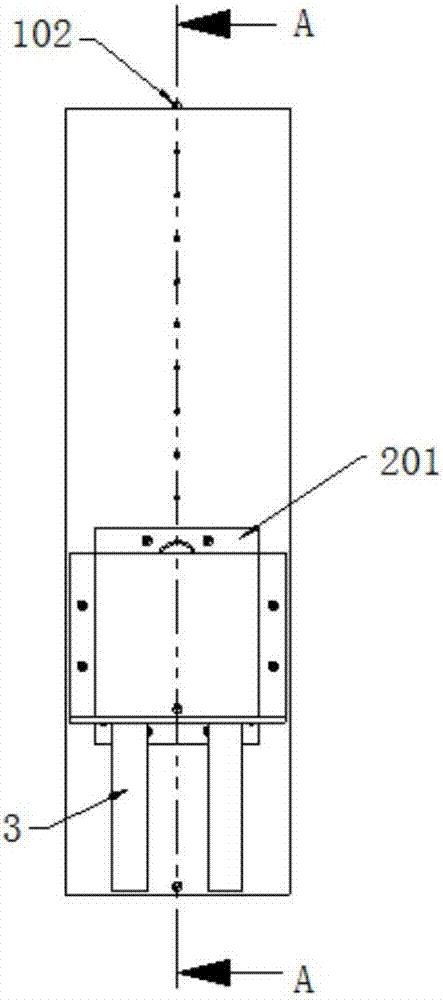

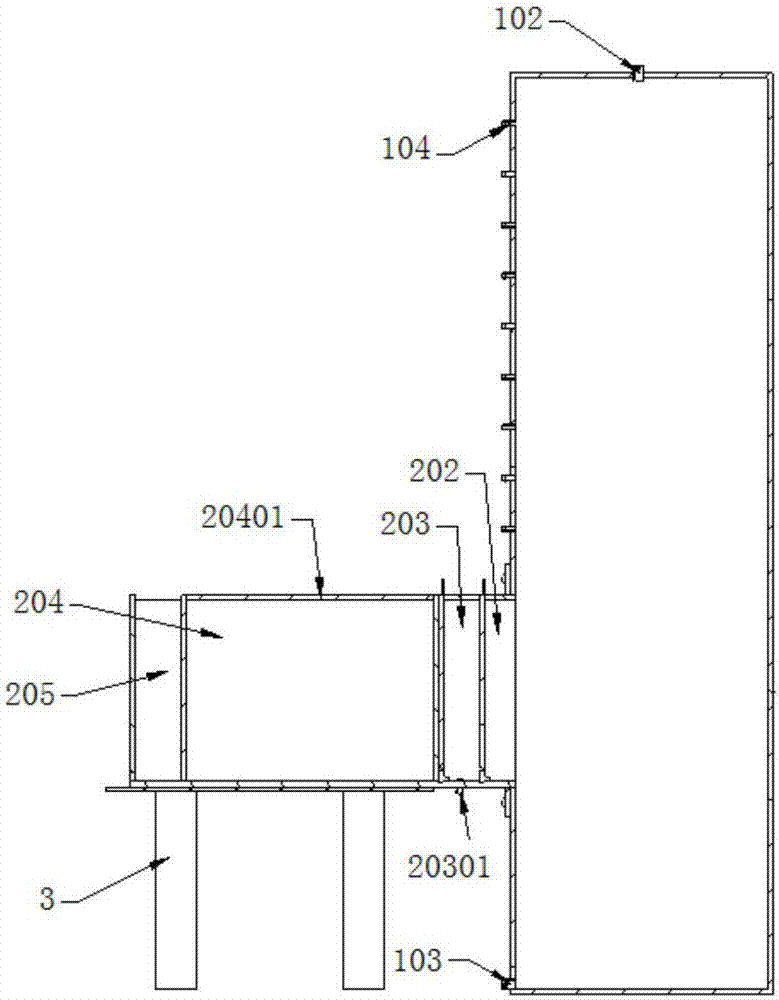

[0104] Such as Figure 1-4 As shown, a horizontal seepage test device includes a water chamber 1 , a seepage generating device 2 , and a support 3 . The seepage generating device 2 is arranged above the support 3 . The water chamber 1 is arranged on one side of the seepage generating device 2 and the support 3 . The seepage generating device 2 is a box structure. The side of the water chamber 1 close to the seepage generating device 2 is provided with a connecting port 101, and the end of the seepage generating device 2 near the water chamber 1 is provided with a water chamber connecting port 201, and the water chamber connecting port 201 of the seepage generating device 2 is connected to the The connection port 101 is connected and communicated. The seepage generating device 2 is provided with a water storage room 202 , a water isolation room 203 , an earth building tank 204 and a water collection tank 205 in order from near to far from the water chamber. The connection p...

Embodiment 2

[0106] Such as Figure 5-13As shown, embodiment 1 is repeated, except that the water chamber 1 is a cuboid structure. The top of the water chamber 1 is provided with a water chamber water inlet flow valve 102 . The side bottom of the water chamber 1 is provided with a water chamber drain valve 103 . A water level regulating valve 104 is provided on the side of the water chamber 1 and above the horizontal position of the seepage generating device 2 . The seepage generating device 2 is a box structure. One end of the seepage generating device 2 is an open structure and is connected and communicated with the connection port 101 of the water chamber 1 . The seepage generating device 2 further includes a first cover plate 206 , a first water barrier plate 207 , a second water barrier plate 208 , a first porous plate 209 , and a second porous plate 210 . The front end of the top of the seepage generating device 2 is fixed with a first cover plate 206, and the first cover plate 2...

Embodiment 3

[0108] Repeat Example 2, except that the side of the water chamber 1 is provided with 12 water level regulating valves 104 . Ten test holes 20402 are provided on the second cover plate 20401 . The water chamber 1 and the seepage generating device 2 are made of acrylic material.

[0109] Use Example 1

[0110] Using the method of embodiment 2, a kind of method of testing horizontal seepage, the method comprises the following steps:

[0111] 1) Configure materials similar to the rock-soil medium, and determine the filling density of the material and the thickness of the layered filling;

[0112] 2) insert the first water barrier 207, the second water barrier 208, the first porous plate 209, the second porous plate 210 in the seepage generating device 2, and paste the first barrier on the first water barrier 207 Water plate waterproof strip 20703, paste the second water barrier strip 20803 on the second water barrier 208, respectively seal the contact surfaces of the first por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com