A kind of soft magnetic material and preparation method thereof

A soft magnetic material and preparation process technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of low comprehensive performance of the iron core, achieve excellent soft magnetic properties, ensure magnetic properties, and good performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

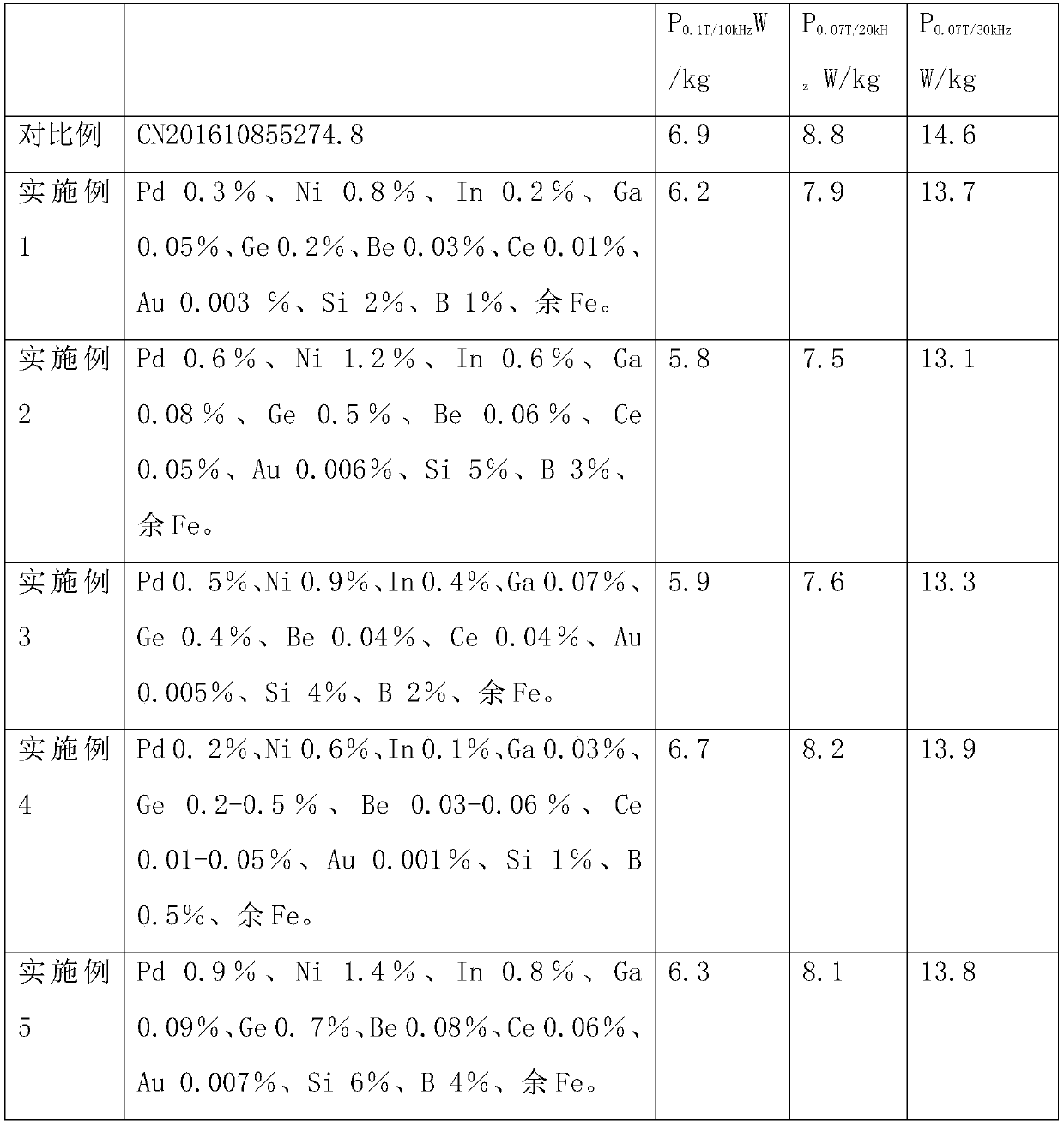

[0025] The present invention will be further described below in conjunction with specific examples.

[0026] A soft magnetic material, which comprises the following components in terms of weight percentage:

[0027] Pd 0.3-0.6%, Ni 0.8-1.2%, In 0.2-0.6%, Ga 0.05-0.08%, Ge 0.2-0.5%, Be0.03-0.06%, Ce 0.01-0.05%, Au 0.003-0.006%, Si 2-5%, B 1-3%, Fe balance.

[0028] The specific process of the preparation process is as follows:

[0029] First carry out batching according to above-mentioned alloy composition, the purity of Pd, Ni, In, Ga, Ge, Be, Ce, Au, Fe in the raw material is all greater than 99.9%; B is added in the form of boron-iron alloy, wherein the weight percentage of B is 24% %;

[0030] The raw materials are melted in a vacuum induction furnace at a melting temperature of 1480-1500°C to obtain a master alloy, which is then put into a remelting tubular crucible in a vacuum induction forming furnace for remelting at a remelting temperature of 1500-1520°C; There is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com