Waterproof structure of dry-type transformer

A technology of dry-type transformers and transformers, which is applied in transformer/inductor components, transformer/inductor shells, transformer/inductor cooling, etc., and can solve problems such as single structure, unfavorable heat, and imperfect considerations, etc., to achieve increased Large shading range, increased heat dissipation efficiency, and guaranteed connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

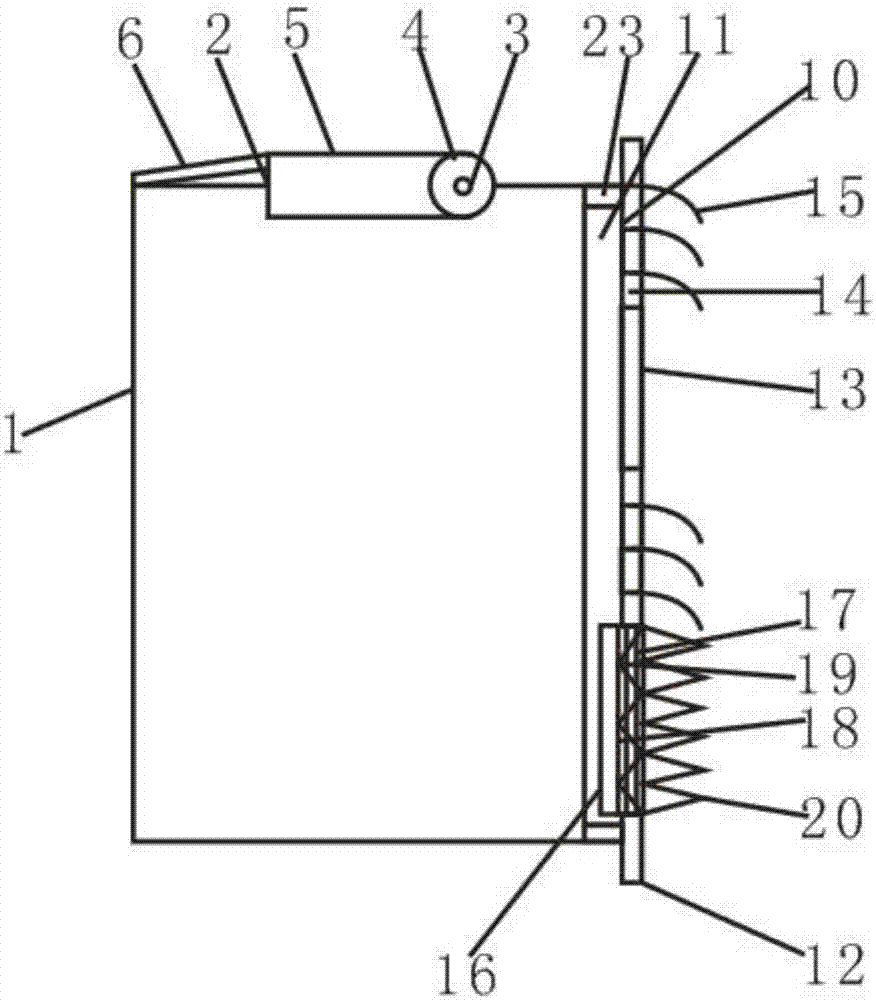

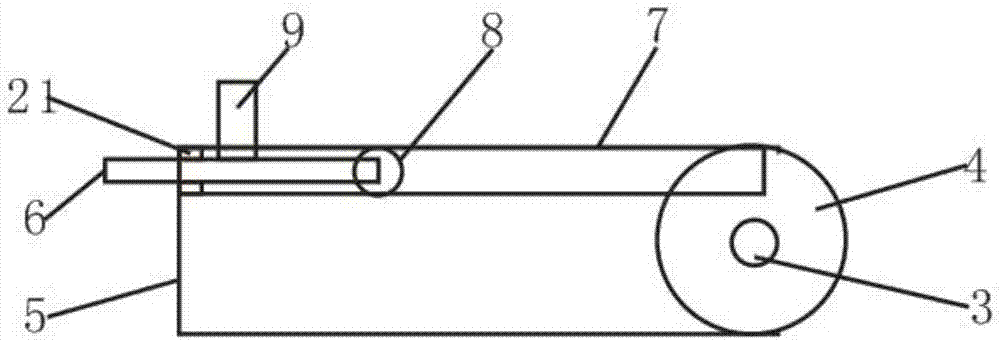

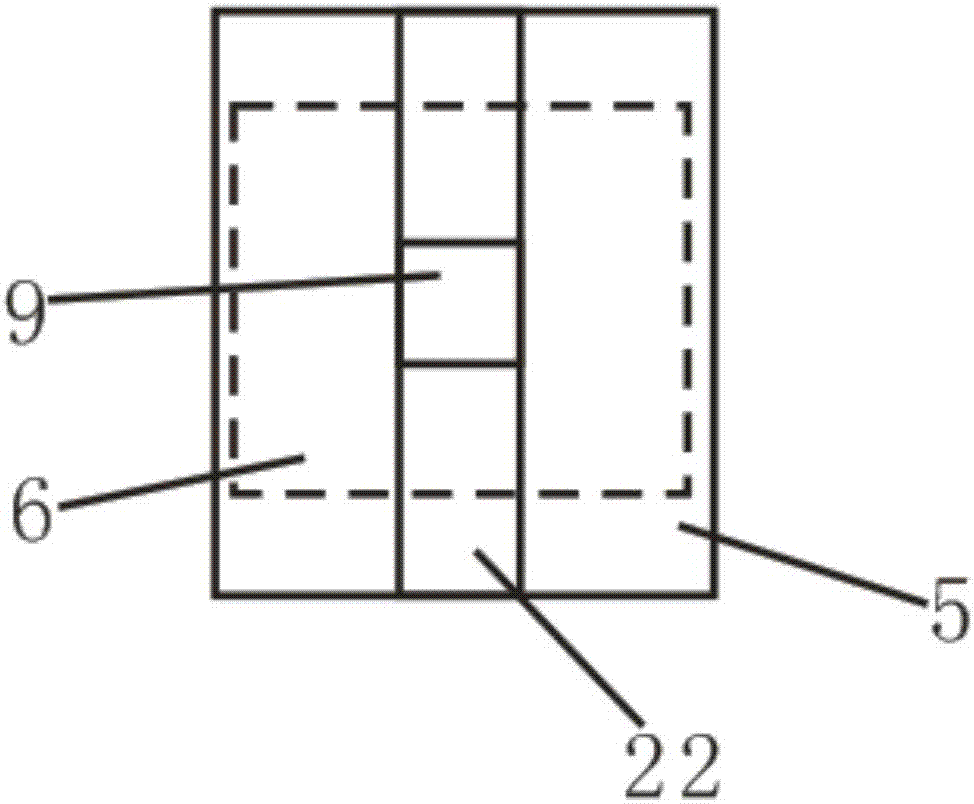

[0020] like figure 1 , figure 2 and image 3 As shown, the present invention provides a waterproof mechanism for dry-type transformers, including a transformer outer box 1, the top of the transformer outer box 1 is provided with a top heat dissipation hole 2, the top heat dissipation hole 2 increases heat dissipation efficiency, and the top heat dissipation hole 2 A rotating shaft 3 is connected inside, and a rotating ring 4 is arranged on the outside of the rotating shaft 3. A shroud 5 is connected to the outer side of the rotating ring 4. The shroud 5 is used to shield the top during the heat dissipation process. The shroud 5 and the top The heat dissipation holes 2 are all rectangular in shape, and the areas of the two rectangles are equal. The inside of the shutter 5 is provided with an expansion plate 6 and an expansion slot 7. The expansion plate 6 is located inside the expansion slot 7, and the expansion slot The end of 7 is provided with a shielding ring 21, the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com