Long-travel magnetic ring winding machine

A wrap-around, long-stroke technology, used in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem of inappropriate large magnetic ring multi-coil magnetic ring processing, etc., and achieve good processing quality and wire drawing time. The effect of shortening and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

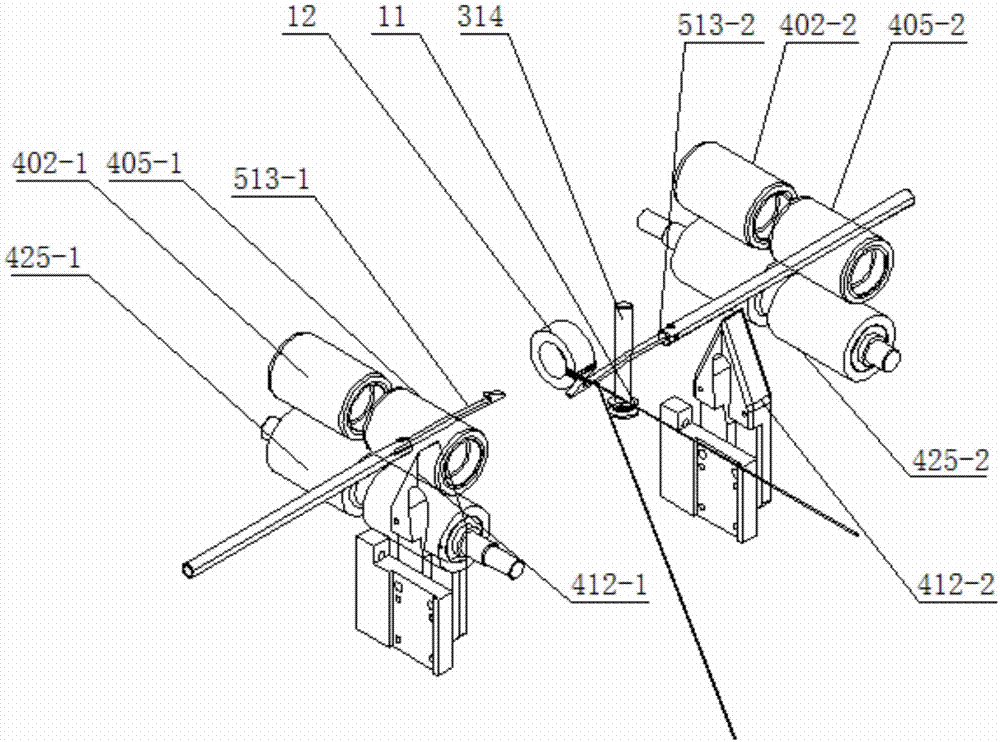

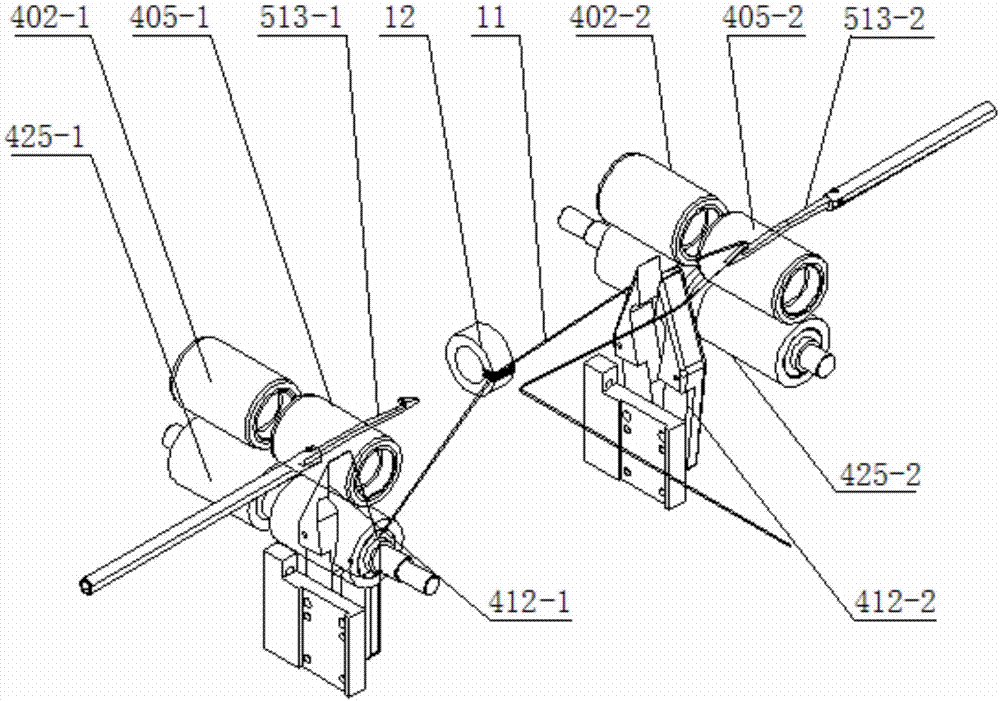

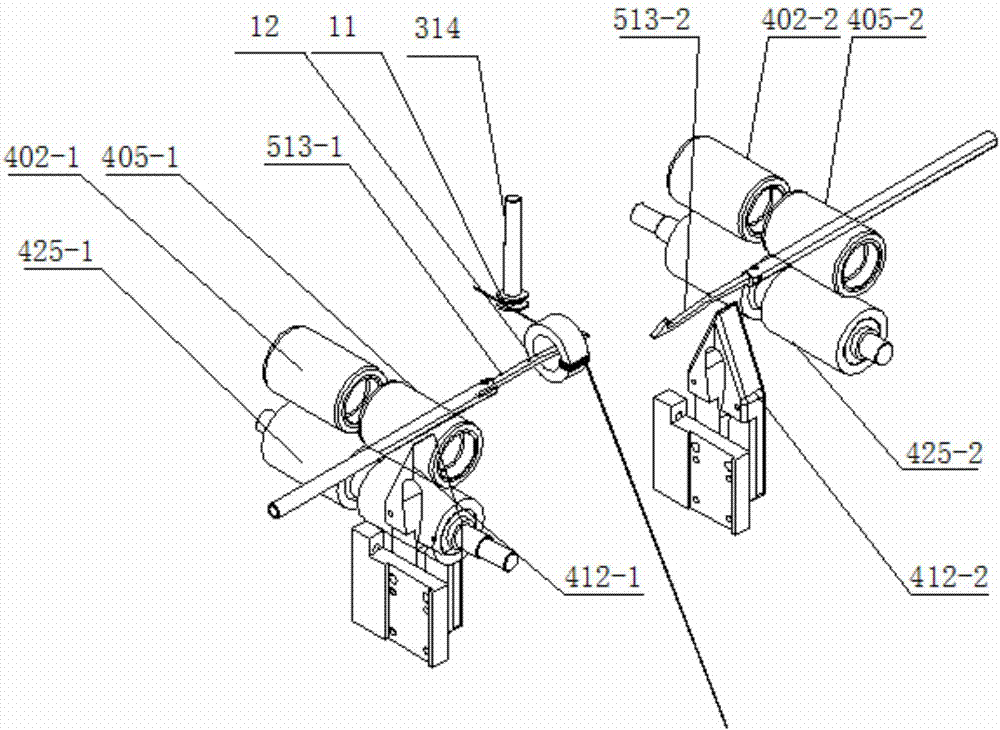

[0025] refer to Figure 1A , Figure 1B , Figure 2A , Figure 2B , the winding principle is that the copper wire 11 is sent into the inner hole of the magnetic ring 12 through the wire feeding and trimming mechanism 9, and the dial wheel 314 dials the copper wire 11 to the position in step 1, and presses the copper wire 11 to the side of the magnetic ring. The crochet needle 513 runs to the position shown in the figure, and the copper wire 11 is Figure 1B Position stretching, when the crochet is close to the second copper wire support plate 412-2 of the short roller, the second copper wire support plate 412-2 rises and opens the scissors, expanding the gap in the middle of the copper wire 11 so that it can enter the first short roller. Between the roller Ⅱ 402-2 and the second short roller Ⅱ 405-2, then the second short roller Ⅱ 405-2 starts to press down and engage with the second long roller 415-2, and the second long roller 415-2 keeps rotating to drive the second The sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com