Mass transfer method of Micro LED (Light Emitting Diode) chips

A technology of light-emitting diodes and chips, which is applied in the directions of printed circuits, printed circuits, and electrical components connected with non-printed electrical components, can solve the problems of waste, low yield, and high production cost of MicroLED chips, and achieves mass transfer, The effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

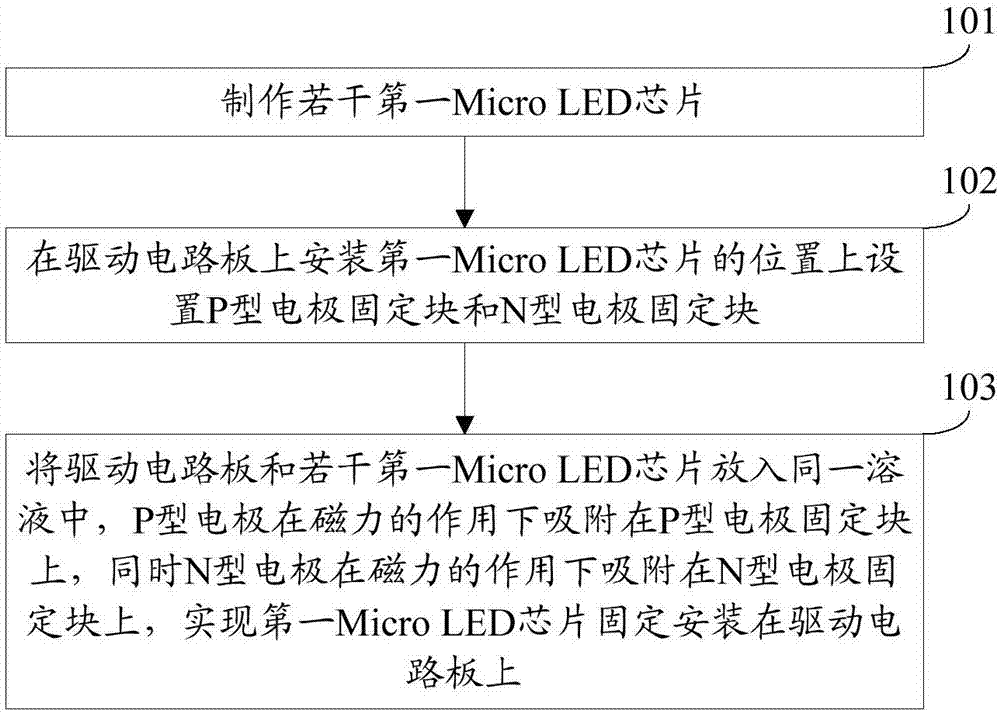

[0054] The embodiment of the present invention provides a method for mass transfer of Micro LED chips, see figure 1 , the method includes:

[0055] Step 101: Fabricate a number of first Micro LED chips.

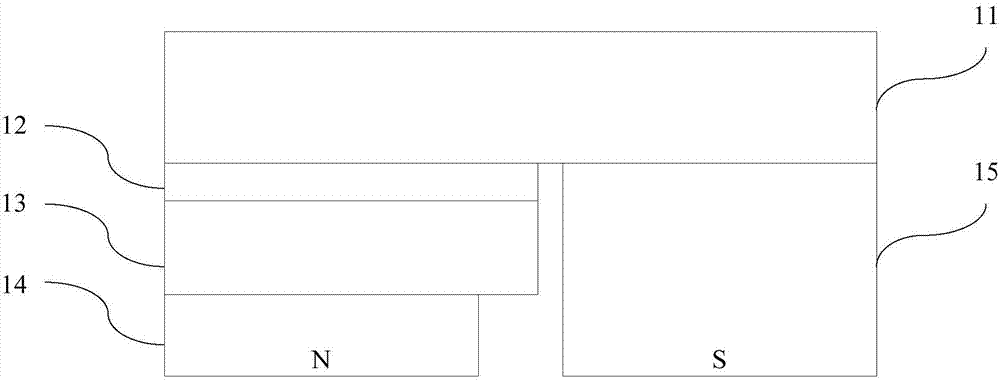

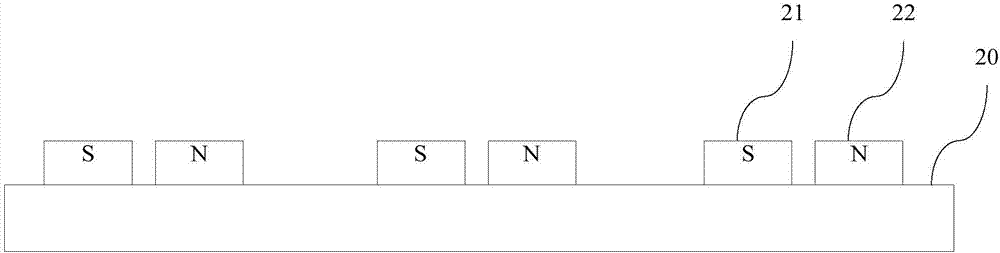

[0056] In this embodiment, the first Micro LED chip includes an N-type layer, a light-emitting layer, a P-type layer, a P-type electrode, and an N-type electrode. The N-type layer, the light-emitting layer, and the P-type layer are stacked in sequence. The groove extending to the N-type layer, the N-type electrode is arranged on the N-type layer in the groove, the P-type electrode is arranged on the P-type layer, the P-type electrode and the N-type electrode are magnets, and the P-type electrode is far away from the P-type layer One end of the N-type electrode and the end of the N-type electrode away from the N-type layer are heteronym magnetic poles.

[0057] Specifically, the maximum distance between two points on the cross section of the first Micro LED chip perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com