Micro-LED chip mass transfer method

A technology of LED chip and transfer method, which is applied in the manufacture of semiconductor devices, electrical components, semiconductor/solid-state devices, etc. It can solve the problems of insufficient precision, small micro-LED chips, and unsatisfactory yield, so as to achieve cost saving and high precision , The effect of simple and fast mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1, the micro LED chip is a vertical chip

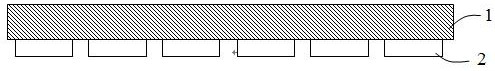

[0028] After the epitaxial structure is grown on the surface of the sapphire substrate, the device discrete grooves are etched in the epitaxial structure, and the distance between the centers of adjacent devices is 20 μm; the reflective layer material Ag, the isolation material TiW and the bonding material AuIn are sequentially deposited on the p surface of each device . Afterwards, perform a visual inspection and record the location of good products.

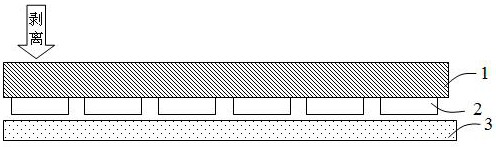

[0029] According to the results of visual inspection, use the laser lift-off method to peel off the good chip from the sapphire substrate and drop it on the adhesive film (temporary carrier); in the process of peeling the chip, arrange the fallen chips by moving the adhesive film In a square array, the distance between the centers of adjacent chips in the array is 20 μm*100 μm. Before the chip falls, the adhesive film is about 1mm away from the chip.

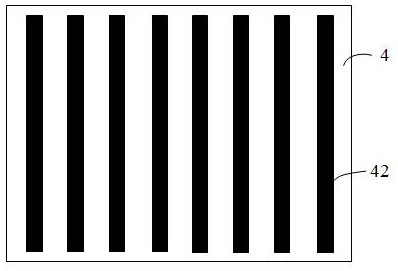

[0030] Use PDMS...

example 2

[0033] Example 2, the micro LED chip is a flip chip

[0034] After the epitaxial structure is grown on the surface of the sapphire substrate, the fabrication of the flip chip is completed and the chips are separated. The distance between the center points of adjacent chips in the horizontal and vertical directions is 100 μm*80 μm. After depositing the bonding material AuIn on the surface of the chip, perform a visual inspection and record the position of the good product.

[0035] According to the results of visual inspection, use the laser lift-off method to peel off the good chip from the sapphire substrate and drop it on the adhesive film (temporary carrier); in the process of peeling the chip, arrange the fallen chips by moving the adhesive film In a square array, the distance between the centers of adjacent chips in the array is 100 μm*80 μm. Before the chip falls, the adhesive film is about 1mm away from the chip.

[0036] Use PDMS to make a stamp as shown in Figure 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com