Water-soluble mussel extract

A water-soluble, extractable technology used in nutritional and medical applications to solve the problems of mussel powder insoluble, unpleasant "fishy" smell, unsuitable for inclusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

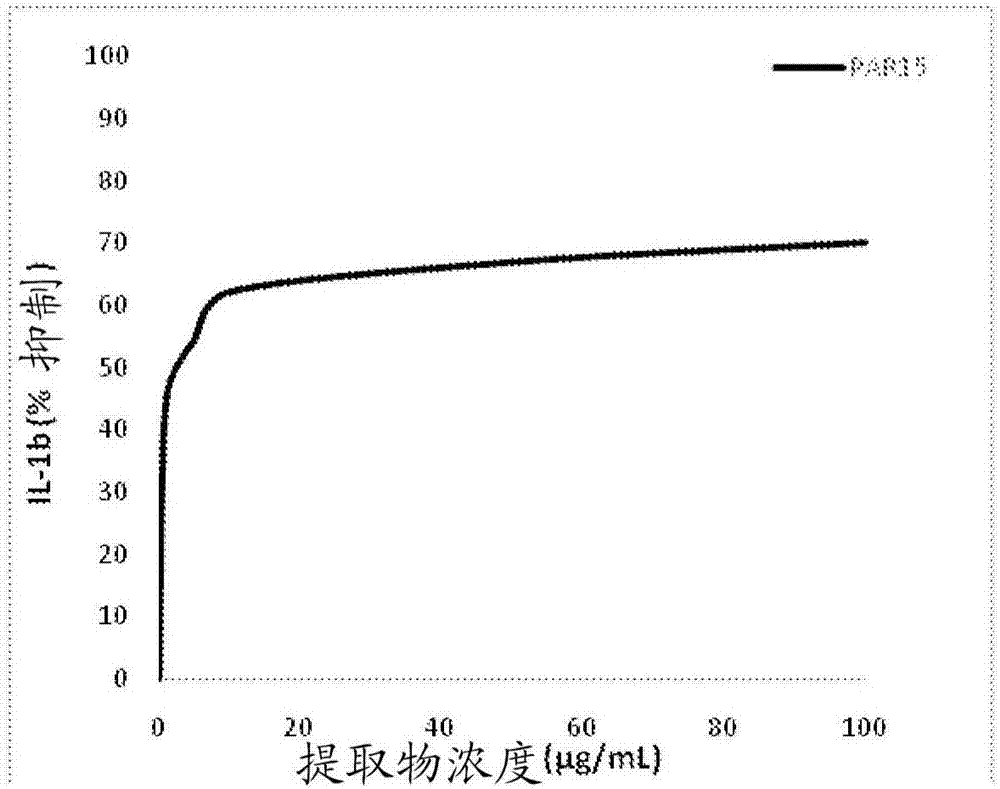

[0191] Example 1: Extraction of Green Shell Mussel Supercritical Slag (GSM Slag Extract) PAR 15

[0192] Supercritical CO from freeze-dried green shell mussels (160 g) 2 The extracted slag was suspended in 600ml of water. Oxyless U antioxidant (0.25g) was added. Papain (5ml) was added and the mixture was heated to 55°C in a shaking water bath for 1 hr. Then, Enzidase FP (0.5 g) was added and hydrolysis was continued for another 1 hr at 55°C in a shaking water bath.

[0193]The hydrolysis mixture was heated at 90°C for an additional 30 min, cooled to 55°C, then centrifuged at 10000 rpm for 30 min, after which time the supernatant (565ml) was recovered. The pH of the supernatant was adjusted to pH 4 with phosphoric acid. Activated carbon (2 g) was added. The supernatant was filtered through a Seitz 900 filter plate using diatomaceous earth (20 g pre-cover (Celite HyFlo) + 20 g bulk charge (Celite 545)). The filtrate (510ml) was recovered and mixed with maltodextrin (27.2g)...

Embodiment 2

[0199] Example 2: Extraction of Whole Fresh Green Shell Mussel (Whole Fresh GSM Extract) PAR 37

[0200] Homogenized meat (500 g) from green shell mussels was suspended in 400 ml water. Oxyless U antioxidant (0.25g) was added. Alcalase (2.5ml) and Enzidase Neutral (2.5ml) were added and the mixture was heated to 60°C in a shaking water bath for 3hr. Then, Enzidase FP (0.125 g) was added and hydrolysis was continued for another 1 hr at 60°C in a shaking water bath.

[0201] The hydrolysis mixture was heated at 95°C for an additional 40 min, cooled to 55°C, then centrifuged at 10000 rpm for 30 min, after which time the supernatant (795 ml) was recovered. The pH of the supernatant was adjusted to pH 4 with phosphoric acid. Activated carbon (2 g) was added. The supernatant was filtered through a Seitz 900 filter plate using Celite (2Og pre-cover + 2Og body charge). The filtrate (750ml) was recovered and mixed with maltodextrin (27.2g) and Oxyless U antioxidant (0.25g) until d...

Embodiment 3

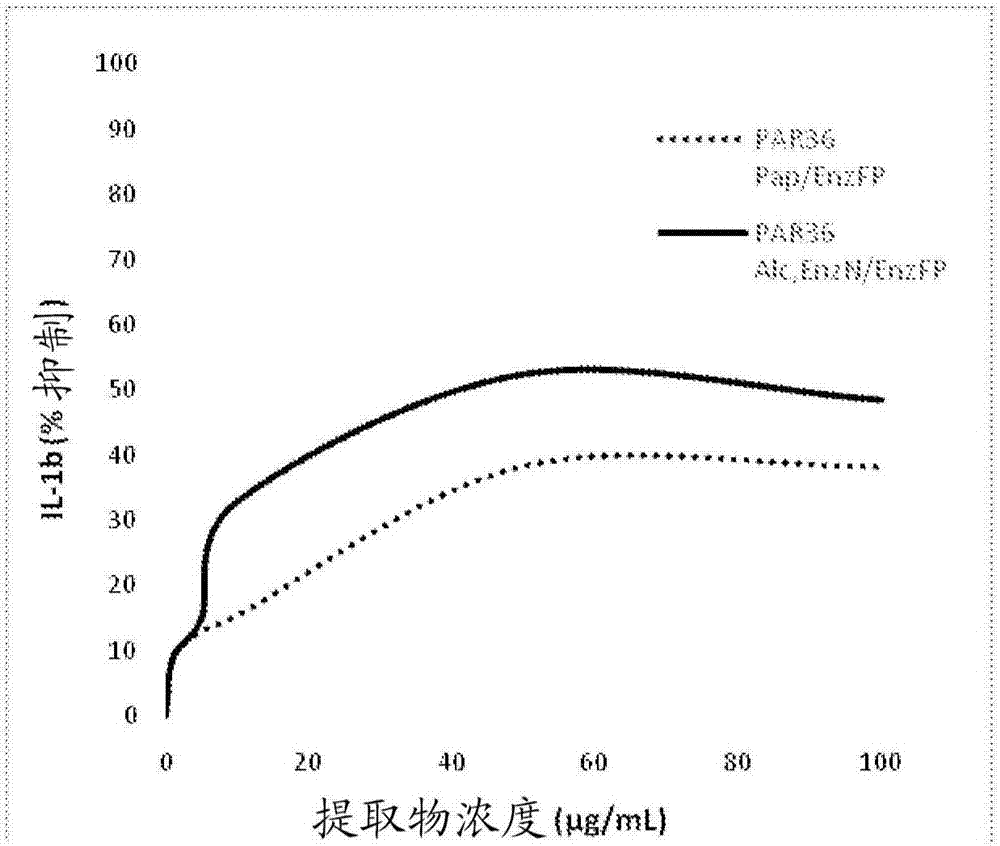

[0205] Embodiment 3: Extraction of GSM whole powder (GSM whole powder extract) PAR 36

[0206] Freeze-dried powdered green shell mussels (160 g) were suspended in 600 ml of water. Oxyless U antioxidant (0.25 g) was added and the pH was adjusted from 6.0 to 8.0. Alcalase (2.5ml) and Enzidase Neutral (2.5ml) were added and the mixture was heated to 60°C in a shaking water bath for 3hr. Then, Enzidase FP (0.125 g) was added and hydrolysis was continued for another 1 hr at 60°C in a shaking water bath.

[0207] The hydrolysis mixture was heated at 95°C for an additional 40min, cooled to 55°C, then centrifuged at 10000rpm for 30min, after which the supernatant (590ml) was recovered. The pH of the supernatant was adjusted to pH 4 with phosphoric acid. Activated carbon (2 g) was added. The supernatant was filtered through a Seitz 900 filter plate using Celite (2Og pre-cover + 2Og body charge). The filtrate (550ml) was recovered and mixed with maltodextrin (27.2g) and Oxyless U a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com