Disc Rotor- And Axial Flux-Type Rotating Electric Machine

A technology of axial magnetic flux and rotating motors, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuits, electromechanical devices, etc., can solve problems such as high production costs, achieve simple structure, low moment of inertia, Effect of Torque Increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

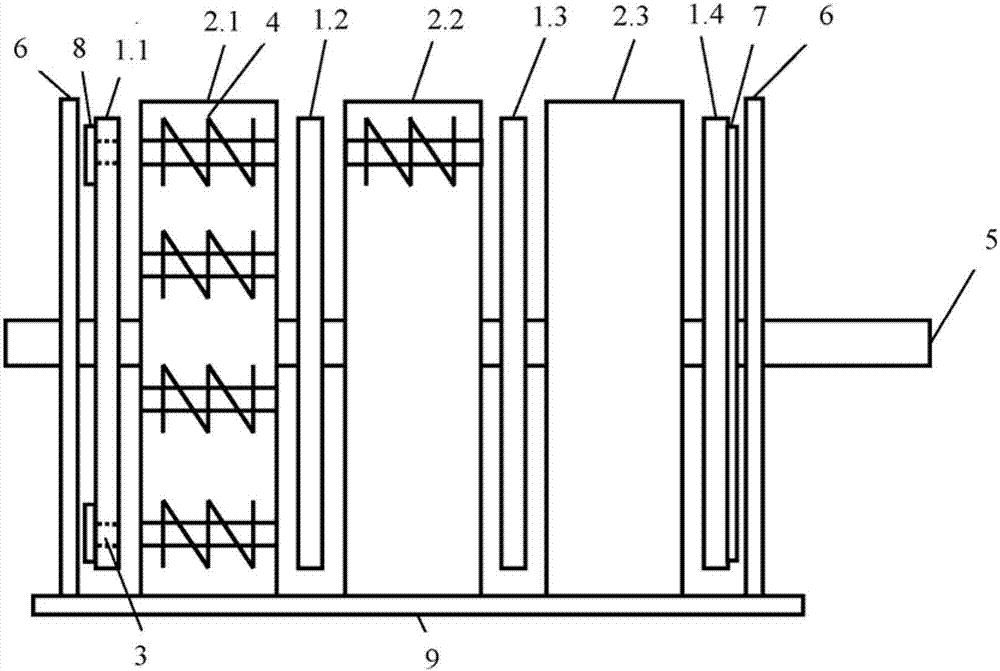

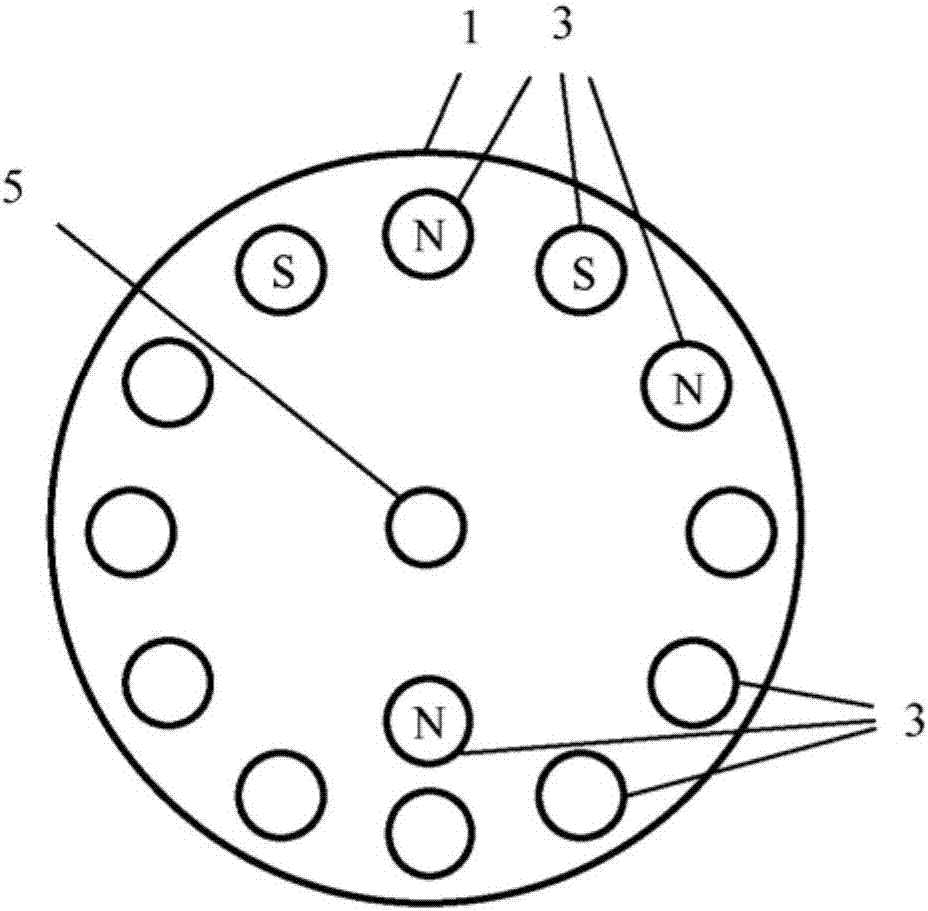

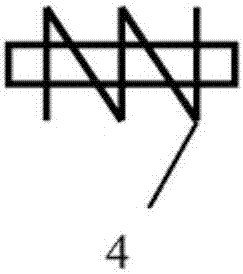

[0021] figure 1 An electric machine according to the invention is shown with three stators 2.1 to 2.3 and four rotors 1.1 to 1.4. The stators 2.1 to 2.3 have in any case twelve coils 4 (see also attached Figure 4 ) and the rotors 1.1 to 1.4 have in any case 16 permanent magnets 3 . In this example, the permanent magnets are arranged in a continuous manner in the rotors 1.1 to 1.4, ie the permanent magnets 3 end flush with the surface of the rotors 1.1 to 1.4. The coils 4 and the permanent magnets 3 are located in each case respectively on annular paths in the rotors 1.1 to 1.4 and in the stators 2.1 to 2.3 and correspond to each other. The shaft 5 is mounted in the stators 2.1 to 2.3. It is also possible that the shaft 5 is mounted in the leftmost and rightmost stator disks 6 . The stators 2.1 to 2.3 are fastened to the base plate 9. The coil 4 is wound on a cylindrical core, preferably of ferrite material. The cross-section of the core and the ends of the core can devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com