Thumb function rehabilitation exoskeleton robot

An exoskeleton robot and exoskeleton technology, applied in the field of rehabilitation robots, can solve the problems of unsatisfactory rehabilitation treatment effects, lack of perception functions, etc., and achieve the effects of convenient preloading, reducing impact, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

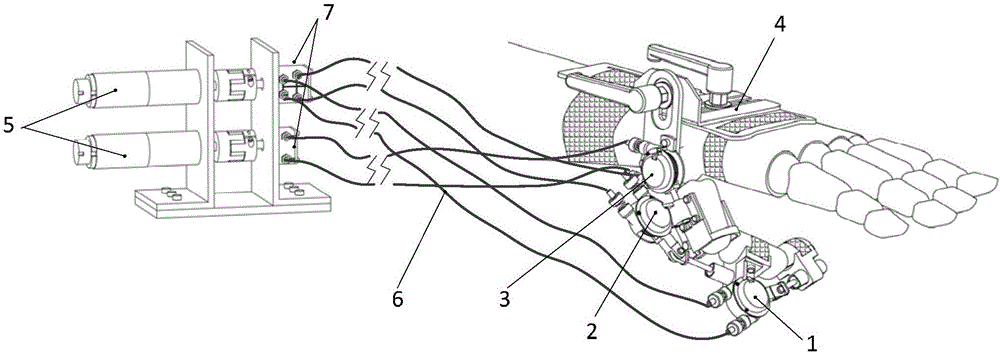

[0034] Specific implementation mode one: as Figure 1-8 As shown, the exoskeleton robot for thumb function rehabilitation in this embodiment includes an exoskeleton actuator and a transmission drive mechanism, and the exoskeleton actuator includes an interphalangeal joint unit 1, a metacarpophalangeal joint unit 2, a carpal joint unit 3 and a palm The adjustment mechanism 4, wherein the interphalangeal joint unit 1 and the metacarpophalangeal joint unit 2 both use a planar guide rod mechanism to drive the interphalangeal joint and the metacarpophalangeal joint of the thumb to perform flexion or extension movements; The adduction or abduction movement of the wrist joint is directly aligned with the wrist joint of the thumb; the transmission drive mechanism uses a DC motor 5 as a power source, and the winding wheel module 7 transmits the torque output by the DC motor 5 through the Bowden wire 6 To interphalangeal joint unit 1, metacarpophalangeal joint unit 2 and carpal joint un...

specific Embodiment approach 2

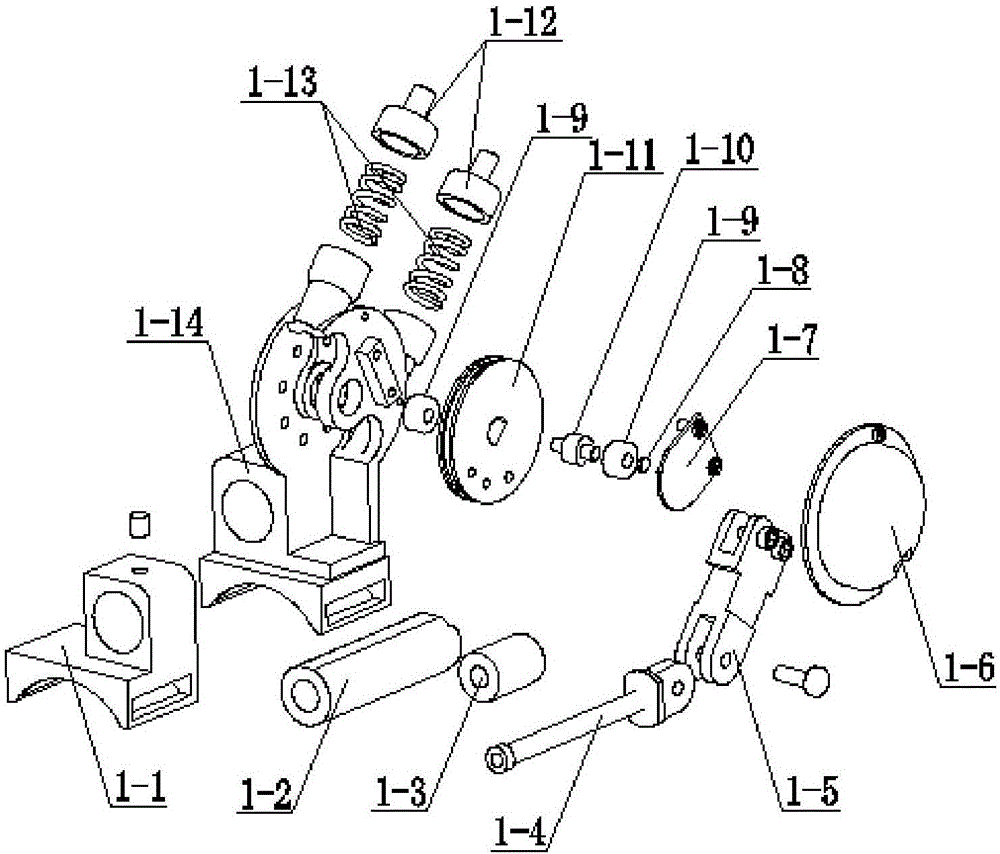

[0035] Specific implementation mode two: as figure 2 As shown, the interphalangeal joint unit 1 in this embodiment includes the distal phalanx base 1-1, the first joint guide sleeve 1-2, the first joint linear bearing 1-3, the first joint guide rod 1-4, the first joint guide rod 1-4, One joint connecting rod 1-5, first joint end cover 1-6, first joint angular displacement sensor 1-7, first joint magnetic steel 1-8, two first joint bearings 1-9, first joint D-shaped shaft 1-10, first joint wire wheel 1-11, two first joint sleeves 1-12, two first joint pressure springs 1-13 and proximal phalanx seat 1-14; distal phalanx seat 1-1 is fixed on the distal phalanx by Velcro, the proximal phalanx base 1-14 is fixed on the proximal phalanx by Velcro, and the first joint guide sleeve 1-2 is fixed on the distal phalanx base 1-1 , the first joint linear bearing 1-3 is fixedly embedded in the first joint guide sleeve 1-2, one end of the first joint guide rod 1-4 is mounted on the first j...

specific Embodiment approach 3

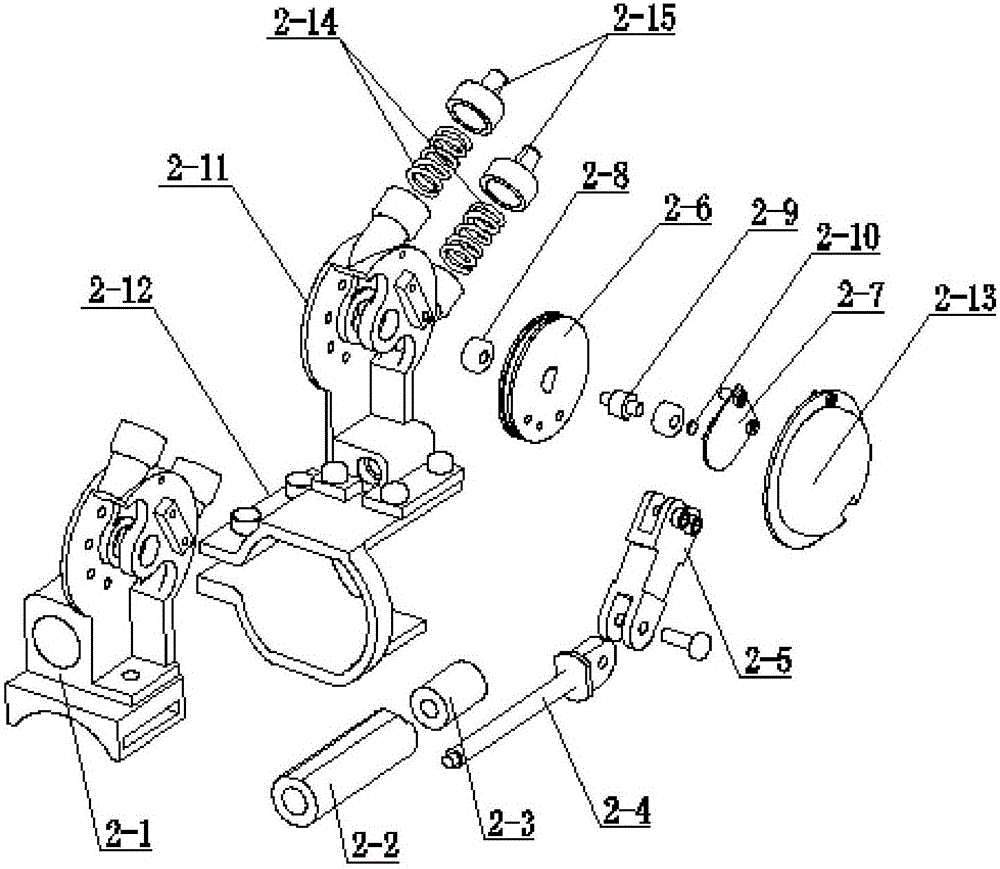

[0036] Specific implementation mode three: as image 3 As shown, the metacarpophalangeal joint unit 2 of this embodiment includes a second joint guide sleeve 2-2, a second joint linear bearing 2-3, a second joint guide rod 2-4, a second joint connecting frame rod 2-5, Two-joint wire wheel 2-6, second joint angular displacement sensor 2-7, two second joint bearings 2-8, second joint D-shaped shaft 2-9, second joint magnetic steel 2-10, metacarpal base 2 -11, metacarpal ring 2-12, second joint end cap 2-13, two second joint pressure springs 2-14 and two second joint sleeves 2-15; second joint guide sleeve 2-2 wear It is fixed on the proximal phalanx base 1-14, the second joint linear bearing 2-3 is fixedly embedded in the second joint guide sleeve 2-2, and one end of the second joint guide rod 2-4 is mounted on the second joint linear bearing 2-3, the other end of the second joint guide rod 2-4 is rotationally connected with one end of the second joint connecting frame rod 2-5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com