Lorry cooling tank for expressway service areas

A technology for highways and cooling pools, applied in roads, roads, buildings, etc., can solve problems such as threats to human health and environmental protection, weak high-pressure waterproof performance, etc., to protect the surrounding water environment, prevent water leakage, and high-pressure waterproof performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

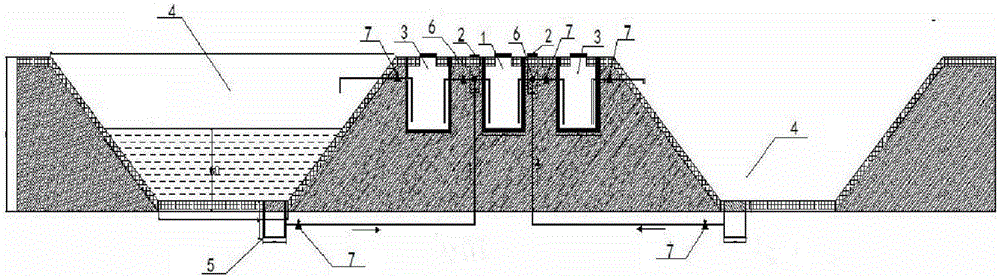

[0019] A truck cooling pool in an expressway service area, the truck cooling pool includes a grease trap 1, and both sides of the grease trap 1 are sequentially provided with an inspection well 2, a sedimentation tank 3 and a cooling pool 4; the bottom of the cooling pool 4 A reservoir 5 is provided; the reservoir 5 is connected to the manual three-way valve 6 in the inspection well 2 through a drainage pipe, and a water pump 7 is arranged on the drainage pipe; the inspection well 2 is connected to the grease traps 1 on both sides through the drainage pipe and settling tank 3, and a water pump 7 is installed on the drainpipe connected to the settling tank 3; the settling tank 3 is connected to the cooling pool 4 through the draining pipe, and the draining pipe is provided with a water pump 7; in the two cooling pools 4, only One is equipped with cooling water; the inner surfaces of the grease trap 1, the sedimentation tank 3 and the cooling tank 4 are all paved with waterproof ...

Embodiment 2

[0021] A truck cooling pool in an expressway service area, the truck cooling pool includes a grease trap 1, and both sides of the grease trap 1 are sequentially provided with an inspection well 2, a sedimentation tank 3 and a cooling pool 4; the bottom of the cooling pool 4 A reservoir 5 is provided; the reservoir 5 is connected to the manual three-way valve 6 in the inspection well 2 through a drainage pipe, and a water pump 7 is arranged on the drainage pipe; the inspection well 2 is connected to the grease traps 1 on both sides through the drainage pipe and settling tank 3, and a water pump 7 is installed on the drainpipe connected to the settling tank 3; the settling tank 3 is connected to the cooling pool 4 through the draining pipe, and the draining pipe is provided with a water pump 7; in the two cooling pools 4, only One is equipped with cooling water; the inner surfaces of the grease trap 1, the sedimentation tank 3 and the cooling tank 4 are all paved with waterproof ...

Embodiment 3

[0023]A truck cooling pool is set up on the roadside in a highway service area. The truck cooling pool includes reservoirs (I and II), water pumps (①-⑥), sedimentation tanks (I and II), manual three-way valves (① and ②), inspection wells (I and II), grease traps, cooling pools (I and II) and drainage pipes. This cooling pond comprises two cooling ponds (cooling pond I and cooling pond II), is filled with cooling water and puts into use in the cooling pond I, is provided with a cooling water treatment system between the two cooling ponds, and the cooling water treatment system includes two sedimentation ponds ( Sedimentation tank I and sedimentation tank II) and a grease trap, the grease trap is located between the two sedimentation tanks, the reservoir, the grease trap and the sedimentation tank are connected through a drain pipe and a manual three-way valve. Among them, the specifications (length×width×height) of reservoirs I and II are 30cm×30cm×50cm, and grilles are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com