Full analytical model construction method of capacitance type wall shear stress sensor probe

A sensor probe and analysis model technology, applied in the field of sensors, can solve problems such as high requirements for professional knowledge and experience, and reduce the efficiency of sensor design, so as to achieve the effect of clear design ideas and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

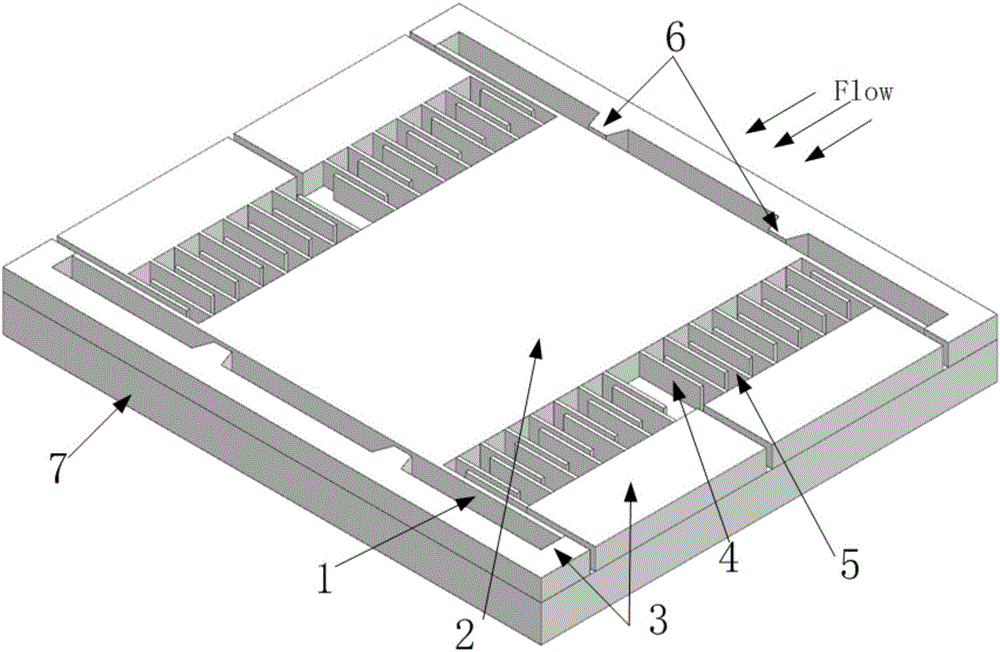

[0054] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0055] The capacitive shear stress sensor involved in the present invention needs to use the symbol and explanation thereof in the establishment process of full analytical model:

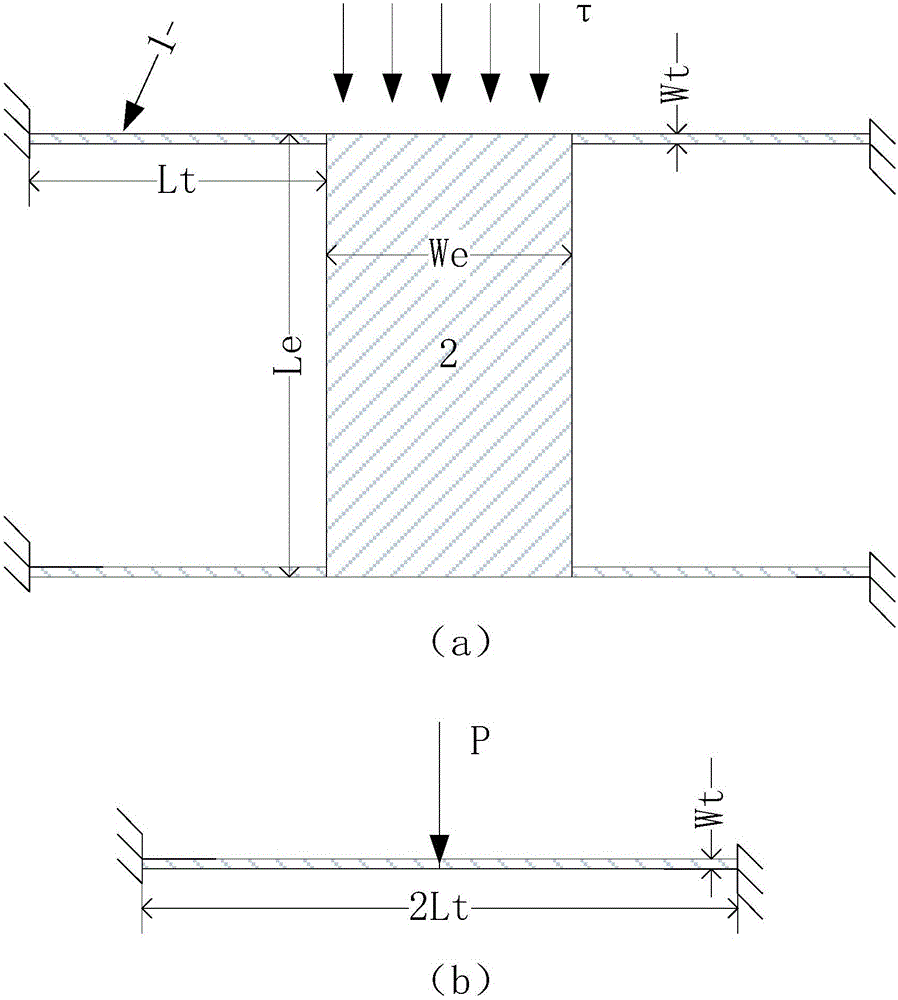

[0056] L t : the length of the elastic beam;

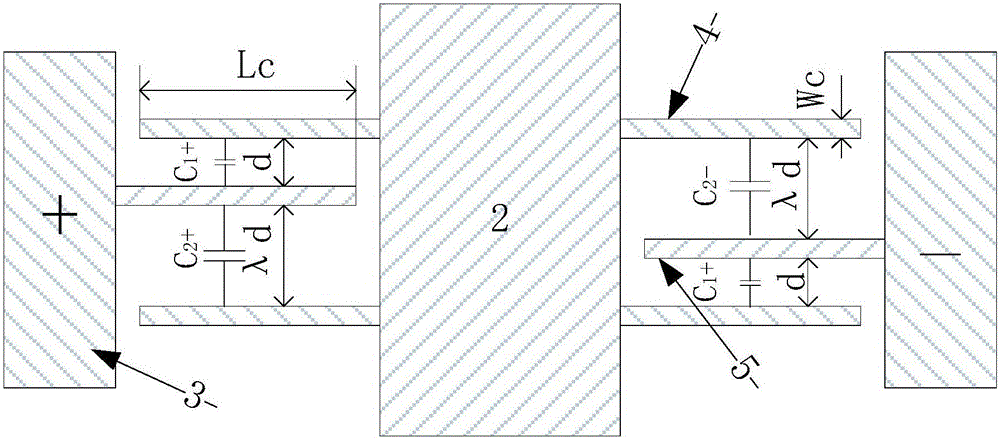

[0057] d: spacing between adjacent combs;

[0058] W t : the width of the elastic beam;

[0059] λ: bias ratio;

[0060] L e : the length of the floating unit;

[0061] W e : the width of the floating unit;

[0062] L c : overlapping length of comb teeth;

[0063] W c : width of comb teeth;

[0064] t: thickness of the device layer;

[0065] N: number of pairs of comb teeth;

[0066] ε: permittivity in air;

[0067] ρ: manufacturing material mass density;

[0068] E: Modulus of elasticity of the manufacturing material.

[0069] The performance index and meaning descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com