Video microscope with electric focusing and zooming and operation method thereof

An electric focusing and microscope technology, applied in the field of video microscopes, can solve the problems of complicated operation of video microscopes, and achieve the effect of enhancing operator experience, increasing efficiency, and optimizing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

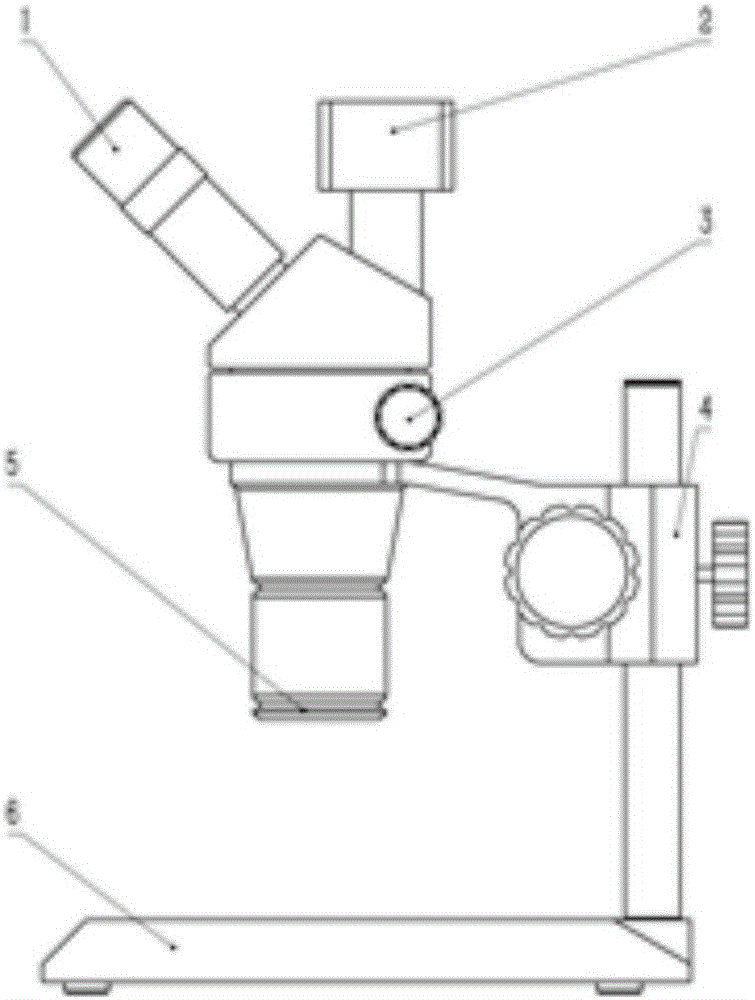

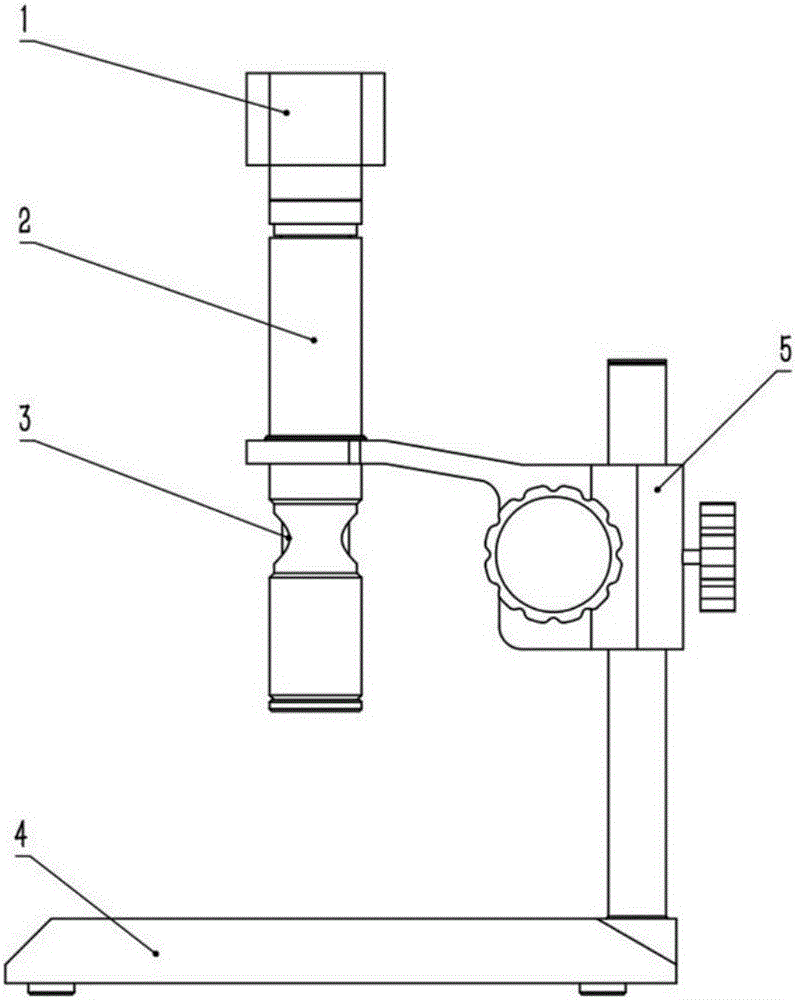

Embodiment 1

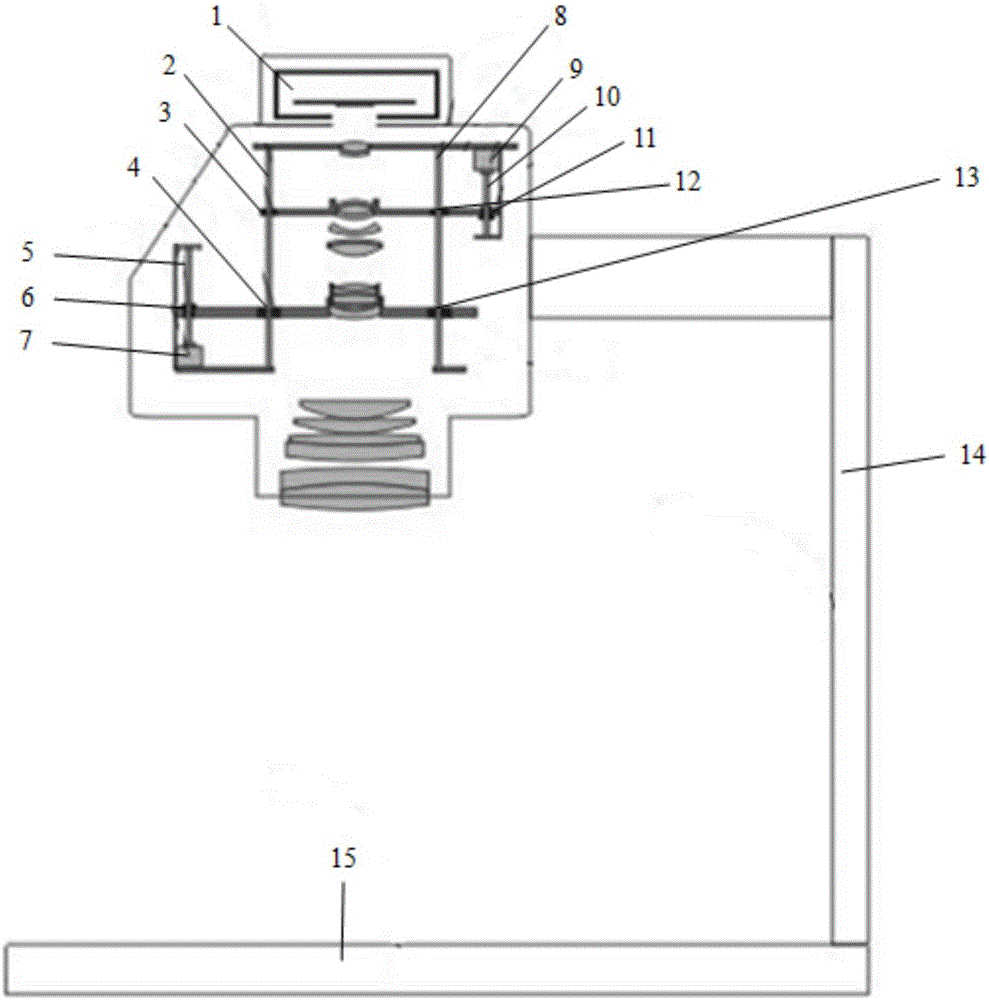

[0038] Such as image 3 with 4 As shown, according to an embodiment of the present invention, a video microscope with electric focusing and zooming is provided, including an image acquisition module 1, a support 14, a sample stage 15, a focusing lens group 16, a continuous zoom lens group 17 and The objective lens group 18, the guide device 2 is connected with the focusing lens group 16 through the guide bearing 3, and is connected with the continuous zoom lens group 17 through the guide bearing (4); the guide device 8 is connected with the focus lens group (16) through the guide bearing 12 Link to each other, link to each other with continuous zoom lens group 17 through guide bearing 13;

[0039] It also includes focusing parts and continuous variable magnification parts;

[0040] The focusing component includes an electric motor 9, a leading screw 10, and a motor transmission part 11; the leading screw 10 is fixed on the electric motor 9, and the electric motor 9 and the l...

Embodiment 2

[0045] According to an embodiment of the present invention, a method for operating a video microscope with electric focus and zoom is provided, and the specific steps are as follows:

[0046] The sample to be observed is placed on the sample stage 15, and the electric motor 9 and the lead screw 10 rotate to drive the lead screw nut 11 and the focusing lens group 16 to move; , to complete the focus, you can get a clear image. Then the electric motor 7 and the leading screw 5 are rotated to drive the leading screw nut 6 and the continuous variable power lens group 17 to move, thereby obtaining an appropriate magnification. The sample image is transmitted to the image acquisition module 1 through the optical path, converted into a digital image and transmitted to the display.

Embodiment 3

[0048] According to an embodiment of the present invention, a program control of a video microscope with electric focusing and zooming is provided, specifically as follows:

[0049]After placing the sample to be observed on the sample stage 15, input instructions (such as focusing range, magnification) to the program on the control panel, and the program sends a signal to the electric motor 9 after conversion, and the electric motor 9 drives the lead screw 10 to proceed according to the program Rotate to adjust the focus; at the same time, send a signal to the electric motor 7, and the electric motor 7 drives the lead screw 5 to perform multiple amplification according to the program. After the sample image is automatically adjusted and zoomed in, the optical path is transmitted to the image acquisition module 1, converted into a digital image and transmitted to the display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com