Green tea processing process

A processing technology, green tea technology, applied in the field of green tea processing technology, can solve problems such as poor tea color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

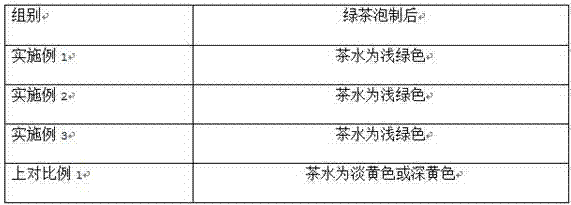

Embodiment 1

[0018] Embodiment 1: Step 1, selection: select fresh, crisp and tender celery, remove the rhizome and only keep the leaves, rinse with clean water, and cut into 3cm long sections;

[0019] Step 2, blanching: adjust the pH of the hot water to 7 with 0.02% Na2CO3 solution, and heat it to 85°C to blanch the selected celery for 3 minutes;

[0020] Step 3, crushing: crush the blanched celery in step 2, and use a strainer to filter to obtain celery juice, set aside;

[0021] Step 4. Centrifugation: Use a high-speed centrifuge to centrifuge the celery juice. The speed of the centrifuge is 4000r / min, and the centrifugation time is 10 minutes. During the centrifugation process, add salt, sodium alginate, honey and citric acid, celery juice, salt, lemon The weight-number ratio of acid, sodium alginate and honey is: 30:1:1:1:1;

[0022] Step 5. Processing: put celery juice into a sphere made of propolis, put old tea and propolis balls into a tea bag to form new green tea, and the weight...

Embodiment 2

[0023] Embodiment 2: Embodiment 1: Step 1, selection: select fresh, crisp and tender celery, remove the rhizome and only keep the leaves, rinse with clean water, and cut into 4cm long sections;

[0024] Step 2, blanching: adjust the pH of the hot water to 8 with 0.03% Na2CO3 solution, and heat it to 95°C to blanch the selected celery for 5 minutes;

[0025] Step 3, crushing: crush the blanched celery in step 2, and use a strainer to filter to obtain celery juice, set aside;

[0026] Step 4. Centrifugation: Use a high-speed centrifuge to centrifuge the celery juice. The speed of the centrifuge is 4000r / min, and the centrifugation time is 10 minutes. During the centrifugation process, add salt, sodium alginate, honey and citric acid, celery juice, salt, lemon The weight-number ratio of acid, sodium alginate and honey is: 30:1:1:1:1;

[0027] Step 5. Processing: put celery juice into a sphere made of propolis, put old tea and propolis balls into a tea bag to form new green tea, ...

Embodiment 3

[0028] Embodiment 3: Step 1, selection: select fresh, crisp and tender celery, remove the rhizome and only keep the leaves, rinse with clean water, and cut into 5cm long sections;

[0029] Step 2, blanching: adjust the pH of the hot water to 8 with 0.05% Na2CO3 solution, and heat it to 95°C to blanch the selected celery for 5 minutes;

[0030] Step 3, crushing: crush the blanched celery in step 2, and use a strainer to filter to obtain celery juice, set aside;

[0031] Step 4. Centrifugation: Use a high-speed centrifuge to centrifuge the celery juice. The speed of the centrifuge is 4000r / min, and the centrifugation time is 10 minutes. During the centrifugation process, add salt, sodium alginate, honey and citric acid, celery juice, salt, lemon The weight-number ratio of acid, sodium alginate and honey is: 30:1:1:1:1;

[0032] Step five, step five, processing: put celery juice into a sphere made of propolis, put old tea and propolis balls into the tea bag to form new green tea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com