Automatic intelligent grease sprayer

A grease-spraying and intelligent technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems such as low anti-corrosion and anti-rust effect of non-long-lasting grease, increased maintenance workload of rail station bolts, and no obvious improvement in operation efficiency, etc. Achieve the effect of improving work efficiency and stability, high-efficiency spraying, and improving work ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

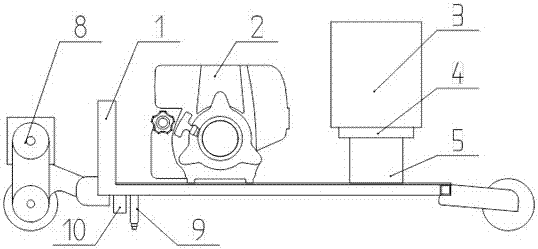

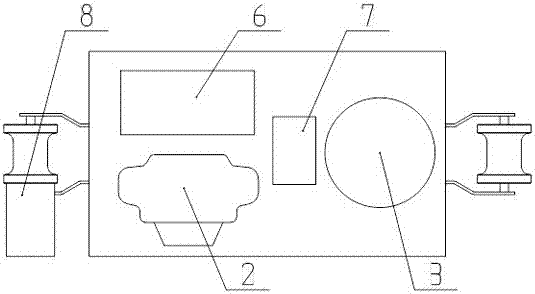

[0029] Embodiment 1: An automatic intelligent grease sprayer, including a support base 1, a grease spray machine and a control system for the grease spray machine are respectively installed above the support base 1, and a running mechanism assembly is installed below the support base 1 8. The walking mechanism assembly 8 at least includes a chain for connecting with the power mechanism, and a traveling wheel driven by the chain; the grease spraying machine includes a grease tank 3 for containing grease, and a plunger pump 4 for providing power for spraying 1. A grease nozzle 9 for spraying grease, the grease tank 3 is connected with the oil inlet of the plunger pump 4, and the oil outlet of the plunger pump 4 is connected with the grease nozzle 9 through a pipeline; the plunger pump 4 is connected by a pump driving mechanism 5 provides power; the control system includes a controller 6 and an inductor 10, the controller 6 is connected to the running mechanism assembly 8, the pum...

Embodiment 2

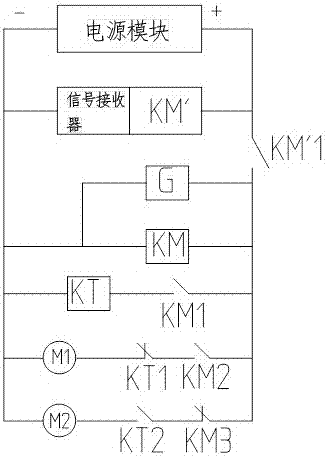

[0030] Embodiment 2: a kind of automatic intelligent grease injector, wherein said controller 6 comprises remote control transmitter, remote control receiver, time relay, intermediate relay, wherein inductor 10 is connected to the coil two ends of intermediate relay KM, intermediate relay KM The normally open contact KM1 of the intermediate relay KM is connected in series with the coil of the time relay KT, the normally open contact KM2 of the intermediate relay KM is connected in series with the normally closed contact of the time relay KT1 and then connected in series with the driver M1 in the pump driving mechanism 5, and the intermediate relay KM The normally closed contact KM3 of the time relay KT is connected in series with the driver M2 of the traveling mechanism assembly 8 after being connected in series with the normally open contact KT2 of the time relay KT. The structures and connections of the remaining parts are the same as those described in any of the foregoing e...

Embodiment 3

[0031] Embodiment 3: a kind of automatic intelligent grease injector, wherein said controller 6 comprises single-chip microcomputer, and the input port of single-chip microcomputer is connected with remote control receiving module, sensor 10 respectively, and the output port of said single-chip microcomputer is connected with LED display module, walking mechanism respectively The driver in the assembly 8 and the driver in the pump drive mechanism 5 are connected. The structure and connection relationship of the remaining parts are the same as those described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com