Labeling mechanical hand based on PCB robot production line

A PCB board and robot technology, applied in the field of automation equipment, can solve the problems of high labor intensity, large changes in fixtures, labeling speed, and insufficient labeling flexibility and reliability, reducing equipment investment and floor space, improving Stability and reliability, firm and reliable label application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

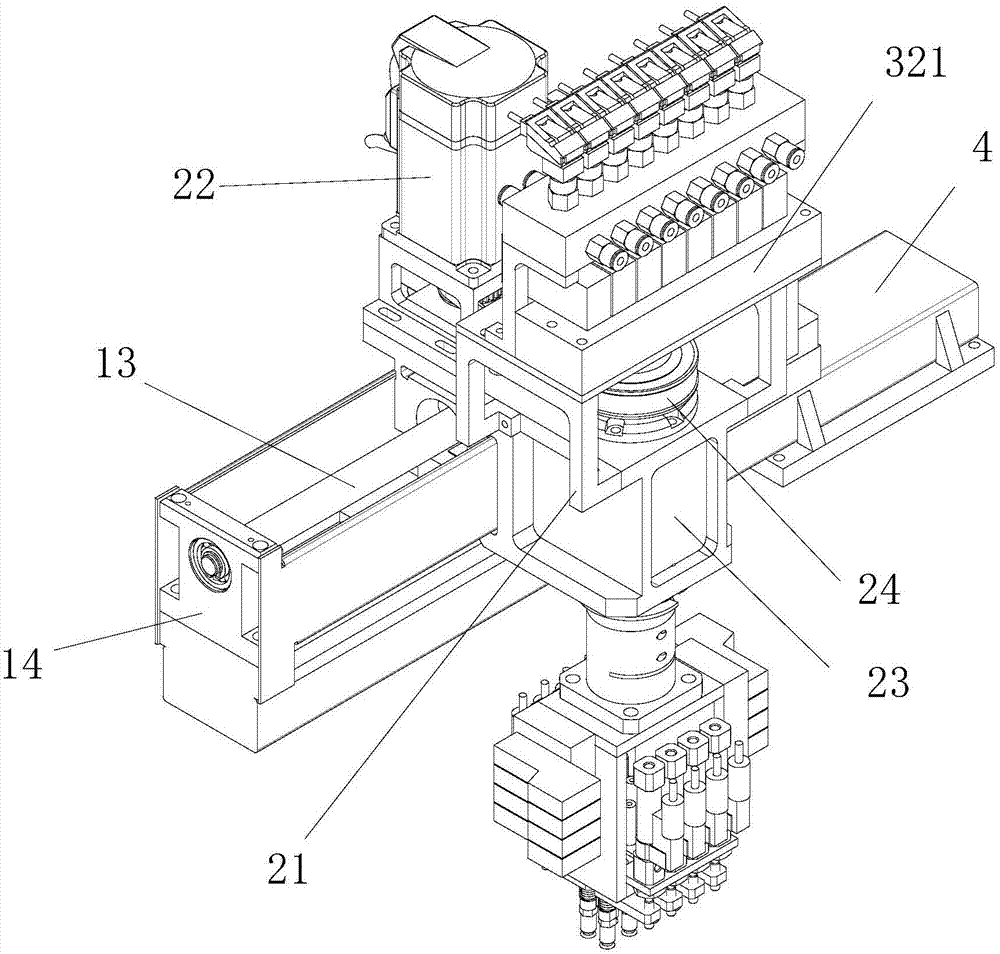

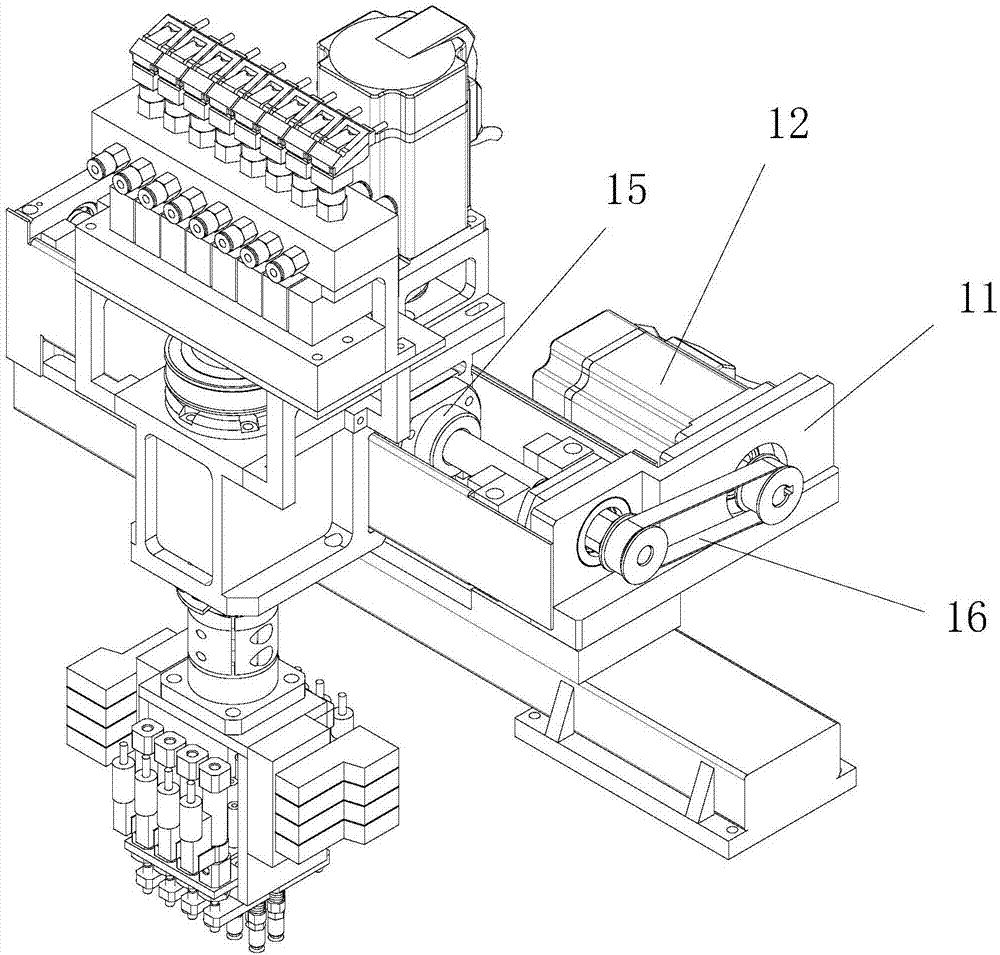

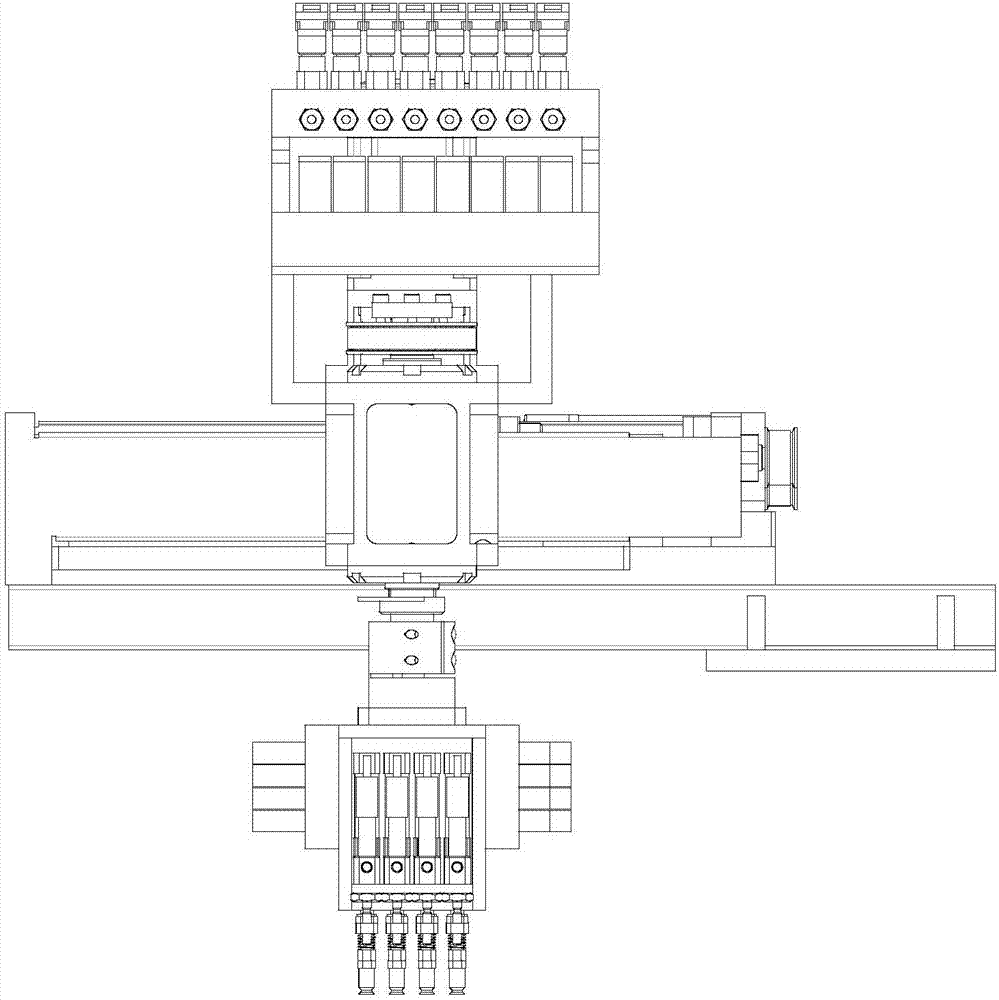

[0040] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the present invention discloses a labeling manipulator based on a PCB robot production line. The labeling manipulator mainly includes a base 4, a first driving device installed on the base 4, a second driving device installed on the first driving device, And the third driving device installed on the second driving device. The first driving device takes the second driving device to reciprocate linearly between the stripping area and the labeling area, and the second driving device takes the third driving device to the labeling area and then rotates at a certain angle according to the process requirements Labeling.

[0041] Specifically, the first drive device includes a motor mounting base 11, a first motor 12, a first screw 13, a screw seat 14, a first nut 15, and a first screw connecting the first motor 12 and the first screw 13. A timing belt 16. The motor mounting base 11 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com