Ship stern propelling device based on magnetic force transmission

A technology for propulsion devices and ships, which can be applied to non-mechanical gear transmission devices, transmission devices using synchronous propulsion components, and engine sealing. It can solve the problems of low sealing reliability, limited layout space, and poor pressure resistance. , to meet the transmission requirements and pressure resistance, miniaturize the structure, and improve the length of the axial contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the drawings and embodiments.

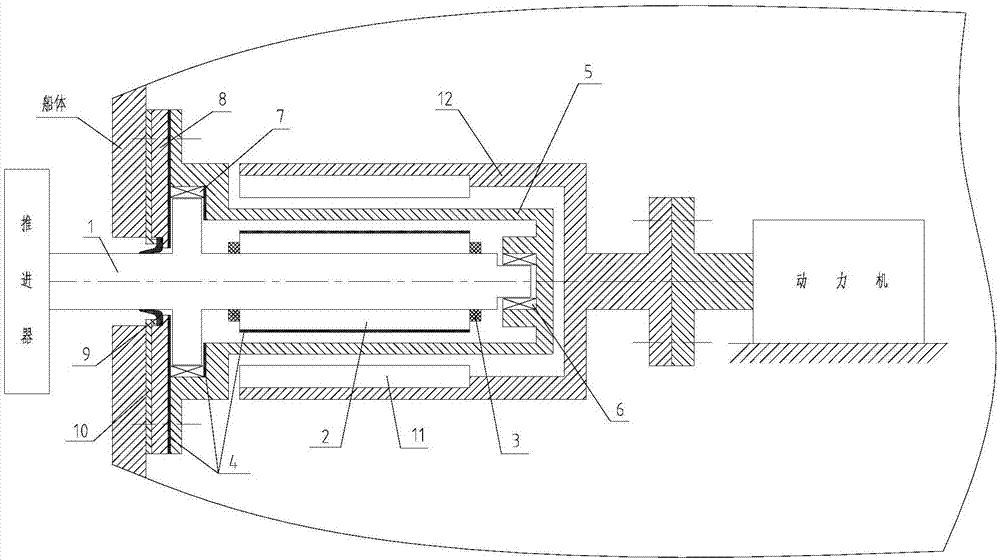

[0022] As attached figure 1 As shown, the present invention provides a ship stern propulsion device based on magnetic drive, which includes an inner magnetic rotor, an isolation device and an outer magnetic rotor;

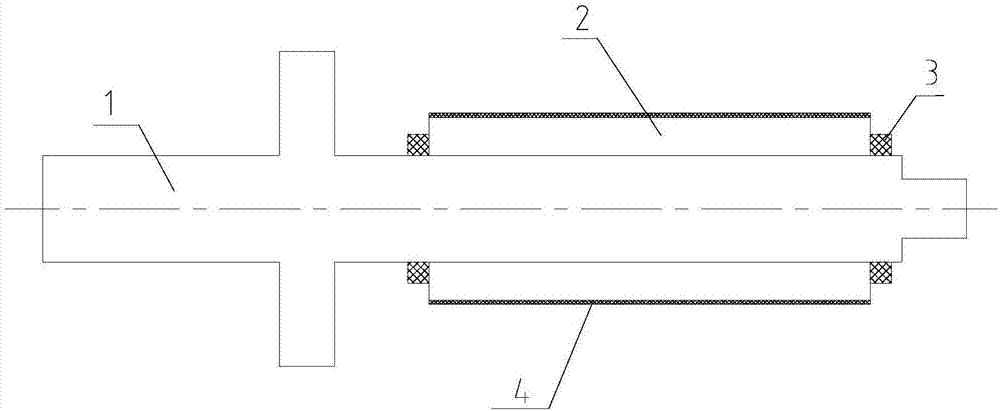

[0023] As attached figure 2 As shown, the inner magnetic rotor includes a shaft 1, an inner magnet 2 and a clamp 3. The shaft 1 has a shoulder. The inner magnet 2 is mounted on the right side of the shoulder. The axial and circumferential limits of the inner magnet 2 are respectively clamped The hoop 3 and the key are connected, and the outer surface of the inner magnet 2 is covered with a non-metallic layer 4.

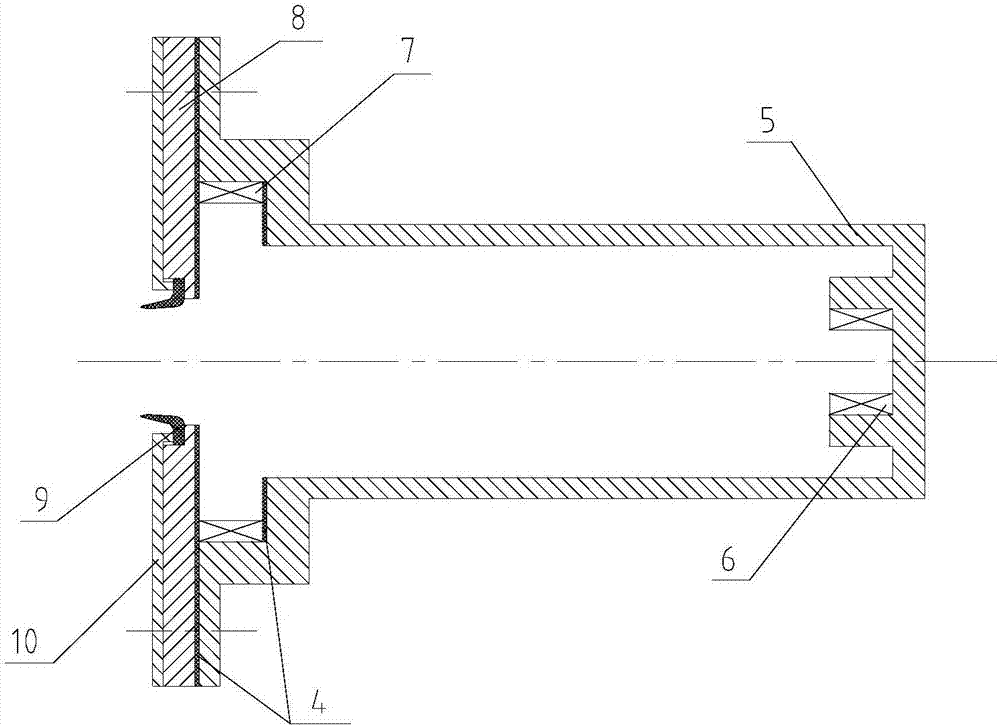

[0024] As attached image 3 As shown, the isolation device includes an isolation sleeve 5, a front bearing 6, a rear bearing 7, a stop ring 8, a shaft seal 9 and a compression ring 10. The isolation sleeve 5 is a shell structure with one end open and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com