Working platform for hydraulic combined anchor drilling rig

A technology of working platform and rock bolter, which is applied in the installation of rock bolts, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of low degree of automation, prone to chipping, affecting roadway forming effect and support performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

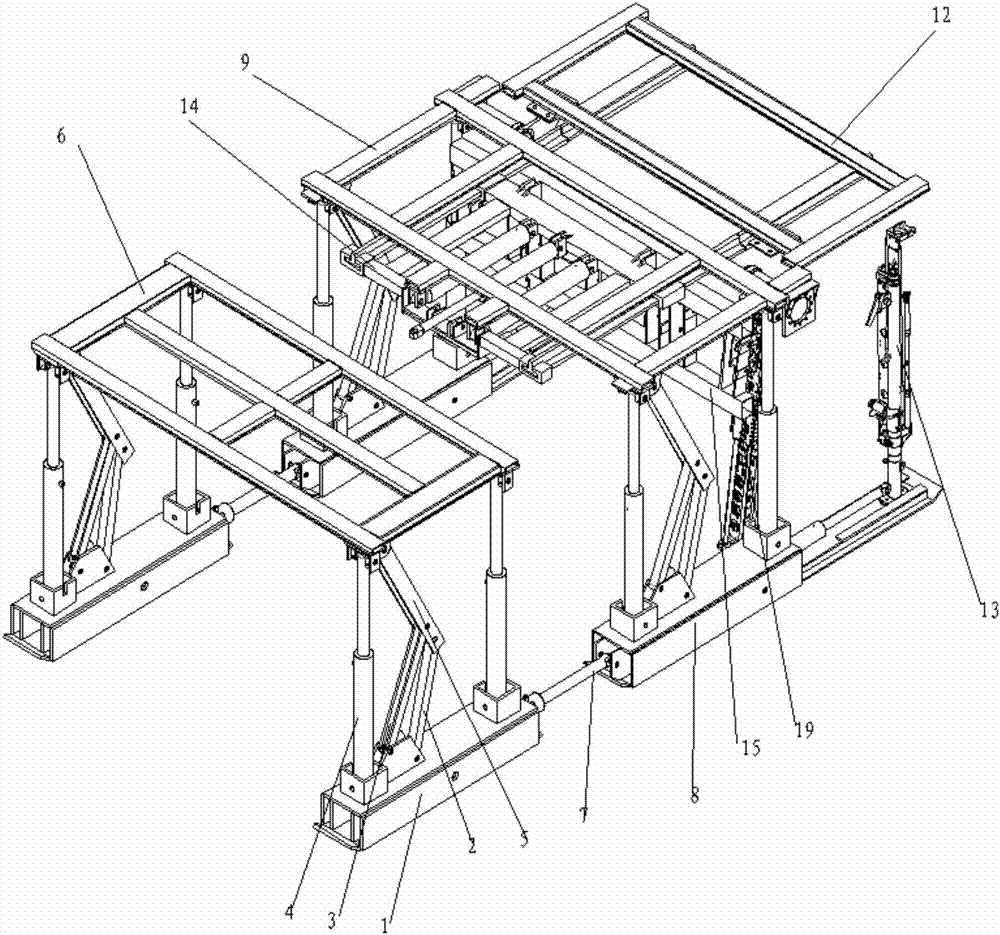

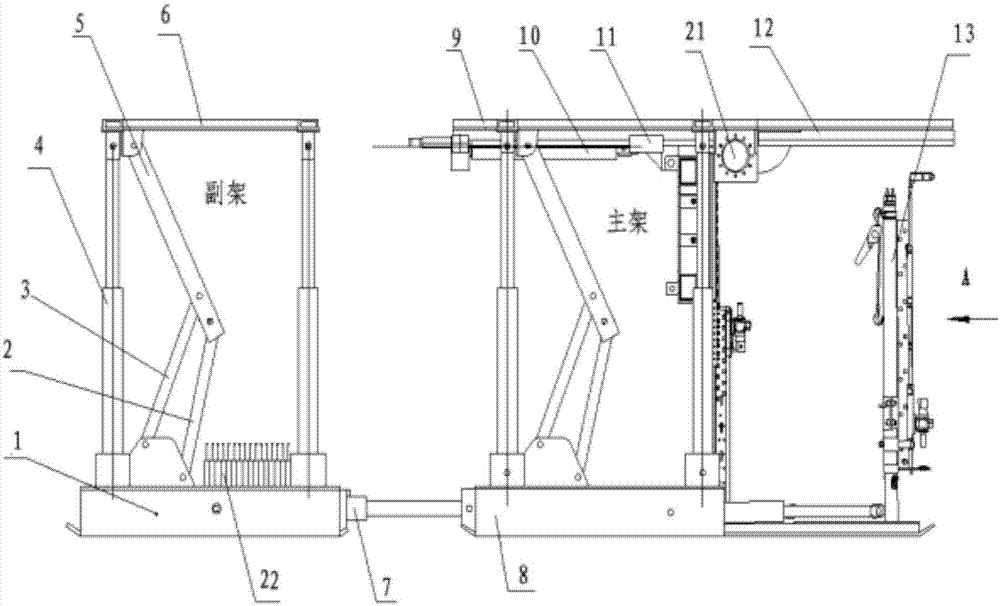

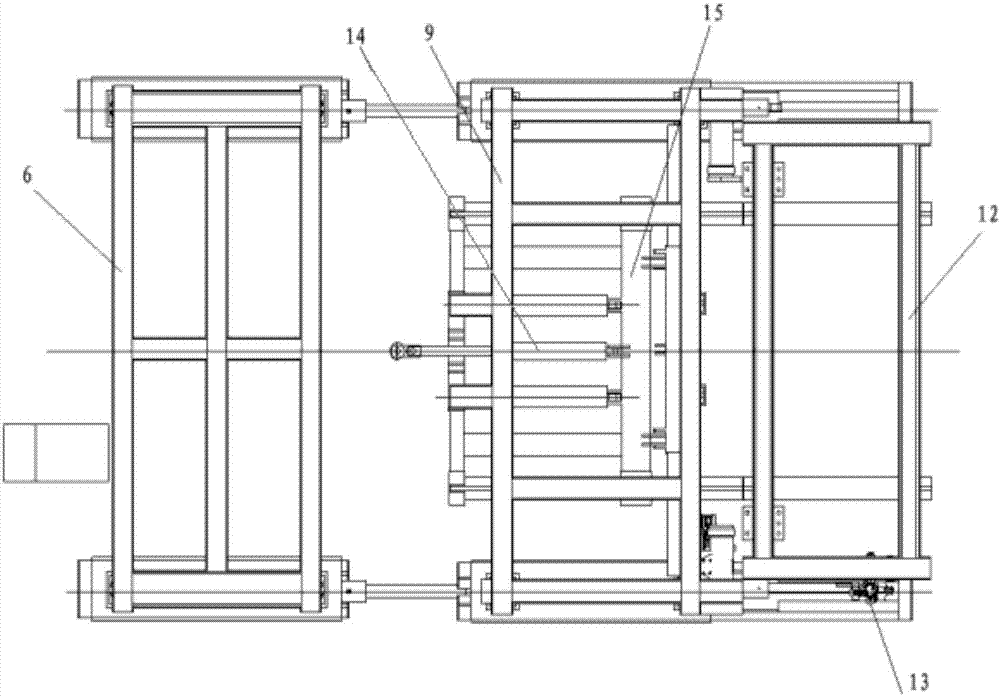

[0018] Such as figure 1 As shown, the platform works by

[0019] (1) The main frame and the auxiliary frame support each other, and move forward by pushing the hydraulic cylinder 7 alternately to support the top, and move forward with a step distance of 0.8m, which is the same as the row distance of the anchor rod.

[0020] (2) After the net-laying front beam 12 rotates 45 degrees downward under the action of the spiral hydraulic swing cylinder 21, the ladder beam and the anchor net are installed on the net-laying front beam 12, and then turned into a horizontal position to complete the ladder beam and the anchor net. Pre-installation of the anchor net.

[0021] (3) The auxiliary anchor drilling rig 13 is pushed out 0.8m under the action of the push hydraulic cylinder 7 embedded in the drilling rig base 8, and the two sides are staggered to complete the auxiliary anchor work.

[0022] (4) On the inverted T shape of the main frame top beam 9 and the net-laying front beam 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com