Double-shaft balancing design method of V8 type diesel engine

A design method and technology for diesel engines, applied in mechanical equipment, internal combustion engine testing, springs/shock absorbers, etc., can solve problems such as damage to instruments and equipment, excessive vibration of the entire diesel engine, loose fasteners, etc., to ensure correctness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

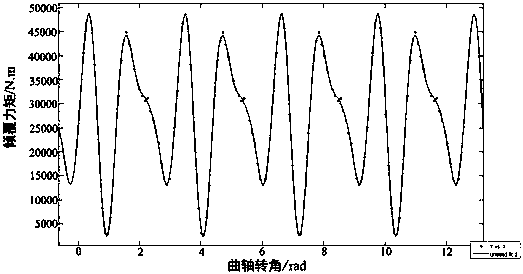

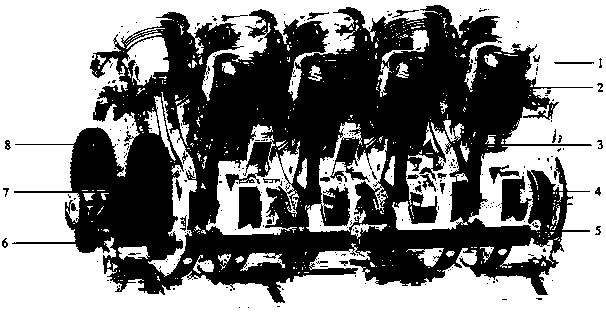

[0028] In this embodiment, the dual-axis balance design method of the V8 diesel engine, the dual-axis balance scheme design of the diesel engine under the rated speed condition is carried out through the method of combining theoretical design and dynamic simulation, and the balance characteristics of the diesel engine are analyzed based on the virtual prototype technology. research analysis.

[0029] This example calculates the balance performance of diesel engines under two crank types (space type and planar type) and four types of cylinder angles (45°, 50°, 60° and 90°), and the calculated content includes the rotational inertia force And torque, first and second order reciprocating inertial force and moment, compare each other and choose the most suitable crank type and cylinder angle for V8 diesel engine. The calculation method of the balance performance is mainly formed by projecting and superimposing the force or moment in the horizontal and vertical directions. The deta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com